Dispersion Equipment

as it Relates to Plant Quality and Safety

When preparing new facilities, or retrofitting existing ones, it is imperative that plant quality and safety be kept at the forefront of the design and specification of equipment and facilities. The primary contributor to plant quality and safety is the design and selection of equipment; in the coatings industry this is predominantly mixing and dispersion equipment. When operating at an industrial scale, the dangers associated with dispersion equipment are many.

The right piece of machinery for the job helps to ensure a safe working environment, as well as protect the quality of the plant. Items that must be considered are: machine capacity; horsepower; range and limit of machine in terms of what operating parameters are safe, and when a change in these conditions can be potentially hazardous; safety features and retrofits; and monitoring and maintenance equipment.

Explosion-Proof Equipment

Explosion-proof motors and equipment should be used in certain environments where solvents, solvent vapors, potentially explosive dusts and other potentially hazardous materials are or may be present. Explosion-proof equipment can be critical in preventing dispersion equipment damage, plant damage and operator injury. A non-explosion-proof machine should never be utilized in the same space as explosion-proof equipment; solvents and explosive dusts can come in contact with the machine, posing a safety issue. If an environment is intended and used for or with any materials that could potentially pose a safety hazard, all equipment should be explosion-proof rated, and necessary precautions and standards of safety be taken into consideration.

The Right-Sized Vessel

The right size mixing vessel for a given machine will provide superior dispersion when compared to “any old tank” that is “handy” to use, as well as maintaining a standard of safety. Too small a tank for a high-horsepower machine will result in different(unplanned and unpredictable)streamlines in the laminar flow regime, which could impact the quality of the dispersion. Aside from reduced quality of the end product, a mixing tank that is too small for a given operation can be injurious to operators. In the past year alone there have been multiple instances of operator injuries ranging from fracture to dismemberment to loss of life. As OSHA has become increasingly aware of the all-too-common occurrence of these injuries, dispersion equipment suppliers and plant safety managers strive to increase the standards of safety in their facilities.

For example, if a disperser initially intended for use with a 750-gallon tank is fitted with a smaller vessel to produce a batch of 50 or 100 gallons, a number of quality and safety issues will result. A small tank on a large machine poses a significant and extremely dangerous exposure with an unprotected shaft.

First, a smaller container will not be as tall as the vessel that is intended to be used with the machine. When the proper size tank is used, the shaft guard is in contact with the tank cover at the top of the vessel, such that there is no possibility of operator contact with the rapidly rotating, high-torque shaft. If a lower-capacity vessel is used, said vessel will be shorter, and the shaft guard will not fully cover the shaft. To further exacerbate this safety issue, the exposed portion of the shaft is close to arm and hand height, and at a level where one would commonly make additions to the batch, posing a critical safety concern. A shaft guard fitting the height of the mixing vessel, in conjunction with a tank cover, is advised by OSHA. If a smaller tank must be used, a telescoping shaft guard can be employed; this is a suitable setup for accommodating limited lift applications.

Second, inserting a smaller tank than the disperser is designed for will result in a disadvantageous skewing of the recommended mixer and tank sizing ratios. The tank diameter should be roughly three times the diameter of the impeller (or sum of impeller diameters, if multi-shaft equipment is used). By using a smaller tank, the blade diameter is liable to be more than half of the tank diameter. One can switch out the larger blade for a blade of the proper ratio for the tank; however, this will result in a lower tip speed (feet per minute, FPM) if the same shaft rotations per minute (RPM) are used, resulting in decreased mixing and dispersion efficiency.

To maximize time and energy efficiency, one should mix or disperse at the proper FPM for the given application. For example, 5,000 FPM is a standard blade tip speed for particle size reduction and good dispersion; for simple distributive mixing 3,700-4,000 FPM is sufficient. By using the right tip speed and horsepower (and by that, the proper size of equipment) for the given application, one can potentially use less energy, increasing plant quality.

