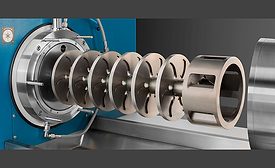

Manufacturing Equipment

Real-Time Polymer Monitoring System

Characterizes Polymer Properties of a Free Radical Batch Polymerization of Methyl Methacrylate

Read More

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing