Paint and Coating Resins & Polymers

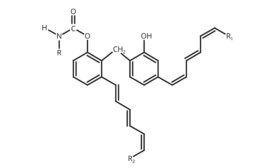

Opportunities for the Alkyd Resin Market

to Create a Sustainable Future for the European Coatings Industry

Read More

Low-Temperature-Curing Powder Coatings System

for New Applications and Robust Process Efficiency

Read More

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing