Solids Analyses for Water- and Solvent-Based Coatings

Automated %NVM method – comparable to ASTM procedures

Solids analysis (percent nonvolatile material by weight or %NVM) in the coatings industry is determined for a variety of reasons. Suppliers to the industry frequently sell materials based on the solids content. Accurate solids determinations are critical to their bottom line and their customers’ satisfaction.

EPA regulations mandate that VOCs must be recorded and be at compliant levels. VOC measurement involves determining the solids content of the material, but the solids content is only part of the VOC determination procedure. The water content, determined by Karl-Fischer titration or gas chromatographic techniques, is also necessary to calculate VOC.

Professional painters look at the solids content as a key indicator of paint quality. Thickness or viscosity alone is not a good barometer, as this may only indicate the amount of thickener (rheological additives) in the formulation. As a troubleshooting measure, solids analysis is performed. For example, a batch reading low in viscosity may have too much water/solvent, or the thickener (level) may be incorrect. A solids test will help solve the problem.

Traditionally, solids testing has used the American Society for Testing and Materials (ASTM) oven procedure in a lab environment. There was a need to transfer this testing to the production area where adjustments could be made very quickly. Since many quality control (QC) labs are required to perform sophisticated analyses, production facilities are taking over the relatively simple task of routine solids determinations. Ideally, a production facility should use a solids analyzer that is fast, simple to operate and has the same level of accuracy as achieved in the lab by traditional ASTM procedures.

The Mark 3 solids analyzer can be used on the production floor with this type of accuracy and is designed to run a test with a simple one-button operation. The industry’s goal has been to reduce the cycle time required for determining solids by conventional means. Traditional procedures take 60 min at 105 °C to 110 °C in an oven, and require both pre-and post weighing of the sample pan and sample (ASTM designations: D2369 and D2926-80). With this lag time, production batches must wait for analysis prior to further processing or shipment.

Companies are seeking solids analyses that can be performed in minutes so that adjustments to the batch or process can be accomplished with minimal delay. The Mark 3 solids analyzer typically takes between three and 10 minutes depending on the volatile/moisture content and viscosity of the material.

How the Analyzer Works

With the footprint of a laptop computer, the solids analyzer is basically an automated oven that internally tracks the rate of the sample’s weight change. The instrument automatically tare weighs the empty sample pan and filter paper, and prompts the user to apply an ideal weight of sample onto the pan. Upon lid closure, the instrument will capture the initial weight of the sample and begin the test.

Once a pre-programmed endpoint criterion of the allowable weight change (or less) has been met, the instrument will finalize. Upon completion, the unit will audibly signal the end of the test, print the results, store the data internally and can also be real-time transferred to the company’s computer or LIMS system.

The instrument will guide the user to apply a consistent sample weight for every test. This is known as the ideal weight feature. After the user applies the sample and closes the lid, the instrument will heat to the pre-set temperature and is maintained +/- 1 °C. The temperature can be programmed from ambient to 210 °C. Each resin or coating can be programmed and stored in memory by name. This allows for complete documentation of up to 300 different materials, both on the print-out, internally in statistics and optionally downloaded externally.

Variable Settings

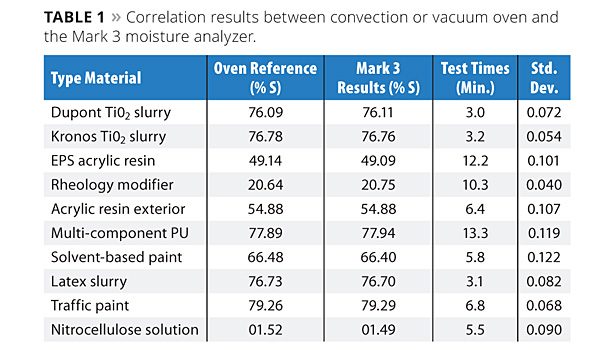

The variables programmed for each type of material within the solids analyzer include a test temperature, an end-point setting and an ideal sample weight. Sartorius develops all of the settings for the customer’s materials. This is done in the Sartorius applications lab. The Mark 3 analyzer results are compared to ASTM or other referenced methods. This is typically a forced-air oven or vacuum oven. The instrument is compared to this reference value to verify the accuracy and precision of the analyzer. Accuracy is stated by the average of repeat tests compared to the reference value, while precision is established by the standard deviation of repeat tests on the Mark 3 (Table 1).

Temperature

The instrument will ramp up to the pre-set temperature and maintain that (+/-1 °C) for the duration of the test. A temperature is established to volatize the solvent and water without degradation to the sample and matching the referenced results.

Endpoint Setting

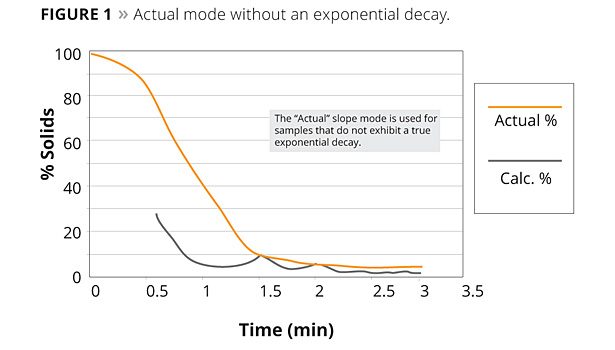

This feature determines when the test will finalize. A window of time and a percent of the sample’s initial weight are the two variables within the endpoint setting that are used to program the instrument for a given material. In the “Actual” mode, time is the window that the instrument uses for a programmed rate of change (percent of initial weight) to finalize. The increment that the unit uses for the percentage of change is one third of the programmed window. For example, if the instrument were programmed at 0.10% over one minute, the unit would look back every 20 seconds over the most recent one minute period to see if a 0.10% rate of change or less had occurred. At 0.10% or less rate of change, the unit would finalize. A rate of change greater than 0.10% would force the instrument to run another 20 seconds before looking back again at the most recent one-minute window. This ensures that the sample will be heated to constant weight (Figure 1).

In the “Calculation” mode, the instrument uses the time window and percent features but in a different fashion. Internally, when the calculated mode is enabled, a macro is activated that predicts the asymptote or endpoint of the test. In one-third increments of the programmed time or window, the instrument logs the calculation. When the latest three calculations agree within the pre-programmed percentage, the instrument will finalize on an average of the latest three predictions. The drying characteristics of the sample must exhibit an exponential decay for the calculation mode to be of benefit. Because the calculated mode predicts the remaining moisture along the base of the curve for a given sample, test times can be dramatically reduced. Further, because the unit averages the latest three calculations, results are typically more consistent and result in improved standard deviations (Figure 2).

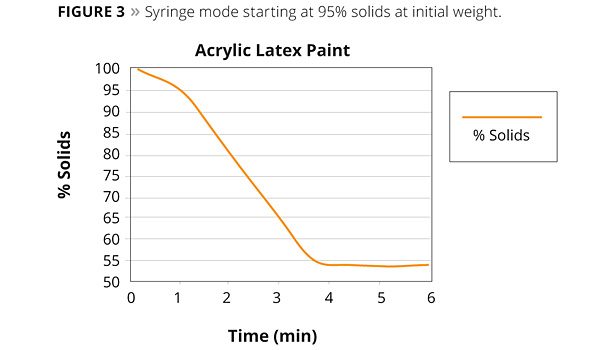

Many coatings and adhesives, however, have volatiles that flash off at the start of the test. For these samples types, the “Syringe” mode is recommended in the actual mode. To accurately capture an initial weight of these volatile samples, Sartorius developed the “syringe method” in the Mark 3 solids analyzer. Using this method, the instrument guides the user to pre- and post-weigh a syringe filled with sample. The initial weight captured by the instrument is determined by the weight difference of the syringe. No manual calculations are required on the part of the operator (Figure 3).

Ideal Weight

This feature guides the user to apply a consistent sample weight for each and every test. Between 90% and 109% of the programmed ideal weight, the instrument will provide an audible signal and display “close door.” Typical sample sizes range between one and three grams. However, determination of the specific ideal weight is on the type sample being tested.

Summary

All companies today are embracing quality standards and are also faced with increasing work loads. Instrumentation developments that provide accurate data and significantly shorten analysis time are desirable and necessary. This is particularly important when the data determines whether production batches can be shipped in a timely manner or whether process corrections are required.

Sartorius offers no-charge instruments to any customer interested in evaluating the Mark 3 at their site. For more information, visit http://sartorius-omnimark.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!