New Functionalized Particles

Solutions for Enhanced Performance, Efficiency and Sustainability

Today’s coatings market expects more from its white pigments than brightness and opacity. White pigments, such as titanium dioxide (TiO2), barium sulfate (BaSO4) and zinc sulphide, are just examples of many ingredients possible in a complex coatings formulation. As part of that formulation, concerns related to a wider array of performance requirements, process efficiencies and sustainability must be addressed.

In order to understand and follow the market demand in the context of sustainability, we must have a deep knowledge of the market’s value chains. This is essential to providing comprehensive solutions for the market. It is important to work closely with customers to examine each step of the value chain, its requirements and targets. This approach leads to product, application and process expertise, and provides the most efficient solution.

One example of this approach is the original equipment manufacturer (OEM) automotive paint shop. Process changes are driven by energy reduction and thinner coating layers. The reduction of the primer layer and termination of one drying oven leads to cost savings, but it also has an impact on performance. Each layer has its value - the task of the electrocoat (E-coat) is corrosion protection, the primer provides stone chip resistance, the basecoat imparts the color, and the clearcoat enhances appearance.

TiO2 and BaSO4 are part of this process, and can be used in the E-Coat, primer or basecoat. Sachtleben has developed a new technology of functionalized particles whereby the BaSO4 particles are epoxy- and amino-functionalized. The key to this technology is an increased coating network density via direct chemical bonding, which offers new formulation opportunities.

Increasing Efficiency

TiO2

Another example of efficiency improvement is the substitution of TiO2 with lithopone or BaSO4. This approach is well known in the industry and leads to cost savings. By incorporating functionalized BaSO4, the formulator now has the opportunity to reduce the resin content within the formulation, while maintaining a strong coating network via chemical bonding. These formulation paths offer cost-saving opportunities for the formulator without sacrificing performance.

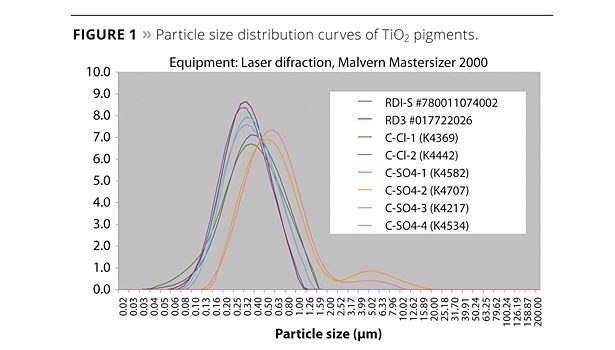

When using TiO2, choosing the right grade is the starting point for hiding power and a cost-efficient formulation. Hiding power determines the surface area that can be painted with a gallon of paint, and can be enhanced by using highly-efficient TiO2 technologies. Key for this property is the narrow particle size distribution (Figure 1).

It is also important for formulators to understand a specific property of anatase TiO2: its photocatalytic activity contributes to antibacterial sterilization, air cleaning and water cleaning. This technology will play a significant role in coatings applications as the awareness of our society goes toward green. (The German Federation for applied photocatalysis, founded last year, describes the capability of this technology at www.applied-photocatalysis.com.)

Sag Control

In paint formulating, it is well known that sag control agents can be a cost driver. One proposal is to utilize functionalized BaSO4 for its anti-sag properties. Figure 2 shows that non-functionalized BaSO4 is limited regarding anti-sagging properties. Figure 3 shows that functionalized BaSO4 particles can be utilized as cost-efficient anti-sagging additives in selected coating systems. In this example, you can see the improvement in coatings as thin as 100 µm in a urethane-modified alkyd system.

Haze, Gloss, Hardness and Other Properties

Another example of the potential of this technology is the benchmark in waterborne systems with 25 percent BaSO4 content. The functionalized particles lead to significant improvement in gloss and reduction in haze values. The slightly reduced pendulum hardness is an indicator of increased flexibility (Table 1).

A stable rheological pattern can be observed for functionalized BaSO4 in waterborne systems. Results show a stable viscosity at 40 °C up to 60 days at low shear rate. At high shear rate, we see a low viscosity of the system, which supports processability or manufacturing speed.

The next example of performance enhancement is the improvement in scratch resistance. Our studies showed that functionalized BaSO4 applied into in-mold coatings systems enhanced scratch resistance up to 37%.

Functionalized particles also can provide superior barrier properties. With functionalized particles, blanching in powder coatings systems can be eliminated. Superior barrier properties also contribute to anticorrosion properties.

It is not a surprise that the interaction between pigment and resin impacts viscosity of coating systems. In the plate flow test, we see that the pigment quantity impacts viscosity, but we see also that the viscosity can be controlled using the appropriate resin (Figure 4).

In order to evaluate the flexibility further, we observed the increase of the flexural modulus with functionalized BaSO4 in an epoxy-based composite. The flexural modulus could be enhanced with the functionalized particle.

Conclusion

New functionalized particles can improve the performance of high solids, powder, waterborne and UV coatings systems. They also provide a cost-efficient way to meet the requirements of these systems.

This technology, available in today’s new functionalized pigments, improves performance, efficiency and sustainability. The approaches described in this article provide formulators with a taste of the potential that this technology can provide in coatings systems and the challenging demands it can meet in the context of green coatings and sustainability. n

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!