Paint and Coating Resins & Polymers

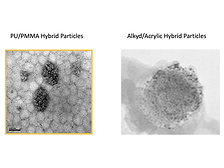

Binder Transfer in Paints and Coatings

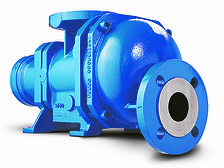

Sealless Eccentric Disc Pump Provides Low Shear, CIP and High Volumetric Efficiency for Binder Transfer Applications

Read More

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

-(1).jpg?height=168&t=1668413861&width=275)

.jpg?height=168&t=1654523773&width=275)