Paint and Coating Equipment

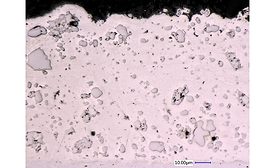

Is the Milling Stage Killing Your Operational and Financial Performance?

Area: Operational Performance Improvement

Read More

Bringing Artificial Intelligence to the Paint Shop

First Market-Ready AI Application for Paint Shops

Read More

In an Ideal World, Color Matching Would Always Be Perfect on the First Try

How to Balance Cost, Time and Quality when Matching a Customer’s Color Requirement

Read More

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing