New Technology Helps Automotive Companies Build More Eco-Friendly Paint Shops

Dürr completes environmentally friendly paint shop

Or read the article in our August Digital Edition.

The world’s most environmentally friendly automotive paint shop: that was the requirement of BMW Brilliance when placing the order with Dürr in 2011 for the construction of the paint shop in Shenyang, China. This year Dürr has already received a follow-up order from BMW Brilliance to increase production capacity.

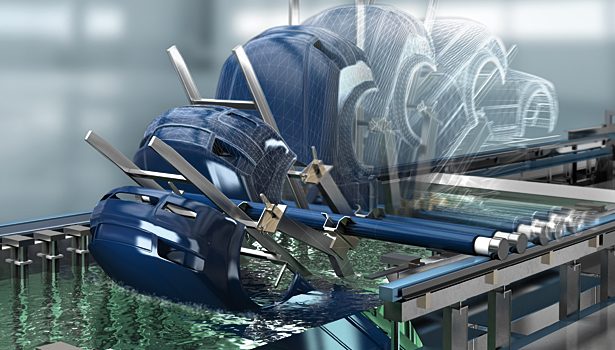

The extension of the installation to the full nominal capacity improves the already low energy consumption of the system to achieve the optimum value of less than 500 kWh per vehicle. This is barely a third of what was common 10 years ago. The energy saving measures of Dürr and BMW are effective already in the pretreatment and electro-coating area, where RoDip M rotational dip coating is used. This coating reduces the bath volume, thereby reducing energy and chemical consumption.

The new, second painting line also uses the fully automated Integrated Paint Process, which eliminates the need for primer and thus a drying phase. The spray booths are equipped with the EcoDryScrubber, a dry separation system for overspray offered by Dürr. This technology requires no water or chemicals. Recirculation of the process air results in 60 percent energy savings in the spray booth. Sixty five painting lines around the world already use or are currently being equipped with the EcoDryScrubber.

As is the case with the first line, the paint is applied using 32 Dürr EcoRP E033 and EcoRP L133 painting robots. The compact design of the new-generation EcoBell3 atomizer enables painting both the exterior as well as the interior with a single rotating atomizer.

The other already-installed technologies enabling environmentally friendly, sustainable automotive painting will be adapted to the higher production capacity. These include heat recovery from the supply and exhaust air streams as well as the recovery of waste heat from the ovens with the help of waste heat boilers. As a further environmental protection measure, the exhaust air from the clear coat booth is purified before leaving the plant.

Dürr is also helping General Motors reduce energy consumption and lower emissions at the new Eco+Paintshop for Shanghai General Motors (SGM). With a current throughput of 20 bodies per hour, the new design is so innovative that the paint shop can be extended to double capacity at any time. As of June 2015, Cadillac’s premium vehicles will be painted in Shanghai.

For both the interior as well as the exterior coating, SGM uses fully automated paint application, from the primer to the base coat through to the clear coat, thereby reducing paint consumption. The primer application is performed by 20 EcoRP L133 and L030 EcoRP painting robots. Forty four paint robots in stop-and-go operation apply base and clear coats. All robots are equipped with the EcoBell2 paint atomizer. The SGM paint shop also incorporates the EcoDryScrubber, allowing for 60 percent less energy consumption in the spray booth.

Heat recovery from the spray booth exhaust air and the oven’s exhaust air streams is an important aspect in the overall energy efficiency of the paint shop. Dürr's optimized hall ventilation concept, which is included in the delivery scope, also has a positive effect on this process. During the entire coating process, exhaust air from the spray booth is first pre-concentrated and then purified of all solvents in a RTO (regenerative thermal oxidation) process.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!