Buyers Guide

Are you sure you want to leave before submitting your RFP?

Directory & Buying Guide

Our paint and coatings industry directory includes suppliers, manufacturers and distributors of all types of coatings products and services.

Dürr Systems Inc.

Company Profile

Dürr Systems Inc., Application Technology, Clean Technology Systems

26801 Northwestern Hwy.

Southfield,

MI

48033

United States

Phone: (248) 450-2000

Fax: (734) 459-5837

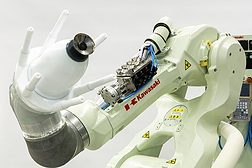

Dürr's industrial products business offers premium application technology for paint and high-viscosity materials, suitable for all industries. Our clean technology systems division offers drying and curing technologies for processes and specialized coatings as well as VOC oxidation, solvent recovery and distillation equipment for industrial processes.

Product Categories

Articles

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing