High-Performance Carbon Black Pigment Advances Meet Emerging Needs

Improved Waterborne Performance: Thanks to a technical modification of the furnace black reactor, it is possible to manufacture a new class of fine-particle-size carbon black to meet the more demanding dispersion and performance needs in waterborne formulations. These unique properties provide high jetness and a distinct bluish undertone, while maintaining good stability in waterborne applications.

Raw Material Reduction and Sustainability: The same technology used to provide high performance in waterborne applications can be further enhanced through surface modifications, and result in carbon black pigments that can give outstanding performance in both aqueous and solvent systems.

The coatings industry is pushing suppliers for more sustainable raw materials, in part to be less dependent on fossil fuel feedstocks – and related price volatility. Another driver is the move toward corporate sustainability. Although the move toward high-performance carbon black for waterborne coatings is a step in the right direction for eco-friendly formulations, it does not meet the need for sustainability. Therefore we developed a new grade of carbon black pigment using renewable feedstocks. This multi-functional carbon black allows formulators of coatings, inks and polymeric materials to develop truly sustainable products.

Improved Resource Management: Carbon black is often considered the most difficult pigment to disperse, especially in waterborne systems. It typically requires the use of milling equipment, special additives and long periods of milling. Our new dry dispersion technology allows for easy dispersion of carbon black into an aqueous system with a dramatic decrease in time, energy consumption and the elimination of dispersing aids.

To fully appreciate the impact of these developments, it is important to understand the general dispersion parameters and characteristics of carbon black pigments.

Dispersion Considerations for Waterborne Systems

Water is a highly polar solvent with high surface tension and insufficient wetting properties. Thus, for proper dispersion and stabilization of carbon black pigments in waterborne coatings, the use of wetting and dispersing additives is essential. The carbon black pigment and polymeric dispersion additive or binder must be compatible. Two ways exist to prepare waterborne coatings:

• A mill base consisting of: polymeric binder as an aqueous dispersion or solution (that is stable against temperature and shear forces), plus wetting agent, defoamer, amine and pigment.

• A mill base without binder consisting of: polymeric additives (instead of the binder), plus defoamer, amine and pigment. The advantage of this system is the high carbon black pigment concentration, improved coloristic properties and universal applicability.

Proper adjustment of the binder pH in both systems is necessary to maximize coating performance.

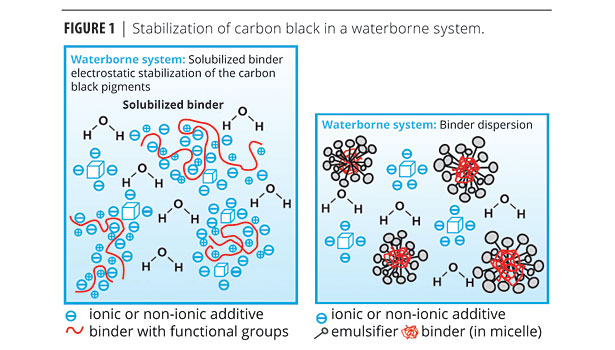

In waterborne coatings, electrostatic pigment stabilization is important. A mutual repulsion of pigment particles results from equally charged surfaces. To achieve this, the pigment surface is coated with ionic wetting and dispersing agents, or non-ionic agents with segments of different polarity. The choice of ionic or non-ionic additives depends on the properties of the pigment selected (Figure 1, p. 22). Furthermore, in waterborne dispersions, where the binder exists as polymer lattices (binder in micelle), there is almost no interaction between binder and pigment surface, so pigment dispersion must be assured by wetting and dispersing agents. In waterborne coatings, use of dispersing additives has always been essential, with concentration typically recommended in the range of 0.5 - 2 mg per m2/g particle surface area. However, a recent advancement by Orion in the area of dry carbon black pigment dispersions eliminates the need to use wetting additives and will be discussed.

Calculating Jetness and Hue

DIN 55 979, “Determination of the Blackening Value of Pigment Blacks,” provides a method for quantifying the degree of blackness or MY value. The color-dependent black value MC differs from MY by taking into account the precise undertone or hue of the black pigment. The hue value dM indicates the degree of brown or blue shade. It has been determined that the undertone of a black color also affects the visual assessment of jetness. A blue-shade tint, for example, increases jetness, while a brown-shade tint decreases jetness. The higher the value for MY and MC, the greater the perceived jetness or blackness. The higher the dM value the bluer the hue. A negative dM value indicates a brown shade. Table 1 (p. 22) shows the calculations to describe jetness and undertone.

High-Performance Carbon Black for Waterborne Systems

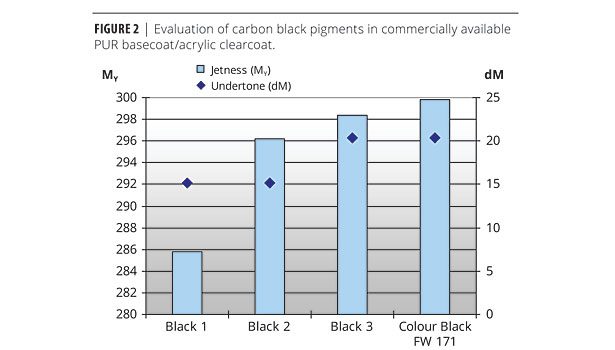

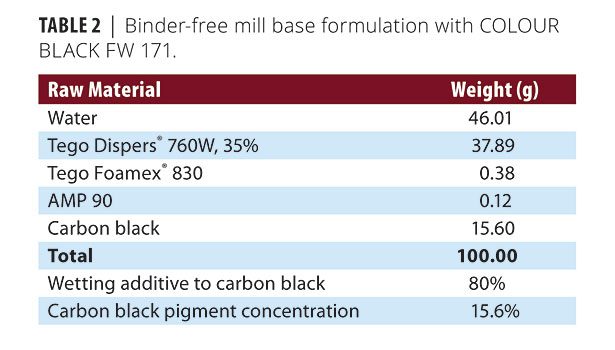

Technical modifications to the furnace black reactor resulted in a new class of carbon black pigment with very small mean particle size, narrow primary particle-size distribution and narrow aggregate-size distribution. The benefit of these unique properties is a carbon black pigment with high jetness, a distinct bluish undertone and very good stability in waterborne applications. To test the performance of COLOUR BLACK FW 171, a typical binder-free mill base was prepared (Table 2).

The performance of COLOUR BLACK FW 171 was tested in a commercially available PUR basecoat/acrylic clearcoat system using the mill base in Table 2. The concentration of carbon black pigment in the final letdown was 1%. A study was conducted versus other commercially available high-color carbon black pigments (Figure 2, p. 23). The data shows that COLOUR BLACK FW 171 outperforms the other pigments, providing higher jetness with a strong blue hue.

High-color, high-performance carbon blacks like COLOUR BLACK FW 171 are required to achieve superior exterior exposure performance and weathering. Although excellent UV performance is inherent with fine-particle-size carbon black pigments, coating manufactures continue to require two years of Florida weathering data. Unfortunately, weather conditions are unpredictable. The total UV exposure and precipitation in Florida can differ greatly from year to year and create unpredictable results with the same test sample. After exposure to environmental conditions, coated films can also show great differences in acid fastness, depending on whether their initial exposure was in a rainy period or from intense UV radiation (i.e., the primary difference between summer and winter in Florida).

To better predict the performance of high-color carbon black pigments, Orion utilizes the ADF (acid, dew and fog) weathering test. The ADF test consists of exposing paint specimens to different artificial weathering cycles in specially designed environmental test chambers. Weathering cycles were selected to best reproduce the harsh weather conditions in Florida. Different climatic conditions, such as UV radiation, heat and the application of distilled water or acid rain, alternate during the test.

The ADF test is the first test method to satisfy the following requirements:

• The climatic changes in the test chambers, simulating weather conditions in Florida throughout the year, are tightly controlled for constant, reproducible test conditions;

• Combination of an acidic atmosphere with UV radiation;

• Appropriate analysis in order to simulate the precipitation in Florida;

• Strong correlation between results of the outdoor tests in Florida and the simulated weather conditions.

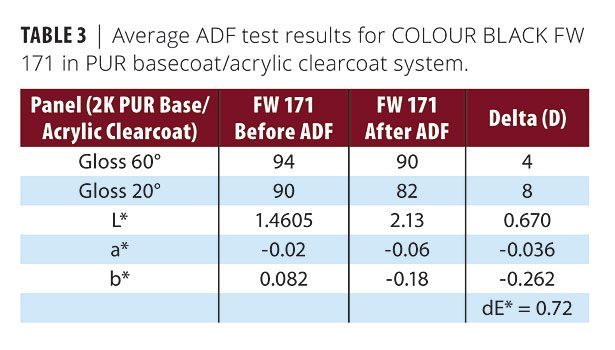

Table 3 (p. 24) displays the CIE lab and gloss results after 42 days of ADF testing for COLOUR BLACK FW 171 in a 2K PUR basecoat/acrylic clearcoat.

Carbon Black for Waterborne and Solvent-Based Systems

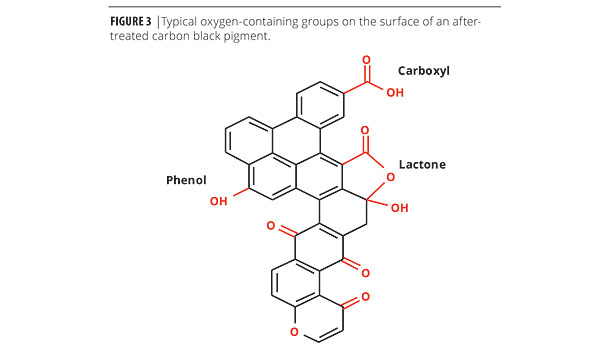

XPB 255 is an after-treated carbon black pigment. It is characterized by a very narrow distribution of mean primary particle size, as well as a narrow distribution of both primary particle and aggregate size. The after-treatment process generates a functional surface with oxygen-containing groups (Figure 3, p. 23).

When incorporated into a coating system, these groups induce better wetting and dispersion properties. An enhanced interaction with polar binders significantly improves the stabilization of carbon black pigments. The volatile content or degree of oxidization is often used to characterize oxygen-containing surface groups. XPB 255 has a 12% volatile matter at 950 °C.

The coloristic properties of XPB 255 were tested at a total carbon black pigment concentration of 2.2% in a solvent-based 2K PU coating system, based on an acrylic binder. Table 4 (p. 26) lists the formulation.

Figure 4 (p. 23) displays the color performance of XPB 255 vs. COLOUR BLACK FW 200, a popular high-performance carbon black typically utilized in automotive applications. XPB 255 shows a higher jetness (MY = 302) with less bluish undertone (dM = 5.6) compared with COLOUR BLACK FW 200 (MY = 289, dM = 11.5). The MC, which displays the overall visual impression of the final coating, discloses the significant improvement of XPB 255.

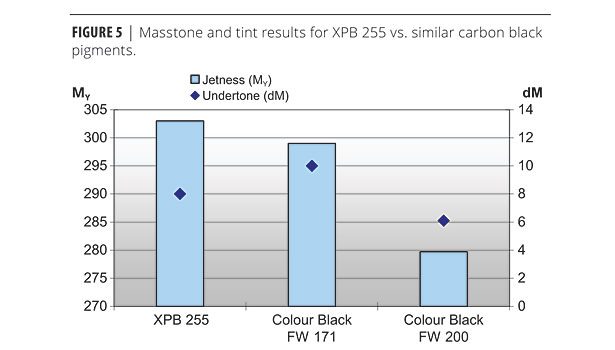

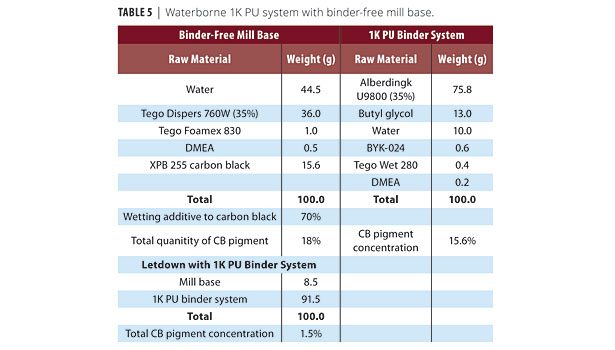

The coloristic properties of XPB 255 were also tested in a waterborne 1K polyurethane system with a binder-free mill base. To improve the dispersion process, as is typical in waterborne systems, 70% wetting additive on carbon black pigment was used. Table 5 lists the complete formula.

In the tested 1K polyurethane waterborne system (Figure 5, p. 24), XPB 255 displays higher jetness than COLOUR BLACK FW 171 and COLOUR BLACK FW 200. The bluish undertone is slightly less pronounced than that of COLOUR BLACK FW 171, but XPB 255 is universally applicable across 1K PU waterborne systems.

New Carbon Black Pigment from Renewable Feedstock

Orion Engineered Carbons developed PRINTEX® Nature, a new carbon black pigment based on renewable feedstocks such as plant oils for use in coatings, printing inks and polymer formulations. If the new pigment is combined with natural-based binder systems and bio-solvents, it is possible to achieve more than 90% sustainable content in a formulation. Performance is similar to that of traditional carbon black pigments, with colloidal properties that make it ideal for medium jetness and tinting. It can also be used in indirect food contact, where low PAH (polycyclic aromatic hydrocarbon) is necessary.

Testing shows PRINTEX Nature is well suited for a range of coating systems. Performance was evaluated in three types of formulations: 1) a solvent-based 2K polyurethane; 2) a standard alkyd/melamine baked enamel; and 3) a 1K waterborne. The renewable feedstock-based furnace black was compared to three other regular color furnace grades of carbon black with similar colloidal properties. Table 6 (p. 29) lists the 2K polyurethane test formulation.

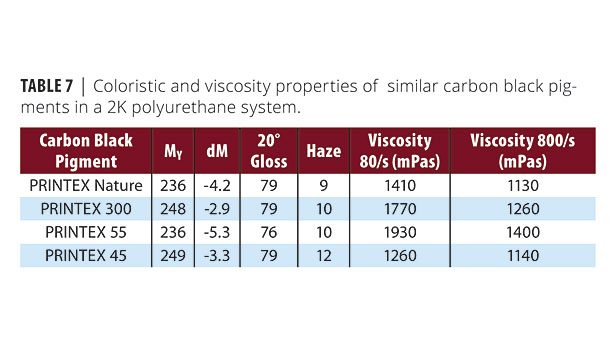

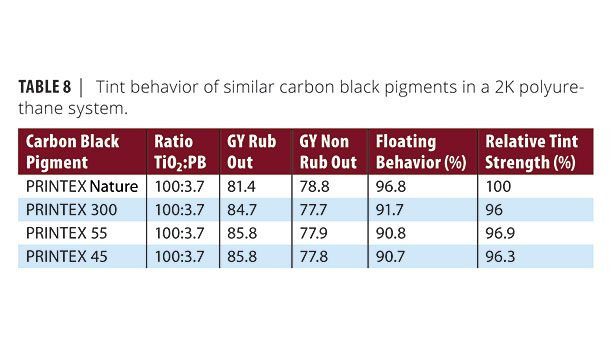

Tables 7 and 8 (p. 30) outline the masstone, tint, appearance and viscosity of the formulas.

PRINTEX Nature displays similar appearance properties to standard carbon black pigments in terms of haze and gloss. The viscosity of the samples also shows similar characteristics. Figure 6 (p. 24) displays the masstone data of the test samples.

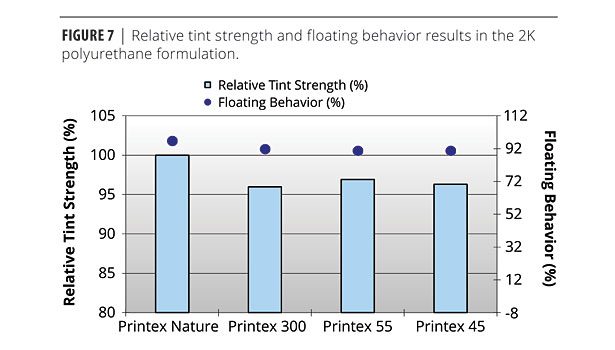

PRINTEX Nature and PRINTEX 55 had similar jetness, but PRINTEX 300 and PRINTEX 45 provided greater jetness than PRINTEX Nature in this system. The test samples all displayed a similar brown undertone, with PRINTEX 300 being the least brown. Figure 7 (p. 24) displays relative tint performance.

The test samples all displayed a similar tint performance; but PRINTEX Nature was the strongest and exhibited the best floating stability in a rub-up test.

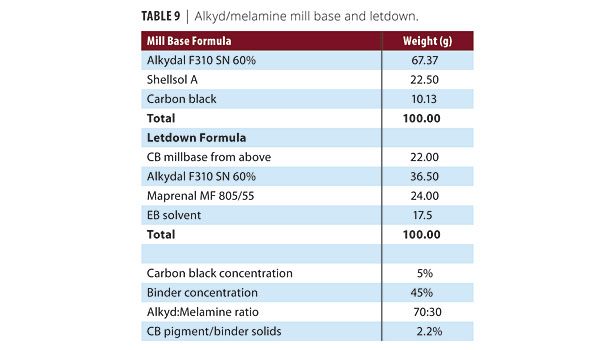

Next, the new plant oil-based pigment was evaluated in an alkyd/melamine baking formulation (Table 9, p. 30).

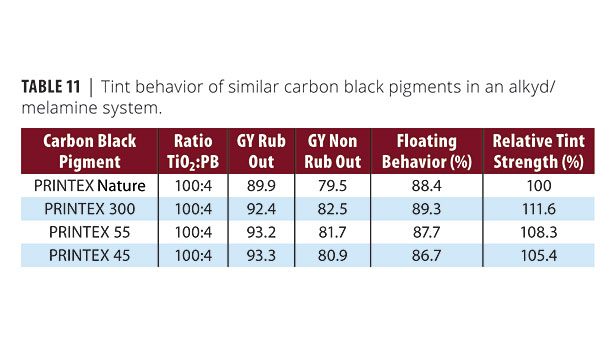

Again the performance of the new pigment was tested versus regular color furnace grades of carbon black. Results of the evaluation appear in Tables 10 and 11 (p. 30).

In the alkyd/melamine formulation, PRINTEX Nature exhibited a better appearance overall than the traditional carbon black pigments with a higher gloss value and less haze. It also displayed lower viscosity at low and high shear rates.

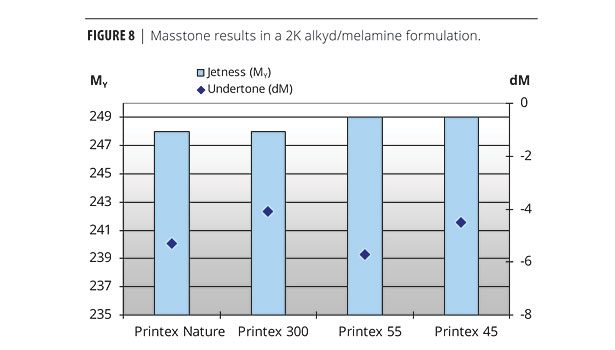

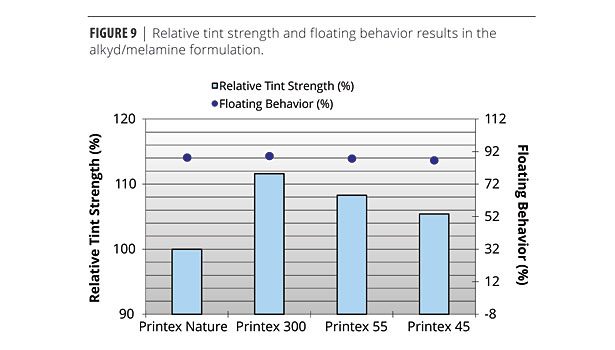

Coloristic performance of the new pigment more closely resembled that of traditional carbon black pigment in the alkyd/melamine formulation, both in jetness and undertone. However, the traditional carbon black pigments did display higher tint strength in this formulation (Figures 8 and 9, p. 26).

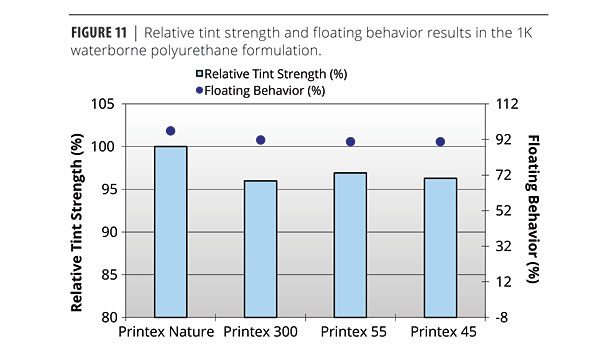

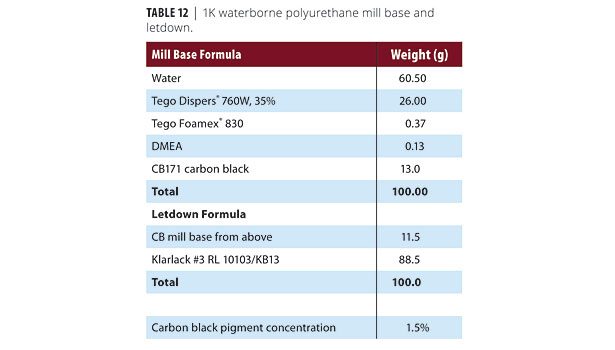

The final test formulation for PRINTEX Nature was a 1K waterborne polyurethane formula (Table 12, p. 30).

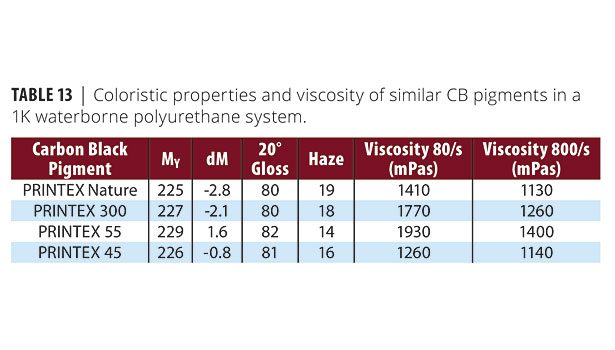

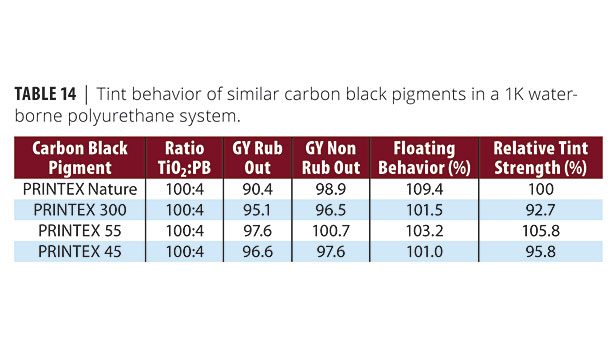

As with the other systems, XPB 440 was evaluated versus three standard regular color furnace grades of carbon black. Tables 13 and 14 (p. 31) outline the masstone, tint, appearance and viscosity of the formulas. Once again XPB 440 displays similar performance to the standard carbon black pigments.

Figures 10 and 11 (p. 26 and 28) display the masstone and tint data of the test samples.

Easy-To-Disperse Carbon Black for Top-Quality High-Jet Waterborne Systems

Pigment powders typically require thorough dispersion to achieve satisfactory development of coloristic properties. Carbon blacks are considered some of the most difficult to disperse in waterborne systems. One of the most common requests is for carbon black pigments that only require high-speed mixing to disperse. With this in mind, Orion Engineered Carbons developed XPB 430, a dry dispersion of carbon black with the following advantages over traditional products:

• Easy-to-disperse in water providing very stable pigment pastes within minutes;

• No milling or further wetting additives needed;

• Easy to handle free-flowing powder (carbon black pigment conc. = 52.6%);

• Excellent pigment stabilization providing higher jetness levels combined with a strong bluish undertone;

• Broad compatibility with most commonly used waterborne binder systems.

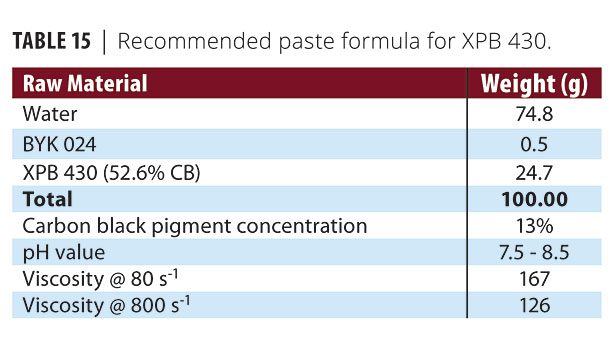

XPB 430 can be dispersed directly in water and develop the final coloristic properties within 5 to 10 min. A typical waterborne binder-free paste formulation for XPB 430 is shown in Table 15 (p. 31). A paste with 13% carbon black pigment is prepared by mixing water, defoamer and XPB 430 using a dissolver for 10 min. There is no need for intensive milling or addition of further wetting additives. The viscosity of the obtained paste is low. Fineness of grind is below 10 µm.