The larger concern with the above set up is of the great horsepower the equipment possesses, and, therefore, in the increased chance of injury and unsafe plant conditions. It is therefore advisable to only use the proper size tank for a given machine. A good rule of thumb is to have 10 gallons of working capacity for every one horsepower of equipment. Falling too far below this gallon-to-horsepower ratio is not advisable for safety reasons; above for dispersion and mixing quality reasons.

Safety Features

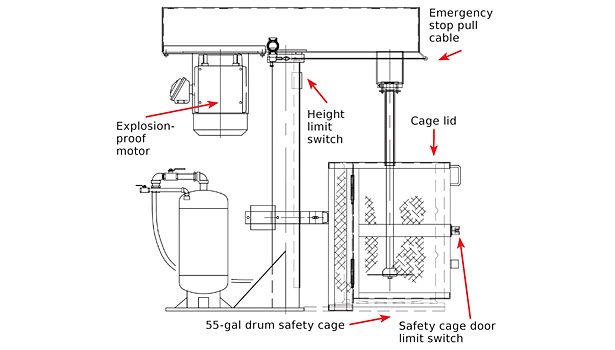

Equipment safety features are key to maintaining plant safety and quality standards, as well as for being in compliance with OSHA and other agency regulations. Safety equipment is continually being improved as new technology is introduced, and regulation requirements change. Some examples of dispersion equipment safety features and protocols are: emergency stop pull cables, shaft guards (as mentioned above), blade covers, maintenance and monitoring systems, tank enclosures, tank and height limit switches, and lockout tag-out programs.

Should the dispersion equipment need to be shut down abruptly, emergency stop pull cables can be utilized. They allow operators to pull a cable – much like those used on buses to prompt the driver to stop at the next bus stop – to halt shaft rotation from any location around the equipment, or when a red shutoff button cannot be reached.

Blade covers are used when a piece of dispersion equipment is offline – such as when a tank is removed, or when cleaning the machine. Due to the fact that disperser blades are generally constructed of thick material and are, therefore, not sharp, the blade cover is primarily in place to protect impellers from damage while exposed. A blade that is damaged can become off-balance, resulting in vibration of the shaft, and potential damage to the entire machine. In the event that blades do become worn down and sharp with age, the blade cover serves the dual function of protecting operators from injury.

Maintenance and monitoring equipment – such as the Myers IMS (Intelligent Maintenance System) – is designed to improve both plant quality and safety. The IMS can be programmed to perform a variety of necessary functions, including recording the time and quantity of additions to a batch, machine operating characteristics (shaft RPM, duration of mixing, et cetera), and prompting operators to perform necessary maintenance and safety checks on predetermined schedules.

Tank enclosures are another option for maintaining plant quality and safety. A cage that completely enshrouds the dispersing vessel, in conjunction with a shaft guard, is elemental to a safe operation. A feed chute allows for additions to the batch while the shaft is rotating by utilizing a variety of cover options (hinged, cone, or hopper style feed chutes); if it is not necessary to add materials while dispersing, a simple telescoping cover can be used. By fully enclosing the shaft and blades, operators are protected; grated feed chutes ensure that only products (not bags, material containers, or other foreign objects) enter the dispersion, protecting the quality of the product. Tank covers are required by OSHA for drum mixers per standard 1910.212(a), and safety cages and feeding systems should be considered for all mixing and dispersing equipment.

Tank and height limit switches ensure that a machine will not operate under unsafe conditions. A tank limit switch prevents a mixer from operating when there is no mixing vessel underneath to act as a barrier between the impeller. Height limit switches automatically stop the shaft rotating if the hydraulic column is lifted to a height that could lead to contact with an unprotected shaft or dispersing blade.

Lockout tag-out programs are a simple and effective means of preserving plant quality and safety, and preventing accidental startup of equipment that is offline for cleaning, maintenance or other reasons.

Conclusion

There are a variety of ways to ensure that a plant is maintaining high standards of safety and quality; the best way to do such is to have many systems in place that will act as multiple protective layers to the safety and quality of a plant.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!