Industrial Coatings

The Journey to VOC Exemption

AMP becomes the only organic amine to gain the EPA’s VOC-exemption status

January 6, 2015

It’s Time for Data to Drive Compliance

Ensuring Regulatory Compliance in the Paint and Coatings Industry

Read More

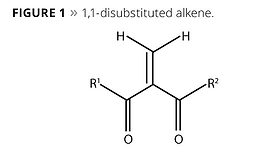

Rapid Room-Temperature-Curing Monomer Platform

Disubstituted Alkene Monomers – Ripe for Experimentation

Read More

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing