Featured on Home Page

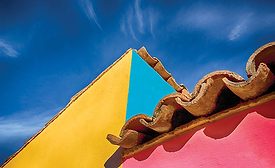

The Emergence of Naturally Sourced Colorants

and Their Role in Advancing Modern Pigment Technologies

Read More

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing