Active Nanoparticle Inks

During the last decade, the University of Grenoble and the University of Marseilles made significant discoveries in the areas of materials conductivity and their chemistry. Genes’Ink Rousset, France, with their highly technical staff, led by their experienced director, has been able to capitalize on these discoveries and create patented inks and coatings for the electronics industry.

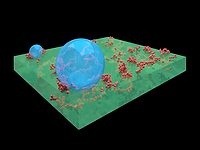

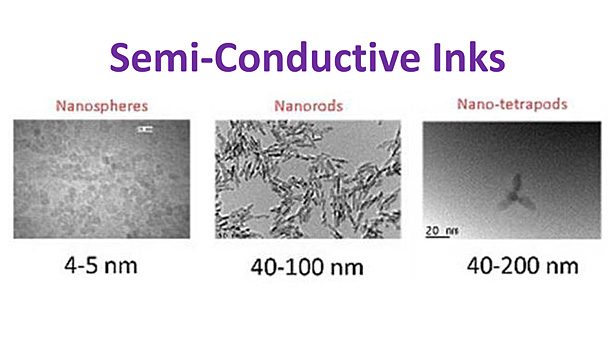

Genes’Ink offers three main product lines: silver conductive, zinc oxide semi-conductive, and security coatings and inks. In each case, these coatings and inkshave two main benefits: a wet deposition process and the use of nanoparticles. These both allow the reduction of raw material quantities and also the modulation of the deposits depending on the technique used, the nature of the substrate and the final application. In addition, the combination of the wet deposition process and nanoparticles ensures a completely safe product without risk to the operator or release of nanoparticles into the atmosphere. Genes'Ink has defined this policy in the development of its inks to guarantee users an economic, safe and versatile solution.

The wet deposition processis the heart of the innovation; opportunities in application areas have skyrocketed in the past few years, and the coatings and inks can be applied using most coating processes and printing techniques. This technology is the key for many up and coming industries, such as the electronics industry or the solar industry, as itensures competitive price and product performance. This technology allows for increased productivity while reducing the amount of deposited product. The deposit can now be perfectly uniform with a thin film on various substrates. Nevertheless, it is imperative to link these effective techniques with adequate and compatible chemistry to guarantee an optimum result. Genes'Ink offers coatings and inks that meet the requirements defined by application process. To this end, Genes'Ink has developed a unique expertise in the formulation field that allows it to offer the market unique ranges of ready-to-use coatings and inks compatible with different processes of application while ensuring optimum properties to the final thin film.

Theproducts have many advantages that make them easy to use. They are perfectly stable colloidal suspensions containing active nanoparticles. Therefore, they reduce the amount of raw material and thus limit the costs without modifying the material’s physical properties. Genes'Ink formulation knowledge allows for adapting and adjustingthe nature of the solvent and additives depending to the application method and the substrate. This translates to a perfect control of the viscosity, the surface tension, and the sintering temperatures of all the coatings and inks. Incredible bonding to a range of substrates is achieved with the products.

It is crucialto master both the synthesis of nanoparticles and their formulation in coatings and inks in order to meet the requirements of customers. This is why Genes'Ink made ??thebold choice to control all stages of manufacturing, from the synthesis of nanoparticles to their formulation, to ensure high-quality inks.

The two main product lines perfectly illustrate this point. First, the silver conductive coatings and inks are better performing than the traditional silver pastes, in particular in RIFD applications, which leads to a decrease in the amount used while maintaining or improving the performance. This gain is significant and is part of the current policy of reducing the consumption of materials such as silver to prevent a global shortage in the next decade. In addition, Genes'Ink has developed a silver ink with low sintering temperatures (< 150 °C), which allows thin deposition on paper or plastic substrates that are media for tomorrow's electronics. Second, the zinc oxide semi-conductive ink, linked to printing or coating, plays an important role in OLED display. Compared to the conventional sputtering process, this association allows for the deposit in one pass of a perfect and uniform thin layer of ZnO (thickness range: between 50 nm and 500 nm depending to the final application) over large areas in shorter time (20s vs 40 min). It is thus possible to cover more than 200 m² of display with one liter of ZnO ink produced by Genes'Ink.

The inks open up new prospects for coating applications because these are not only compatible with so many deposition processes but also fit the many substrates types and the final product design. With its expertise in nanotechnology as applied to coatings and inks, Genes'Ink should be of interest to any user of coatings in the developing electronics and solar fields.

For more information, visit www.genesink.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!