Carbon Black Pigments for a Changing Coatings Market

Coatings manufacturers are constantly required to improve their products to keep up with market trends as well as to keep pace with their competitors. Raw material suppliers, in turn, have had to do the same, by developing and offering new, innovative products that fulfill coatings manufacturers’ requirements for performance and versatility. To that end, Orion has developed a portfolio of new, high-performance grades for coatings. The jettest of these grades is COLOUR BLACK FW 255 (formerly XPB 255).

COLOUR BLACK FW 255, an after-treated carbon black pigment, is characterized by a very narrow distribution of mean primary particle size, as well as a narrow distribution of both primary particle and aggregate size. The after-treatment process generates a functional surface with oxygen-containing groups. When incorporated into a coating system, these groups induce better wetting and dispersion properties. This allows the pigment to impart a more desirable hue and higher level of jetness. Table 1 lists the jetness and hue calculations. An enhanced interaction with polar binders significantly improves the stabilization of carbon black pigments. The volatile content or degree of oxidization is often used to characterize oxygen-containing surface groups. FW 255 has 12% volatile matter at 950 °C.

Test Results

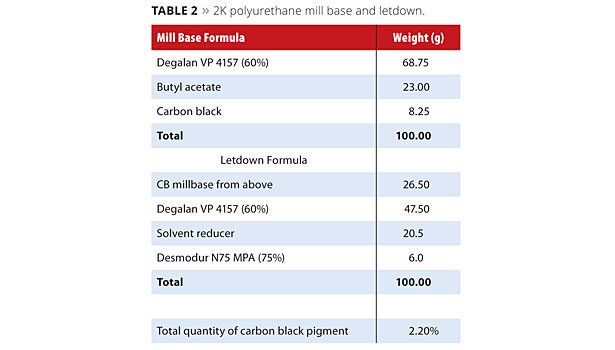

The coloristic properties of FW 255 were tested at a total carbon black pigment concentration of 2.2 percent in a solvent-based 2K PU coating system, based on an acrylic binder (Table 2).

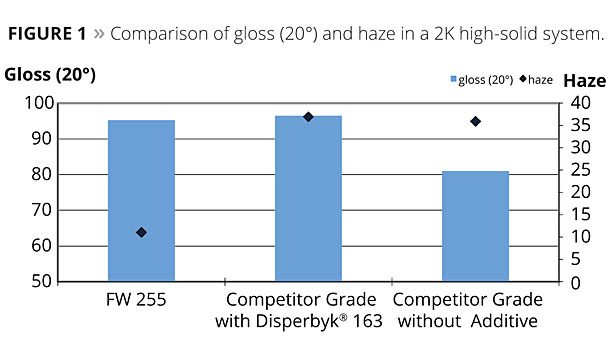

The FW 255 was also tested in a high-solid 2K system against FW 200 and a competitive grade with very positive results (Figure 1). FW 255 showed comparative jetness and much less haze than the competitive pigment. The FW 255 did not contain an additive, as the competitor’s pigment did.

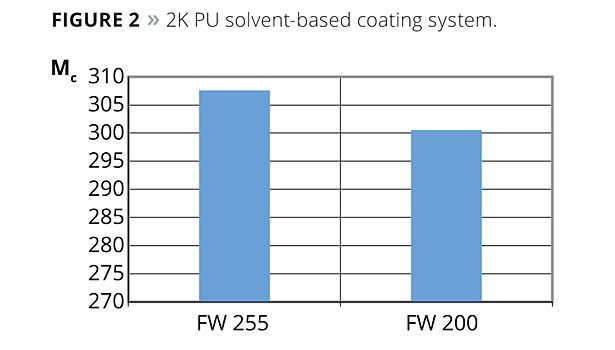

Figure 2 displays the color performance of COLOUR BLACK FW 255 vs. COLOUR BLACK FW 200, a popular high-performance carbon black typically used in automotive applications. FW 255 shows a higher jetness (MY = 302) with less bluish undertone (dM = 5.6) compared with FW 200 (MY = 289, dM = 11.5). The MC, which displays the overall visual impression of the final coating, confirms the significant improvement of FW 255.

The MY value is a measurement of blackness or jetness of a pigment. This does not take hue into consideration. The MC takes into account the hue when measuring the blackness. This allows a customer to select the desired jetness and hue.

The coloristic properties of FW 255 were also tested in a waterborne 1K polyurethane system with a binder-free mill base. To improve the dispersion process, as is typical in waterborne systems, 70% wetting additive on carbon black pigment was used (Table 3).

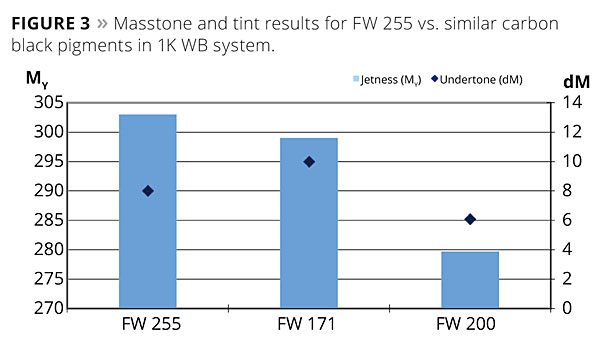

In the tested 1K polyurethane waterborne system (Figure 3), FW 255 displays higher jetness than FW 171 and FW 200. The bluish undertone is slightly less pronounced than that of FW 171, but FW 255 is universally applicable across 1K PU waterborne and solventborne systems.

