Solar-Reflective Colorants

for Exterior Buildings and Facades

The intent of using solar-reflective coatings is to reflect a significant amount of solar radiation away from colored surfaces to keep them cooler. Cooler surfaces are beneficial to materials and users in many ways. They can help reduce energy costs through lower demand for air conditioning in hot climates. Thermal stress in construction materials is reduced, thus contributing to better durability of temperature-sensitive materials. Cooler surfaces on clothing, helmets or other objects that come in contact with human skin are equally attractive for people at work or participating in leisure activities. Finally, some national restrictions or regulations already enforce the application of solar-reflective surfaces with the intent of protecting the environment and limiting the so-called Urban Heat Island Effect.

“Solar heat management” is the term used when applying solar-reflective colored coatings. It implies that heat build-up is minimized and, at the same time, the surface color is matched to the desired effect. Solar heat management can be beneficial for numerous applications, including architectural and decorative paint applications, such as roofs, façades, exterior insulation finishing systems (EIFS) or window frames. It is equally useful for general industrial paints used in construction or marine applications, or in the leisure sector, including outdoor furniture. Automotive and transportation applications include car body and parts, seats, dashboards, trains, busses, trucks or caravans.

This article reviews the function of near-infrared (NIR)-reflective pigments in colorants to keep objects cooler. Factors that affect the heat-reflective performance of colorants are discussed, particularly focusing on how the total solar reflection (TSR) value is measured and the conclusions that can be drawn from the measured results. Solar-reflective colorants and Novapint D façade colorants mentioned below are produced by Chromaflo.

Solar Reflectance

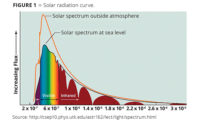

The aim of solar-reflective coatings is to maximize the solar reflectivity of the coated surface. Reflectance is achieved by the physical back-scattering of radiation through pigment particles. This is well-known for the visible spectral range, where the spectral scattering of pigments controls their color appearance. However, solar radiation not only comprises the visible spectrum of wavelength range 400 to 700 nm, but also the UV (< 400 nm) and NIR (700 to 2,500 nm). The latter dominates the overall irradiated solar energy by more than 50 percent.

Calculating Total Solar Reflectance

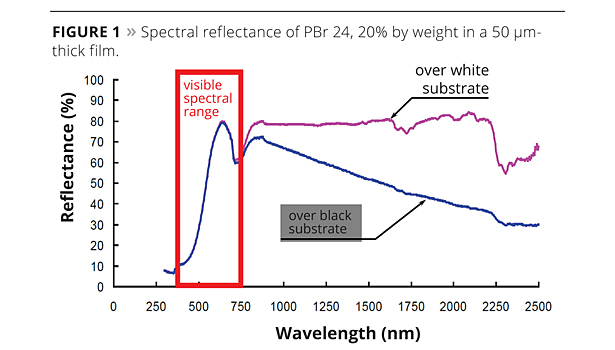

To quantify the solar reflectance of a pigmented film requires knowledge about its reflectance over the entire solar spectral range. An example of Pigment Brown 24 (PBr 24) is given in Figure 1. Multiplying the spectral irradiance with the spectrally corresponding pigmentation reflectance yields the reflected power for every wavelength, typically performed at steps of 5 nm. Successive summation from 300 nm to 2500 nm and normalization of the overall incoming solar power provides the overall reflectance of the pigmented film for the incoming solar energy. This is the TSR value (sometimes referred to as the SR value). For the reflectance spectrum of PBr 24 “over white substrate” (Figure 1), the calculation using the solar spectrum results in a TSR of 64%.

TSR is typically expressed as a percentage. Typical white coatings exhibit a total solar reflectance of 75% or greater. A white coating with a total solar reflectance of 75% by definition will absorb 25% of the incident energy. A black coating based on carbon black pigmentation may have a TSR as low as 4% and therefore will absorb 96% of the incident solar energy.

Pigment Physics in the Solar Spectral Range

The scattering efficiency of pigment particles is a function of the ratio between particle diameter and wavelength of the scattered radiation (Scattering efficiency = particle diameter/wavelength of scattered radiation).

According to Figure 1, the pigment’s scattering in the visible spectral range is sufficient to cause perfect hiding: the reflectance over black and white substrate is identical. However, the longer the wavelength of radiation compared to the pigment particle size, the worse the scattering power of the pigment. In the case of PBr 24, a significant amount of NIR radiation can transmit through the pigmented film onto the substrate. The radiation will stick there if the substrate is absorbing (“black”), otherwise it will be reflected. Consequently there are two separate TSR values: 64% over white, 55% over black. This effect is only caused by NIR. The color appearance, which is only caused by visible wavelengths, remains the same over both substrates.

EIFS Façades

Architects have seemingly endless choices when it comes to façades for commercial buildings and homes. Not only are there many materials available with varying colors and textures, but there are also a number of environmental and functional properties to consider. Today, EIFS are a popular, highly effective way to insulate a building to achieve significant energy savings.

EIFS are multi-layered exterior wall systems that are used on both commercial buildings and homes around the globe. They provide superior energy efficiency and offer much greater design flexibility than other cladding products. While similar in appearance to stucco, EIFS are exterior cladding systems that consists of components and installation requirements very different from traditional stucco, as shown in Figure 2.

While there are multiple manufacturers of EIFS systems, they typically consist of the following five components:

- Insulation board, made of polystyrene or polyisocyanurate foam;

- A specially formulated adhesive and/or mechanical attachment of the insulation to the substrate;

- Glass fiber reinforcing mesh;

- A durable, water-resistant base coat, which is applied on top of the insulation and functions as the weather barrier;

- An attractive and durable finishing coat – typically using acrylic co-polymer technology – which is both colorfast and crack-resistant.

Traditional Color Selection

EIFS manufacturers specify the selection of a finishing coat with a light reflectance value (LRV) of at least 20. The use of dark colors (LRV <20) is not recommended. LRV is a measurement that tells you how much light a color reflects and, conversely, how much it absorbs. LRV runs on a scale from 0% to 100%. Zero represents absolute black, and 100% a perfectly reflective white.

Two issues need to be addressed when using an acrylic finish with an LRV of less than 20:

- Possible damage to the expanded polystyrene insulation board;

- The likelihood of fading or color changing on darker color finishes.

The first issue is a functional problem and can affect the performance of the EIF system. The second issue is an aesthetic problem that does not affect the performance of the system but is an undesirable outcome.

Possible Damage to Insulation Board

The foam plastic insulation used in most EIF systems consists of expanded or extruded polystyrene board. The producers of the polystyrene boards recommend a maximum service temperature of 74 °C (165 °F). At temperatures higher than this value, the boards begin to deform.

For this reason, the use of dark color finishes over the polystyrene boards should be avoided to prevent damage to the insulation boards. Energy absorption of a dark color finish is one of the factors to be considered, but it is also important to take into account the overall climate and the orientation of the relevant surface. This is why a number of EIF system manufacturers recommend a finish with an LRV of at least 30%. Colors with a lightness value of 30 or greater are typically safe to use over an entire EIF system in any geographical area and climate.

Color Fading

Gradual changes in color or fading are primarily due to the color pigments used in the coating. Lighter coatings typically are formulated with inorganic pigments.These inorganic pigments tend to be duller and weaker in tinting strength but are very stable and not easily broken down by exposure to UV light.

To achieve darker colors, it is sometimes necessary to formulate with organic pigments. In some instances, these pigments may be susceptible to UV light degradation. If a certain organic pigment needs to be used to achieve a particular dark color, and if this pigment is prone to UV degradation, then fading is almost a certainty.

LRV versus TSR

Architects, builders or homeowners may not want to limit themselves to white or pastel colors to decorate a building. Recent tastes and trends show that demand for dark wall colors is high.

The LRV of a color indicates only how much visible light of that color will be reflected. Black has an LRV of 0% and absorbs all light, meaning that black surfaces can get very hot. In contrast, white has a LRV of 100% and keeps a building light and cool. All other colors fit between these two extremes.

The TSR value, on the other hand, takes into account the total amount of energy irradiated by sunlight, not just in the visible range. Therefore, two objects can be identical in visible color, while possessing different reflective characteristics in the NIR region, with one remaining cooler on exposure to sunlight than the other.

This can lead to a situation where two colors can have identical LRVs but dramatically different heat build-up, depending on whether or not the pigmentation reflects in the NIR range. For EIF systems, TSR or heat reflectance is more important than simple light reflectance. Below, we will demonstrate that it is possible to formulate dark colors with LRV values <30 by using either specially developed solar-reflective pigments or regular inorganic pigments with inherently good TSR properties. Taking this into account, we can conclude that the LRV should not remain the sole factor when deciding which colors can be used for EIF systems.

NIR-Reflective Black Colorant for Façades

Since the TSR value covers the entire range of radiation between UV and NIR, black pigments show systematically lower TSR values than white pigments. Carbon black, the most commonly used black pigment (PBk 7), strongly absorbs invisible NIR radiation. For façades including EIF systems, we recommend the use of colorants containing inorganic pigments due to their excellent weather- and light-fastness properties. This is why colorants containing the inorganic oxide black pigments such as PBk 11 and PBk 33 are commonly used.

In March 2012, Chromaflo introduced the first NIR-reflective colorant, Novapint D-803, containing a functional NIR-reflective pigment PBr 29 (chromium iron oxide) from BASF. Since Novapint D-803 is a mono-pigmented colorant, the TSR value is higher while the blackness intensity is lower compared to carbon black. Novapint D-803 was developed for in-plant tinting of water-based, high-quality façade systems to create cool surfaces on roofs through façades, for example. Novapint D colorants are compatible with synthetic resin, silicone, and silicate-based paints and plasters.

Research Project

As we were unable to find theories to predict the NIR-reflectivity properties of different black pigments, we set up our own research project for the synthesis and evaluation of the NIR-reflecting properties of different black pigments.Chromaflo's findings are presented below and cover the following areas:

- Reflection curves of different black colorants;

- Heat build-up profiles of different black colorants;

- TSR for different shades (light-dark) formulated using different black colorants;

- Relationship between TSR and surface temperature;

-

Contamination of NIR black pigments with organic black pigments;

- Effect of carbon black on TSR value in a white paint;

- Effect of carbon black on TSR value in a colorant based on NIR reflective black.

Reflection Curves of Different Black Colorants

Figure 4 shows the reflection curves (solar spectrum AM 1.5 according to ASTM G 159-98) of the black pigmented colorants at adjusted lightness (L) value (1/3 reduction, 160 µm dry layer thickness in a semigloss coating applied on black-white cards).

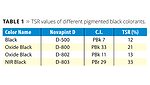

Focusing on the NIR range (700-2500 nm), a colorant containing carbon black pigment (PBk 7) shows the lowest reflection, followed by a colorant containing PBk 11 and PBk 33 pigments. Compared to the traditional black colorants, a considerably higher reflectance in the NIR region of the solar irradiance is achieved by the Novapint D-803 NIR-reflective colorant containing the functional NIR-reflective pigment PBr 29. From these reflection curves, the TSR value can be calculated (Table 1).

TSR for Different Black Shades

Table 1 indicates a significant difference in TSR values for the different black pigments. The difference in TSR value between the PBk 7 and PBr 29 is 21% in these dark shades. However, is this difference equally large in medium and light shades as well? To check this, we measured the TSR value of the four black pigments in three NCS shades (light, medium and dark).

Figure 5 shows the effect of replacing the PBk 7 and PBk 11 pigments (traditionally used in tinting systems) with PBk 33 and PBr 29 pigments in the three NCS S shades (2000-N, 4000-N and 7000-N). The test results lead to the conclusion that the replacement of traditional black colorants with an NIR-reflective black colorant (D-803) in a tinting system is beneficial for the TSR, even in light grey shades.

Temperature Profiles of Different Black Colorants

In the heat build-up test, the surface temperature of a pigmented top coat was increased by exposure to a halogen lamp (1000 Watt) under defined conditions (distance from lamp to surface was 60 cm). This heat build-up test simulates the sun irradiance of a coating containing carbon black applied on an external substrate.

To better visualize the temperature effect of different black pigments in colorants, the dark grey color shade NCS-S 7000-N was matched in a clear coating. The increase in temperature was measured in relation to the duration of exposure. The heat build-up profiles are shown in Figure 6.

The coating containing the Novapint D-803 NIR-reflective colorant (PBr 29) has a much lower surface temperature, -11 °C (-52 °F), compared to a similar coating containing black pigments (PBk 7 and PBk 11) exposed to the same conditions. The advantage of reduced heat build-up can be correlated with decreased energy consumption. The benefit is also enhanced coating life and an expected positive impact on prevention of premature failure of the EIF system. As a consequence, using dark grey colors with lower LRV values (luminosity) is becoming a reality.

TSR Value and Surface Temperature Relationship

From the test results carried out to date, it can be concluded that a high TSR value results in a low surface temperature and a low TSR value results in a high surface temperature. This leads us to the question: Is there a relationship between TSR value and surface temperature? Figure 7 shows the relationship between the surface temperature and the TSR value of a colored NCS-S 7000 N coating formulated using different black pigments. The graph shows that a 10% TSR increase corresponds to a decrease of approximately 4 °C in surface temperature.

Influence of Paint on TSR

Depending on the market segment, different qualities and types of coating are available for façade applications resulting in different pigment volume concentration (PVC), solid content and filler amount. Frequently added to the paint, fillers can potentially reduce the resulting reflectance in the near infrared. It is also important to bear in mind that even small amounts of impurities can negatively affect the TSR of the coating.

Figure 8 shows the effect of different types and qualities of coating on the TSR value of NCS-S 7000N. Latex is the reference paint used for all tests described so far. The chosen acrylic is a high-quality paint in which the silicate has very high PVC.

Besides the quality and type of coating, the color strength (whiteness level) of a paint will also affect the TSR of a shade. For example, formulating an off-white shade (e.g., NCS-S 2000N) using a paint with a TiO2 content of 20% will require more colorant than a paint with only 15% TiO2 (difference in colorant use is approximately 25%).

Opacity

Although a coating film can be visually opaque (or hiding), this does not mean that it is NIR opaque as well. To test the theory described earlier in the Pigment Physics section of this article, a clear coat was tinted using PBr 29 until visual hiding at 50 µm dry film thickness (5% by weight PBr 29) was achieved. TSR was measured on white and black substrates. Layer thickness was increased until the TSR on both substrates was equal (NIR hiding).

Figure 9 shows the TSR at increasing layer thickness. With an addition of 5% by weight PBr 29 in a clear coat, a NIR hiding film is obtained at around 600 µm. Looking at the layer thickness of 50 µm, there is a difference of -15% TSR, resulting in a surface temperature reduction of around 6 °C when using a white substrate instead of a black substrate.

The difference between visual and NIR opacity makes it difficult to predict the TSR for a coating without knowing its application and use. A grey primer containing carbon black will cause a greater loss in TSR than a similar primer formulated using NIR black or a white primer.

Blending White and Black Pigments

Most grey shades are a mix of white and black pigments supplemented with other colored pigments. Figure 10 illustrates the impact on the TSR value as a result of blending white and black pigments. An addition of just 0.1% by weight pigment PBk 7 results in a decrease of the TSR value of almost 40% (corresponding to 16 °C increase in surface temperature).

Contamination of NIR-Reflective Black with Organic Black Pigments

One area of concern is contamination of the NIR-reflective black pigment PBr 29 with, for instance, a carbon black pigment PBk 7. Figure 11 shows the Novapint D-803 colorant (PBr 29) contaminated with pigment PBk 7. A contamination of just 1% results in a 10% decrease in TSR value corresponding to +4 °C surface temperature.

From this we can see that mills and handling equipment must be properly cleaned to ensure that cross-contamination does not occur and that using even small amounts of non NIR-reflecting colorants to shade a batch can have drastic effects on TSR.

Conclusion

This article has demonstrated and described the process behind solar-reflective colorants. Several factors that can affect the colorant’s IR reflectivity such as individual pigment selection and mixing NIR-reflective pigments have been illustrated to gain a better understanding of the physics involved.

Using reflection curve measurements and the resulting TSR values of the colorants, the best possible solar-reflective colorant selection can be made. Choosing the right pigment selection, together with the Chromaflo Novapint D-803, will result in an optimal solar reflective colorant system.

Since the TSR covers the entire range of radiation between UV and NIR, black pigments show systematically lower TSR values compared to, for example, white pigments. For this reason, it is important to ensure that only TSR values of similar pigments are compared.

The outcome is clearly defined; using solar-reflective colorants will result in many benefits such as cooler surfaces, lower energy consumption and longer durability of materials, to only summarize a few. We have entered a new era of developing solar-reflective colorants.

For more information, visit www.chromaflo.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!