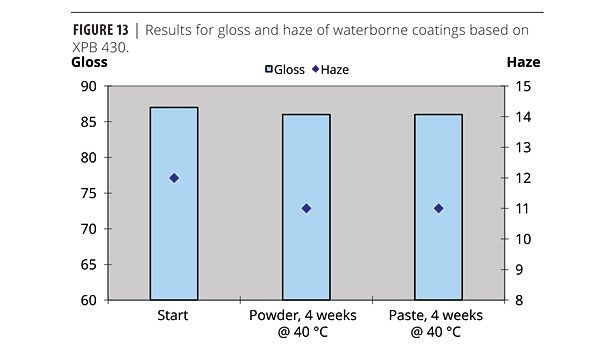

Storage stability tests were conducted on XPB 430 powder and the paste based on XPB 430 after storage at 40 °C (104 °F) for four weeks. No visual or measurable change in the quality could be detected with the dry dispersion powder or the paste. Final coatings with a carbon black concentration of 1.5% (typical for automotive) were prepared using a commercially available 30% PU dispersion (Alberdingk®U710, Alberdingk & Boley GmbH). The coatings were applied on glass plates (120 µm wet), flash-off for 15 min and force dried at 80 °C (175 °F) for 30 min. The coloristic and appearance results are shown in Figures 12 and 13 (p. 28 and 29). All of the coatings provided the highest level of jetness (MY of 325 to 330), a strong bluish undertone, high gloss and low haze. No change in the coloristic properties was obtained after storage, evidence of perfect stabilization of the carbon black pigment in the preparation as well in the paste and final coating.

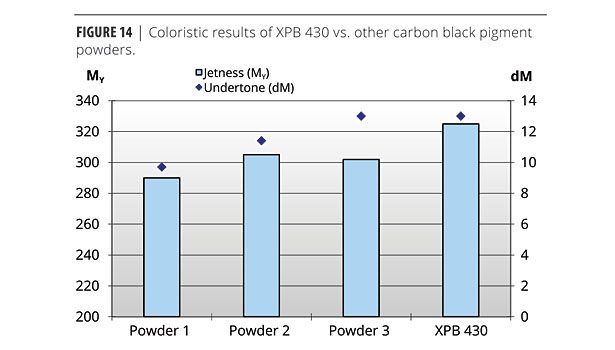

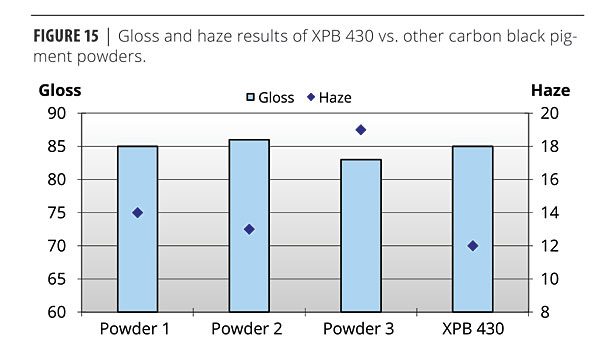

Figures 14 and 15 (p. 29) show the coloristic results of XPB 430 in comparison to several other commercially available high-jet carbon black pigment powders. In order to improve the dispersion quality of the traditional carbon black pigment powders and to stabilize the waterborne mill bases, 90% active wetting agent was used and milled with zirconium beads. (The XPB 430 did not require milling.)

The concentration of the carbon black pigments in binder-free mill bases was 13%. Final coatings with a carbon black concentration of 1.5% were prepared using a commercially available 30% PU dispersion (Alberdingk U710, Alberdingk & Boley GmbH).

XPB 430 provides high-gloss, low-haze coatings with the highest jetness values combined with very strong bluish undertones. The coloristic properties outperform even the best and extremely well stabilized competitive carbon black pigment powders stabilized with 90% active wetting agent.

Conclusion

Environmental coatings and the overall “greening” trend of the global coatings industry will continue to boost the demand for advanced waterborne systems. New high-performance carbon black pigments can offer a balance of properties including ready dispersion and coloristic properties to address emerging needs for coating, ink and polymer formulations.

Aknowledgements

Dr. Ariane Adolf, Dr. Kai Krauss, Christof Schilling and Thomas Weprich, Orion Engineered Carbons GMBH, Hanau-Wolfgang, Germany.

References

1 Lippol-Lohmer, K. Farbe und Lack, 92 11 (1986), 1024-1029.

2 TI 1204, “Method for Measuring Blackness of Pigment Blacks,” Degussa (2001).

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!