Silicone-Based Technology for Decorative Paints

Their Contribution to Sustainability

There are multiple drivers for innovation in the decorative coating industry, – cost, VOC legislation and the desire for more eco-friendly products to name but a few – but perhaps none earns more attention than sustainability. At the Paint Research Association’s 8th International Wood Coatings Congress, October 2012, in Europe, sustainability (increasing the lifetime of coatings and reducing the amount of finite raw materials used), and the part the coatings industry has played in driving efforts in this area, were the focus of discussion.

In the coatings market, silicone additives are well known for the surface properties they bring to the coatings formulator – slip, abrasion resistance, wetting, leveling and defoaming. Perhaps what is less known is the contribution these materials can make to improve the sustainability of decorative coatings, for both architectural and wood coating applications. Improvements to increase the longevity of coatings and the ability to use fewer natural resources, such as titanium dioxide, are characteristics that Si-based materials can deliver today or in the near future. In this article we investigate how silicones deliver these properties.

Weather Resistance

Improvements in weather resistance can be achieved in a number of different ways using silicones. For example, resistance to binder degradation with UV exposure (chalking), water resistance and anti-efflorescence are all ways the longevity of a decorative coating can be increased. In decorative applications this longevity is also demanded by building owners and specifiers without a significant increase in cost. Silicones offer cost-effective solutions to the market, since they can be added to the formulation at additive addition levels.

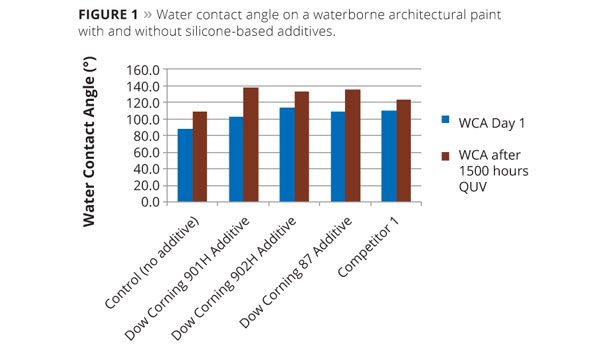

An example of this can be seen with the family of silicone-based water-resistant additives shown in Figure 1. In this example, the additives have been added to a waterborne acrylic architectural paint at 2% actives to the total formulation; the water contact angle (WCA) on the surface of the coating when dried was evaluated on day 1 and after 1500 h QUV A testing. The three silicone-based additives from Dow Corning show improved water beading compared to the control (no additive) on day 1 and after QUV weathering.

The reason for the increase in WCA from day 1 to 1500 h QUV A, even for the control with no additive, is not proven, but we can hypothesize that this is due to binder degradation and subsequent removal of any hydrophilic components (surfactants) during the spraying cycle of the QUV test. What’s important to note is that the higher WCA with the silicone additives is maintained even after QUV weathering. Also important to know is that the surfaces remained recoatable after weathering.

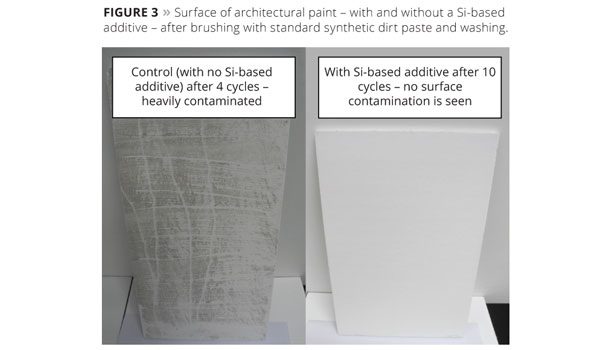

While water beading can indicate water resistance, in some cases this is simply an attribute designed to lead the consumer to this conclusion. Often it does not reflect the true water repellency of the decorative coating, and achieving both properties with the same additive can be difficult. It is, therefore, important to consider water repellency as a separate performance criteria alongside WCA. Figure 2 shows the water repellency and the WCA of an acrylic emulsion-based exterior trim paint.

In this wood coating we can see that the water repellency (shown as water uptake, where the lower the number = better performance) is improved with Dow Corning® 87 additive at only 1% active silicone content. Perhaps more surprising is that the WCA also improved with this additive, which is not the case for the other materials tested, even at higher addition levels.

Efflorescence is the formation of salt deposits on or near the surface of mortar or concrete (cement), causing a change in the surface appearance. Silicones can also be used to formulate primer paints for treatment of mortar and concrete (cement) to prevent efflorescence.

Better Dispersion to Reduce TiO2 Content

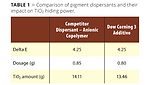

In addition to improving the physical properties of coatings, leading to more durable coatings and therefore improved sustainability, the reduction in the use of natural resources within the formulations also has a huge potential impact. While silanes are known for pigment and filler dispersion, silicones are not. Non-silicone products for this benefit are typically organic dispersants such as polycarboxylic acid polymers or polyurethane polymers. While these organic dispersants can deliver good performance, the right silicone can deliver the same properties (viscosity stability and fineness of grind, anti-flooding and floating) but also offer improvement in hiding power by comparison. This means expensive titanium dioxide levels can be reduced in the coatings to achieve the same hiding power as that seen with traditional organic dispersants.

Table 1 compares the performance of Dow Corning 3 additive versus a non-silicone competitor dispersant (an anionic co-polymer) in a solventborne, glossy white, wood coating. Additives were added during the pigment grind stage. To achieve the same hiding power (delta E), the level of titanium dioxide used was adjusted. A 4.6% reduction in the amount of titanium dioxide required to achieve the same degree of hiding was found when the silicone additive was used in place of the traditional organic dispersant.

New developments in silicone technology also promise to deliver much more in the future. Improvements in self-cleaning performance of exterior applications, for example, could reduce costly cleaning or re-painting activities as well as having an environmental impact by reducing the amount of solvents or surfactants used during cleaning procedures or in paint manufacture. In Figure 3, panels coated with a middle PVC flat paint were tested for dirt-pick-up/easy clean. In this method, the panels were brushed with a standard synthetic dirt paste, allowed to dry for 2 h and then washed for 1 min – this counts as one cycle. The procedure was then repeated.

Better anti-stain performance for interior applications would benefit the end consumer and the environment. In Figure 4 we see the performance of a styrene acrylic-based architectural paint when subjected to waterborne red ink marker pen. The control with no silicone clearly shows some staining after cleaning the surface with a water-soaked sponge (10 wet rubs), while the paint containing a silicone additive shows a much cleaner surface after the same treatment.

Conclusions

Silicones offer the decorative coating formulator multiple ways to improve the sustainability of their products, and promise to deliver even greater performance in the near future. Sustainability improvement comes with the addition of silicones at additive levels to formulations, allowing them to achieve the performance benefits to maximize the coating’s life and protect the substrate while still controlling the cost of the total formulations.

For more information, visit www.dowcorning.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!