Self-Crosslinking Acrylic and Acrylic/Polyurethane Resins

for Waterborne Wood Finishes

FIGURE 1. Clear topcoats WB-3 and WB-4 (ROSHIELD 4000) applied over a solventborne, formaldehyde-releasing alkyd/urea conversion varnish.

One of the key factors driving innovation within the coatings market is reducing the environmental impact of a coating system. The pressure for improved environmental profiles is derived from governmental regulations and consumer concerns. For industrial wood coatings, the reduction of HAPs, VOCs and hazardous chemical species such as formaldehyde has driven reformulation efforts, as well as the use of new technologies such as UV-curable and waterborne coatings. Currently, the dominant technologies used in North America are solventborne nitrocellulose for wood furniture and acid-catalyzed alkyd-aminoplast conversion varnishes for kitchen and bath cabinets.1 Reformulation of these solventborne coatings to lower VOC and HAP emission levels has allowed their continued use in those markets, but the use of even lower VOC technologies should be expected to grow in the future.

Several types of waterborne acrylic technologies are being successfully used in the wood coatings market, including thermoplastic and self-crosslinking acrylics. When high performance, such as excellent chemical and solvent resistance, is needed in a one-component coating, the self-crosslinking acrylics are preferred. This article describes a new self-crosslinking waterborne acrylic resin, ROSHIELD™ 4000, designed for use in wood coating applications, and compares its performance with some current waterborne acrylic resins and conventional solventborne systems.2 Specifically, results are reported for testing in wood furniture and kitchen cabinet applications. The performance of the new ambient temperature self-crosslinking waterborne acrylic binder is highlighted, demonstrating that it can be formulated into wood finishes that are one-component, high performance and low VOC. A key feature of this new self-crosslinking technology is that it does not yellow over formaldehyde-containing substrates and basecoats, which allows for its use over a broader range of wood applications than current self-crosslinking acrylic resins. ROSHIELD 4000 acrylic resin facilitates coatings with excellent durability, chemical resistance and surface properties such as block and print resistance and hardness, all of which are important features for factory-finished wood products.

In addition, when the acrylic is blended with a specially designed polyurethane dispersion (PUD), a further enhancement to hardness development occurs due to the accelerated release of coalescing solvents. The faster hardness development translates to improved block and print resistance, even while formulating at a reduced VOC. Comparison of the new acrylic and acrylic/PUD binders with each other and current waterborne and solventborne wood coating systems are detailed.

Experimental

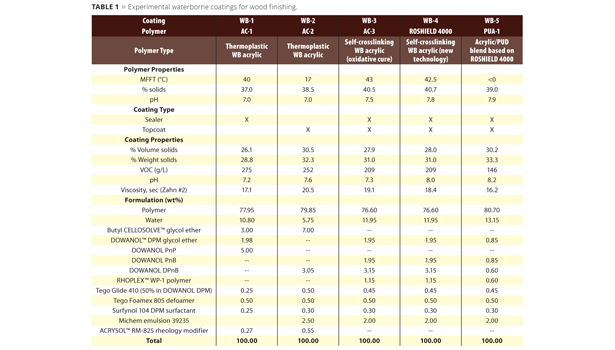

Experimental waterborne acrylic clear formulations were compared to commercial coating formulations in a variety of tests to evaluate the coatings for wood furniture and cabinets. The experimental waterborne coatings are described in Table 1 (See Slideshow for all tables); each coating is based on a different acrylic latex polymer. Coatings WB-1 and WB-2 are based on one-component thermoplastic acrylic binders designed for use as sealers and topcoats in general wood applications. The polymers in WB-1 and WB-2 do not undergo crosslinking after film formation, and thus resistance properties rely on their initially high molecular weight. WB-3 is based on a currently available one-component, ambient temperature self-crosslinking acrylic binder (AC-3). The self-crosslinking functionality in AC-3 relies on an oxidative curing mechanism, and is known to lead to yellowing when used over substrates or coatings that release formaldehyde. WB-4 is based on a newly developed one-component, ambient temperature self-crosslinking polymer, ROSHIELD 4000, which offers faster post-film formation crosslinking and no yellowing when formaldehyde is present. It is designed to be self-sealing and, therefore, can be used as both a sealer and topcoat in various wood coating applications.

ROSHIELD 4000 acrylic resin was also blended with a soft aliphatic polyester polyurethane dispersion to form an acrylic/PUD blend designated as PUA-1 and used in the formulation of coating WB-5. It has been previously reported that blending acrylics with the unique PUD used here allows faster release of coalescing solvents from the drying film.3 The blend offers a balance of properties such as lower VOC, good film formation and improved hardness properties.

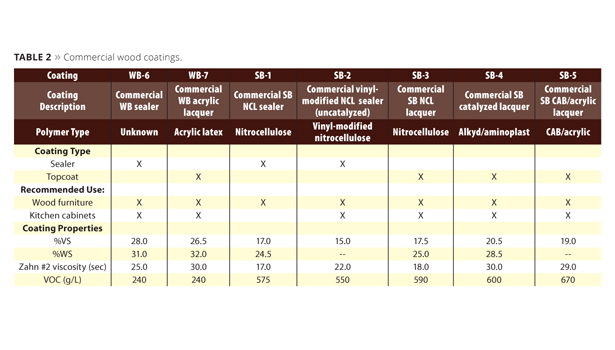

The experimental systems were compared to commercially available systems that are designed for use in wood furniture and cabinet applications. The commercial coatings are described in Table 2. Commercial waterborne coatings were obtained in both sealer (WB-6) and topcoat (WB-7) formulations. The binder chemistry of WB-6 is assumed to be acrylic latex, although it is not stated explicitly in the product literature. Solventborne sealers include SB-1, based on nitrocellulose and formulated to a lower VOC than traditional nitrocellulose sealers, and SB-2, based on a vinyl-modified nitrocellulose system that can be used with or without a catalyst. The solventborne topcoats include a nitrocellulose lacquer (SB-3), an alkyd/aminoplast acid-catalyzed conversion lacquer (SB-4) and a CAB (cellulose acetate butyrate)/acrylic lacquer (SB-5). The sealer and topcoat combinations were chosen based on the manufacturer’s system recommendations.

Panel Preparation

For most tests the coatings were applied to maple panels (4 in. x 12 in.) by conventional air spray at approximately 1.0 mil (25 mm) dry film thickness per coat, with one coat of sealer and two coats of topcoat. Maple panels were sanded with 220-grit sandpaper prior to use; sanding dust was removed with a clean, lint-free cloth. Each application coat was dried at room temperature for 2 h. The sealer was sanded with 280-grit sandpaper prior to application of the topcoat. After sealer and topcoats were applied, the maple panels were placed in a constant temperature and humidity room (75 °F and 50% RH) for 2 weeks prior to testing.

For a few tests where the topcoat itself was being evaluated (hardness, block and print resistance), the topcoats were applied by drawdown bar to a treated aluminum panel (Q Panel Type AL-412 chromate pretreated aluminum, 4 in. x 12 in.) to yield approximately 1.5 mil (38 mm) dry film thickness. Panels were placed in a constant temperature and humidity room (75 °F and 50% RH) for the specified amount of time listed prior to testing.

Testing Procedures

Coatings were evaluated according to the test methods for kitchen and vanity cabinet coatings outlined in the KCMA standard.4

- Detergent and Water Resistance (edge soak): For this test, all six sides of the maple panels were coated as described above. A #8 cellulose sponge was soaked in a 0.5% Palmolive dish detergent solution, and the panel edge was placed on the sponge for 24 h. Panels were rated for delamination, swelling, color change, checking and other forms of film failure. A pass is reported for no change in the appearances of the film and panel.

- Hot and Cold Check Resistance: Coated maple panels were cycled between hot (49 °C), ambient (25 °C) and cold (-21 °C) temperatures, and were run as described in the KCMA standard using a Thermotron environmental chamber model S-8S-SL. A pass is reported for no change in the panel or coating.

- Shrinkage and Heat Resistance: Coated maples panels were tested at 49 °C and 70% relative humidity for 24 h using a Hotpack environmental chamber model 417532. A pass is reported for no change in the condition of the coating.

- Chemical Resistance: The coating was subjected to a variety of household chemicals to determine resistance to staining and discoloration. The chemicals include lemon, orange and grape juices, vinegar, ketchup, coffee, olive oil, 50% ethanol, 0.5% Palmolive dish detergent, and mustard. Chemicals were applied to the coated maple panel in a vertical position, and allowed to stand for 24 h before cleaning and rating of the panel. In the case of mustard, cleaning was performed after a 1 h exposure. The exposed coating was evaluated for discoloration, staining and other obvious changes, and rated on a 1 to 10 scale, with 10 equal to no change. Other tests were run on maple substrates to evaluate use of the coating systems for wood furniture and general wood coatings. These include the following:

- Clarity: A visual observation of the coating clarity.

- Mar resistance: A wooden tongue depressor was rubbed over the coating in a back and forth motion. Marring of the finish was rated on a 1 to 10 scale, with 10 being no marring and 1 being very heavy.

- Adhesion: A crosshatch scribe was cut into the coating, resulting in 100 squares. Adhesion was tested by the tape pull method of ASTM 3359 using Permacel 99 tape. Ratings use a scale of 0B to 5B, with 5B being no adhesion loss.

- Chemical Spot Resistance: Resistance to common chemicals was evaluated by applying spots of the chemical to the coated panel for a specified time, then cleaning the panel with clean water and a sponge, and drying prior to rating. Chemicals were applied to the horizontal surface by saturating a 2.3 cm grade 3 Whatman filter and covering with a watchglass to prevent evaporation. One-hour spot tests were done using ethanol, isopropyl alcohol, butyl acetate and acetone. Overnight exposures for 16 h were done with water, hot coffee, 50% ethanol, Formula 409 cleaner, isopropyl alcohol, 7% ammonia, Scheaffer brand red ink and grape juice. Film damage and discoloration/staining are rated on a scale of 1 to 10, with 10 being no change.

Several tests were performed on just the topcoat, including hardness, block and print resistance and gloss and color retention. These tests were evaluated for topcoats applied to treated aluminum panels.

- König Hardness: Measurements were taken at various intervals over the course of 3 weeks and evaluated according to ASTM D4366 using a TQC SP0500 Pendulum Hardness Tester, and reported in seconds.

- Pencil Hardness: Measurements were taken at various intervals over the course of 3 weeks and evaluated according to ASTM D3363, and reported as the highest pencil that did not gouge the coating.

- Block Resistance: Panels were dried for 7 days, and then two 1.5-inch-wide strips were cut from the aluminum panel and placed face-to-face forming a cross. A #8 rubber stopper was placed on the cross-section of the strips, and a 1 kg weight placed on top of the rubber stopper. Block resistance was rated for two conditions, (1) after 30 min at 60 °C, and (2) after 16 h at room temperature. The following 0 to 10 scale was used to rate the coatings for tack and film damage: 10, no tack/perfect; 9, trace tack/excellent; 8, slight tack/very good; 7, slight tack/good; 6, moderate tack/good; 5, moderate tack/fair; 4, severe tack, no seal/fair; 3, 5-25% seal/poor; 2, 25-50% seal/poor; 1, 50-75% seal/poor; 0, complete seal/very poor.

- Print Resistance: Panels were dried for 7 days, and then a 1.5 in. x 1.5 in. square was cut from the aluminum panel. A piece of cheesecloth was placed over the square, a #8 rubber stopper was placed on the cheesecloth, and a 1 kg weight placed on top of the rubber stopper. Print resistance was rated for two conditions, (1) after 30 min at 60 °C, and (2) after 16 h at room temperature. The following 0 to 10 scale was used to rate the coatings for print and film damage: 10, perfect/none; 9, excellent/trace; 8, very good/very slight; 7, good-very good/slight-very slight; 6, good/slight; 5, fair-good/moderate-slight; 4, fair/moderate; 3, poor-fair/considerable-moderate; 2, poor/considerable; 1, very poor/severe; 0, complete failure.

- Gloss and Color Retention: Topcoats were applied in one coat at approximately 1.5 mil dry film thickness to the white portion of a metal Leneta chart T12-10. Panels were dried for 1 week prior to testing. Panels (3 in. x 5 in.) were exposed in a QUV accelerated weathering cabinet using UV-A bulbs (340 nm) and a cycle consisting of 8 h light and 4 h condensation. Gloss (20°/60°) and color (L*a*b*) were measured initially and at various time intervals during the exposure.

Results and Discussion

The experimental clear waterborne coating systems evaluated in this study for use in furniture and cabinet applications include a sealer/topcoat combination based on two thermoplastic acrylic polymers (EXP-A), and a self-sealing system based on sealer/topcoats of a currently available self-crosslinking acrylic (EXP-B). The properties of these current systems are compared to ROSHIELD 4000 acrylic resin in a self-sealing system designated as EXP-C. The thermoplastic acrylic polymers used in EXP-A are designed for use in general wood applications, including wood furniture and kitchen cabinets, but lack in some chemical and stain resistance properties due to the fact that the polymer does not crosslink after film formation. For a simple thermoplastic acrylic such as those used in sealer WB-1 and topcoat WB-2, properties such as chemical and solvent resistance and durability are primarily due to the initial high molecular weight of the polymer and the eventual chain entanglement that occurs during latex film formation. Crosslinking of a latex polymer after film formation is an effective method to improve on these properties.

The new self-crosslinking acrylic binder ROSHIELD 4000, used in the sealer/topcoat WB-4 of system EXP-C, uses a proprietary crosslinking technology that offers rapid crosslinking after film formation, and prevents crosslinking beforehand in the wet state. This leads to rapid property development, expected to be complete within a few days, while maintaining excellent film formation before crosslinking occurs. In comparison, the self-crosslinking technology used in sealer/topcoat WB-3 of system EXP-B is relatively slow, occurring by an oxidative curing mechanism that develops over several weeks of cure time. Another important feature of ROSHIELD 4000 is that it will not yellow over formaldehyde-containing substrates and basecoats, and this benefit is illustrated in Figure 1. The clear formulations WB-3 and WB-4 were applied over a basecoat (sealer) based on a solventborne acid-catalyzed alkyd/urea system. As depicted in Figure 1, the clear topcoat based on WB-3 has yellowed where it is in contact with the formaldehyde-containing sealer, whereas the topcoat based on WB-4 has not yellowed. This non-yellowing benefit allows the use of ROSHIELD 4000 acrylic resin in a broader range of wood coatings applications, including over basecoats that release formaldehyde such as conversion varnishes, and over engineered wood substrates that may release formaldehyde due to adhesives, such as medium density fiberboard (MDF).

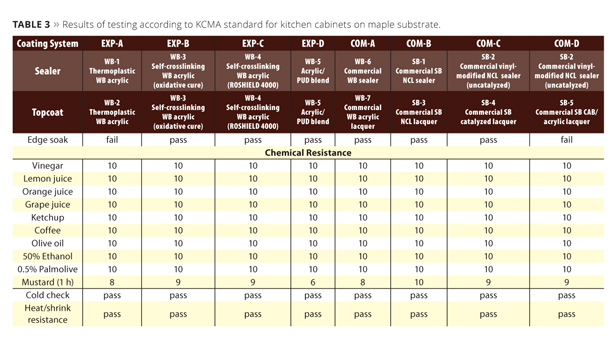

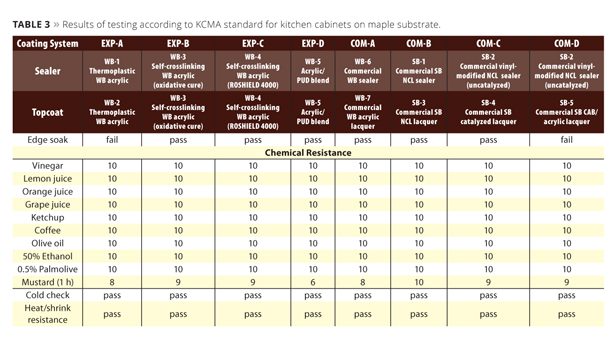

The comparison of the waterborne thermoplastic and self-crosslinking acrylic systems with several commercial systems using test methods designed for kitchen cabinet coatings by the Kitchen Cabinet Manufacturers Association (KCMA)4 is given in Table 3. Three of the four commercial systems tested were recommended by their manufacturers for use on kitchen cabinets. These include the waterborne system (COM-A), the system utilizing a solventborne conversion lacquer topcoat (COM-C) and COM-D which uses a solventborne CAB/acrylic topcoat. The fourth commercial system, COM-B, is based on a solventborne nitrocellulose sealer and topcoat, and is not recommended for kitchen cabinets, even though it performed fairly well in our testing. In the KCMA standard evaluations, the systems performed well in the majority of tests. All passed the edge soak test, where the panel edge is soaked in an aqueous detergent solution, except for COM-D (CAB/Acrylic), which exhibited slight cracking and whitening. All systems passed the Shrinkage and Heat Resistance test, as well as the Hot and Cold Check Resistance test, with no evidence of film failure. The waterborne systems performed very well in the chemical resistance tests, with the exception of their exposure to mustard, which left moderate staining on the films. The solventborne systems did slightly better for mustard resistance, but also showed slight staining. Overall, the waterborne systems performed well in KCMA testing compared to the solventborne systems.

A similar comparison is given in Table 4 using test methods suitable for wood furniture and general wood coating applications. All of the systems had good clarity when sprayed on maple panels. Gloss values were in most cases lower for the spray application over maple than for drawdowns on a smooth surface, but the waterborne systems had good gloss compared to the solventborne systems, with the highest gloss observed for the waterborne acrylic/PUD system EXP-D. Adhesion was excellent for all of the systems, with no failures observed. All of the commercial solventborne systems had very poor mar resistance, perhaps evidence of the impact that formulation additives can have on the final properties of the coating. The waterborne experimental coatings were formulated with a silicone mar additive. Although there is a difference in mar resistance of the various systems, Table 5 shows that the hardness of all topcoats is fairly similar after 2 weeks dry time. The solventborne systems even have an edge in hardness over the waterborne systems as measured by both Kӧnig and pencil hardness. For the waterborne topcoats, the acrylic/PUD coating WB-5 shows a clear advantage of faster hardness development, as detailed in Table 5 and shown in Figure 2, which plots Kӧnig hardness over time. Compared to WB-4, which is based on ROSHIELD 4000, the hardness development of WB-5 is greatly accelerated. ROSHIELD 4000 is the acrylic component of acrylic/PUD coating WB-5. The faster hardness development is a result of faster coalescent release from the film, and caused by the ability of the coalescent to diffuse out of the coatings more quickly via the soft polyurethane polymer phase than through the acrylic phase. Evidence for the proposed mechanism has been previously described in greater detail elsewhere.3

The results of the chemical spot tests (Table 4) demonstrate an advantage for the new self-crosslinking acrylic binder. System EXP-C (based on ROSHIELD 4000) is observed to provide excellent resistance to several solvents, including ethanol, isopropanol, butyl acetate and acetone, after 1 h exposure. In general, the other systems performed poorly in the 1 h spot tests with these chemicals. Comparing EXP-A and EXP-C, it is clear that the self-crosslinking mechanism in ROSHIELD 4000 (EXP-C) has provided good crosslinking after the one week dry time, building polymer molecular weight and providing better resistance to solvents. The good chemical resistance of ROSHIELD 4000 is also evident in the 16 h spot tests with the other reagents. The chemical resistance of ROSHIELD 4000 is also better than EXP-B, demonstrating the higher performance of the new self-crosslinking technology compared to the oxidative curing mechanism utilized in EXP-B. Excellent chemical resistance in waterborne wood finishes has previously been achieved in two-component waterborne polyurethane coatings, where crosslinking a waterborne polyol with a water-dispersible polyisocyanate provides high crosslink density.5 With the new self-crosslinking acrylic described here, excellent properties are being obtained in a one-component system, which is an important factor in the ease of use of a coating.

Block and print resistance of the clear topcoats are described in Table 5. Topcoats WB-4 and WB-5, based on the acrylic and acrylic/PUD polymers containing the new self-crosslinking technology, display the best block and print resistance for the waterborne coatings. The block and print resistance of the topcoat WB-4, based on ROSHIELD 4000, particularly at elevated temperatures, is equivalent to the harder solventborne coatings used in this study. Only the acid-catalyzed conversion varnish (SB-4) is slightly better for hot print resistance. Block and print resistance are important properties for an industrial wood coating, with block resistance as a key property during the manufacture and stacking of finished pieces, and print resistance as a key property for instances where objects are put on the surface of a piece of coated wood once it is placed into service, such as on furniture.

Table 6 shows a comparison of the gloss and color retention of the various topcoats used in this study. For this test, the clear topcoats were applied to a metal panel coated with a white finish, in order to visually observe any yellowing that might occur during exposure to UV light. All of the topcoats containing waterborne and solventborne acrylic polymers performed well for both gloss and color retention. The nitrocellulose lacquer (SB-3) and the alkyd/aminoplast conversion lacquer (SB-4) both had significant yellowing after only a few days exposure. In contrast, the acrylic systems maintained their gloss and color even after more than 600 h. Given the well-known UV stability of acrylic polymers, this is perhaps not too surprising, and demonstrates a main benefit of acrylic wood finishes.

Conclusions

This study demonstrates that a waterborne acrylic coating system designed for finishing wood products can perform well compared to traditional solventborne finishes. The commercial waterborne system (COM-A) evaluated in this study illustrates that waterborne systems with good performance already exist in the marketplace. Development of the new self-crosslinking acrylic polymer ROSHIELD 4000 offers formulators the possibility of extending the performance of waterborne systems to even higher levels. In particular, rapid crosslinking provides excellent chemical and solvent resistance properties, which are very important in both the wood furniture and the kitchen and bath cabinet industries. Furthermore, this technology, when combined with a unique PUD, facilitates good film formation at an even lower VOC level, and excellent surface properties such as hardness, block resistance and print resistance. The UV stability of the acrylic backbone, along with the ambient temperature self-crosslinking mechanism, offers excellent gloss and color retention compared to the traditional solventborne technologies. In addition, ROSHIELD 4000 will not interact with formaldehyde released from either the substrate or another coating layer, and will not display yellowing of the film, which can be an issue with some current self-crosslinking acrylics. Combined with proper formulating technique, ROSHIELD 4000 acrylic resin offers the wood finishing industry a one-component, low-VOC and high-performance alternative to traditional solventborne systems.

References

- “U.S. Paint & Coatings Market Analysis (2004 – 2009)”, National Paint and Coatings Association, October 2005.

- ™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow.

- a) Fu, Z.; Hejl, A.; Swartz, A. Designed Diffusion Technology: A Paradigm Shift in Film Formation. Eur. Coat. J.2009, 6, 26-33. b) Procopio, L.; Vielhauer, L.; Greyson, E. Novel Hybrid Technology Accelerates VOC Release from Wood Coatings. PCI Magazine 2011, May, 48-62. c) Procopio, L.; Vielhauer, L.; Greyson, E.; Hejl, A. Designing Latex Morphology to Optimize Wood Coating Performance. CoatingsTech 2012, February, 32-41.

- ANS/KCMA A161.1-2000, Performance and Construction Standard for Kitchen and Vanity Cabinets, Kitchen Cabinet Manufacturers Association, 2001.

- a) Renk, C.A.; Swartz, A. J. Proc. 23rd Waterborne, High Solids and Powder Coatings Symposium, New Orleans, LA, 1995. b) Xudong Feng, S.; Dvorchak, M.; Hudson, K.E.; Renk, C.; Morgan, T.; Stanislawczyk, V.; Shuster, F.; Todd, D.; Bender,H.; Papenfuss, J. New High Performance Two-Component Wood Coatings Comprised of a Hydroxy Functional Acrylic Emulsion and a Water-Dispersible Polyisocyanate. J. Coat. Technol. 1999, 71(899), 57.

This article is based on a paper that was presented at the American Coatings Show, May 2012, in Indianapolis.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!