Due to its performance and viscosity, COLOUR BLACK FW 255 can help formulators achieve a new level of jetness in many coatings systems. The extremely high compatibility in different systems supports the market approach to harmonize and reduce the raw material portfolio.

New Grade for Universal Use

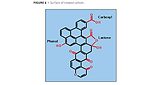

We have also introduced a new universal grade for medium color coatings applications. XPB 412 imparts high gloss and jetness to many coatings applications. This grade of pigment shows comparative jetness and hue to Special Black 4 in a solvent-based system (Figure 4) and superior jetness (Figure 5) in a water-based system. The unique process used in the treatment stage of XPB 412 gives it a distinct advantage over other after-treated grades in waterborne systems. This proprietary after-treatment increases the number of carboxylic groups on the surface, improving the compatibility in various systems (Figure 6).

Conductive Coatings

Newly developed carbon black pigment XPB 545 offers a combination of properties ideal for anti-static and conductive coatings. This material follows the market requirements for extremely high cleanliness and low amounts of heavy metals, and offers a very good balance between surface morphology on resistivity, rheology and color development.

It has demonstrated conductivity on par with many competitive grades and incorporates into systems very easily because of its low oil adsorption. This gives the formulator more flexibility on pigment load levels. The low oil adsorption allows for higher pigment loads. This higher pigment load can increase the conductivity without the typical large increases in viscosity.

High Color, High Performance

We have also developed high-performance pigments for water-based applications and powder coatings. Technical modifications to the furnace black reactor resulted in a new class of carbon black pigment with very small mean particle size, narrow primary particle-size distribution and narrow aggregate-size distribution. The benefit of this unique combination of properties is COLOUR BLACK FW 171, a carbon black pigment with high jetness, a distinct bluish undertone and very good stability in waterborne applications.

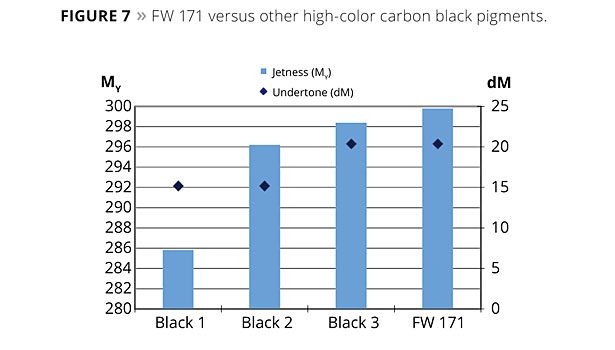

To prove its performance, technicians prepared a typical binder-free mill base and tested the carbon black in a commercially available PUR basecoat/acrylic clearcoat. The concentration of carbon black pigment in the final letdown was 1.8 %. A study compared FW 171 versus other commercially available high-color carbon black pigments (Figure 7). The data shows that FW 171 outperforms the other pigments, providing higher jetness with a strong bluish hue.

Powder coaters have also seen a distinct advantage with FW 171. It provides excellent jetness and compatibility in these systems.

Weathering Tests

High-color, high-performance carbon blacks are required to achieve superior exterior exposure performance and weathering. Although excellent UV performance is inherent with fine-particle-size carbon black pigments, coating manufacturers continue to require two years of Florida weathering data. Unfortunately, weather conditions are unpredictable. The total UV exposure and precipitation in Florida can differ greatly from year to year and create unpredictable results with the same test sample. After exposure to environmental conditions, coated films can also show great differences in acid fastness, depending on whether their initial exposure was in a rainy period or from intense UV radiation (i.e., the primary difference between summer and winter in Florida).

To better predict the performance of high-color carbon black pigments, we use the ADF (acid, dew and fog) weathering test. The ADF test consists of exposing paint specimens to different artificial weathering cycles in specially designed environmental test chambers. Weathering cycles were selected to best reproduce the harsh weather conditions in Florida. Different climatic conditions, such as UV radiation, heat and the application of distilled water or acid rain, alternate during the test. Table 4 shows the average ADF test results for FW 171 in a PUR basecoat/acrylic topcoat system. These results show excellent stability and resistance to weathering, making this pigment an excellent choice for external applications.

Conclusion

The increasing demands of OEM and industrial coatings fuel the need for high-performance pigments that are also compatible with a broad range of coatings formulations. This, along with the growing demands for conductive coatings and the increasing use of waterborne systems, will continue to drive the market for new, innovative pigments.

Acknowledgements

Thomas M. Papasso, Orion Engineered Carbons LLC; Alessandro Vulcano, Orion Engineered Carbons GmbH; and Dr. Yann Wolf, Orion Engineered Carbons GmbH.

References

1. Lippok-Lohmer, K. Farbe und Lack(1986) 92 11, 1024-1029.

2. TI 1204, “Method for Measuring Blackness of Pigment Blacks,” Degussa (2001).

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!