Modern Wet Milling and Material Processing

Manufacturers are challenged to integrate a repeatable method of production that is capable of this level of size reduction while controlling labor and energy costs. The system must also be robust enough to handle the most abrasive raw materials.

Traditional Wet Milling

The coatings industry is no different from others in its search for modern manufacturing techniques. The traditional high-speed dissolver, ball mill, vertical mill and standard horizontal mill have been the primary methods used to mill pigmented materials for more than 50 years, and are still considered to be the industry standards throughout the world today.

Ball mills are generally batch units, which means that all ingredients are charged into the chamber and the mill is run unattended for a specified amount of time (or number of revolutions). The design of a typical ball mill only allows for about a 65% (of total capacity) fill of product, which allows room for the grinding media to rise and fall for impact.

Especially with smaller units, the labor and time required to batch and discharge the machine can become problematic and inefficient. Because of this inefficiency, a typical ball mill will only be available for grinding 75% of the time, which does not take into consideration both scheduled maintenance and emergency breakdowns.

Vertical mills are in use around the world, but they tend to be limited in media volume charge and have fluidizing issues related to the use of finer grinding media. The standard horizontal mill was introduced in the late 1970s and is more commonly used today, as it eliminated many of the inefficiencies with the older ball and vertical mill technologies.

Another challenge involves finer and finer particle size demands. Traditional ball mills and vertical mills are generally limited to a finished particle size of approximately 5 microns, which can be achieved only with great attention to media size.

Grinding media for ball mills ranges in size from 6 - 10 mm for most traditional applications and 1.5 - 2.0 mm for vertical mills. Typical ball mills use high-alumina or porcelain balls for their density, but wear is relatively high. Modern mono-size yttria-stabilized zirconium, zirconium oxide or cerium media is not a practical alternative due to the high cost per charge, as well as the frequent re-charge rate. Simply put, it is difficult for the traditional ball mill to put enough energy into the media charge to reduce particles to the sizes and distributions now required.

Media Selection

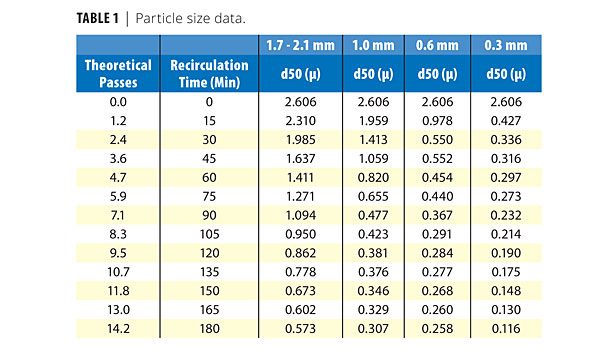

In all milling processes, the ultimate performance of the mill is highly dependent on the media size and distribution. Table 1 shows the effect of different media sizes on the number of cycles required.

Horizontal Media Mills

The standard horizontal media mill has been used in the ink and coatings industries for over 30 years. Best described as a high-energy continuous ball mill, the machine’s design has undergone continuous changes since its introduction to keep up with the demands for finer particle sizes and narrower particle distributions.

The horizontal media mill has a closed chamber that receives the pumped premixed slurry in one end and discharges the milled product from the opposite end. The mill utilizes a mechanically sealed shaft that is cantilevered from a heavy bearing housing. This shaft can be fitted with a wide variety of agitators, including discs, pegs or disc/pin combinations, depending on the particular process. The chamber is typically charged with grinding media to 60-90% of the net shell volume. The high energy imparted by the agitators on the grinding beads creates frictional heat, which is removed by chilled water circulating in the cooling jacket of the chamber.

As the milling shaft rotates, the media is fluidized by the agitators positioned on the shaft. The peripheral agitator speed for this type of mill is typically 8-17 m/sec. The pigmented dispersion slurry passes through the length of the chamber under pump pressure while being milled through media-particle impact and shear, as well as particle-particle impact and shear. At the exit end of the chamber, media is retained in the mill by a screen (also called a separator or filter) that is of such size that slurry particles can pass through. It is important to note that the screen plays no role in particle size distribution.

Benefits

Determined by product type, particle size and distribution, these milling systems are unique to each specific application so design and setup are crucial for success. Equipment manufacturers must be able to supply the latest in wear-resistant materials, agitator design and media separation as part of a successful installation. Selection of the proper construction materials is based on factors such as vehicle system, product end use and the abrasive nature of the raw materials. Materials of construction for milling wearing parts might include various types of ceramics, urethane and urethane-coated, high-polymer plastics, work hardening alloys and composites.

These milling systems are highly versatile and can be configured for one- or multi-pass operation through outfitting with the proper tanks and pumps. In addition, duplex systems with dual milling heads on a common frame combine the best of both by passing through a second chamber on the same machine that can be charged with media of a different size than the first chamber. Duplex milling (sometimes referred to as “cascading”) offers the advantage of operating two grinding chambers with one control system in a reduced footprint compared to two mills. When nano-sized particles are specified, such as those required in automotive paints, stains, ceramic inks and printing inks, the mills are typically setup in high-flow recirculation.

With the onset of nanotechnology and finer particle size distributions, the new high-energy horizontal mill is an efficient means for coatings producers to effectively produce finer dispersions with less energy, low maintenance costs and higher productivity results.

System Integration

In today’s competitive environment, it’s not just about selecting the right wet grinding mill − integration to the overall system is important as well. Whereas a ball mill installation is fairly straightforward and uncomplicated, the successful installation of a high-energy horizontal mill requires careful consideration of a number of factors:

• Premix equipment selection for slurry preparation;

• Properly sized chiller system to remove BTU energy from the grinding process;

• Pump systems sized for optimum flow and resistance to abrasive materials;

• Feed and receiving tanks equipped with mixers for adequate suspension and batch turnover;

• Process plumbing designed to minimize waste and to optimize product yield;

• Controls and instrumentation packages are crucial for process control and automation, as well as data acquisition and product repeatability;

• If post milling filtration is required, selection of filter system is crucial to upstream mill efficiency; and

• Moving materials to and away from milling system in the most efficient manner possible.

High-energy media (horizontal) mills are commonly used in the manufacture of coatings, inks, agricultural, nutraceuticals and pharmaceuticals, electronics, ceramics and many other fine-particle products. As material processing innovations require finer and finer particle sizes, the use of these systems will grow, especially where high strength gains through the use of nano-sized materials is possible.

The special requirements of coating materials require the manufacturer to design systems capable of withstanding the abrasion and wear inherent in most processes. If materials of construction, systems and applications are designed correctly, there is a high probability that high-energy media mills will find new homes in coating-related products.

Automotive, architectural paints, pigment, pigment dispersions and specialty coatings manufacturers may use formulas requiring near- and sub-micron particle sizes, opening new avenues to achieving enhanced material properties.

For additional information, contact Custom Milling and Consulting, Inc. at 1246 Maidencreek Road, Fleetwood, PA 19522; e-mail sales@cmcmilling.com; or visit www.cmcmilling.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!