Innovative Pigments Provide Formulation Advantages

Growing Demand for Low-VOC Paints

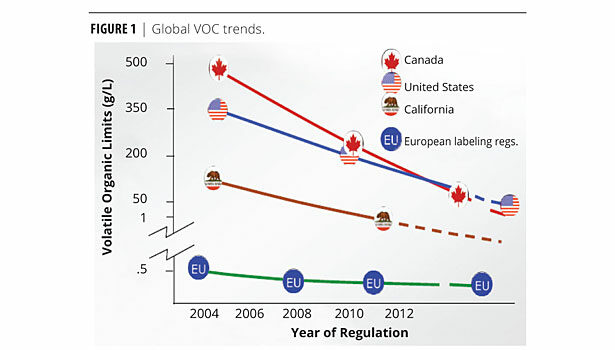

With a global trend toward lower VOCs and emissions, there has been a steadfast focus to reduce VOCs in architectural paints through the implementation of various environmental regulations and labeling programs (Figure 1). Rapidly changing regulations and certification requirements cause formulators to look to raw material suppliers to remain current and innovative for the best response to these changes. Further, there is a rising demand from the marketplace for coatings products with these environmental attributes, as well as enhanced coloristics, durability (i.e., fade and stain resistance) and ease-of-use.

Many of the ingredients that deliver premium performance in paints can also be the source of VOCs and alkylphenol ethoxylates (APEs). Indoor paints often emit VOCs that have an unpleasant odor, leading to poor indoor air quality. Some paints also contain APE-based surfactants that are questionable in their ability to biodegrade and may be toxic to aquatic life.

Challenging Times for the Formulator

Paint formulators are attempting to develop new products to reduce or eliminate VOCs/APEs to meet market demand and regulatory standards. They require a continuous feedback loop from the market on what product improvements are considered necessary. The question is, how do suppliers help formulators develop environmentally compliant paints that offer real value and performance for their customers?

Architectural paint manufacturer color palettes are effective visual marketing tools that provide a way to promote colors influenced by current market dynamics and trends (such as societal, economical, cultural, political, etc.). Color palettes help drive paint sales by offering consumers color choices and combinations based on specific themes (e.g., lifestyle, kids, retreat, etc.).

Architectural paint manufacturers have resisted switching point-of-sale (POS) colorants due to the labor-intensive task of possibly having to re-match entire color palettes. Therefore, there is little value in choosing a low-VOC colorant system that only offers colors with no additional value in performance properties. A better choice is a move to a colorant system that provides not only a wider color space but also enhances product performance. For example, the addition of higher-opacity colorants can help improve hiding, especially in deep-tone colors, making it unnecessary for multiple coat application.

Benefits of Eco-Colorant Pigment Technologies

Zero-VOC colorants enable formulators to address market demand for advanced architectural paint formulations without the pain of switching costs. Advantages include:

• Low odor, APEO-free and zero to low VOCs;

• No tip-drying issues with POS dispensing machines;

• Improvements on performance;

• Wider range of color possibilities, specifically for architectural applications;

• Built upon a sustainable chemistry platform.

Low-VOC colorants are the sustainable colorants of the future and are currently being utilized by many paint companies. The requirements of no- or very low-VOC and APE-free colorants are met. These innovative pigment technologies are universal colorants, so everything now tinted with conventional colorants can still be colored, but with added functionality. Overall, low-VOC colorants present many attractive options to meeting marketing, regulatory and technical goals for the formulator.

Feeling the Heat

Rising temperatures, increasing energy costs and expanding global population are key drivers as to why heat build-up has been growing in interest. There is also a growing trend endorsed by the proliferation of environmental programs and institutions, as mentioned.

It is commonly known that when placed in natural sunlight, a white surface remains cool, whereas a black one heats up. The cause is due to the contact of the coated surface of the substrate with the near-infrared radiation (NIR) emitted by the sun. When radiation is absorbed, light is physically converted into heat. The sun emits over 50% of its energy as NIR radiation (Figure 2). By using a conventional pigment, this effect could result in a build-up of solar heat due to the unwanted absorption of radiation from the sun. The shelf life of a material or substrate increases by protecting it from damage caused by solar heat build.

When selecting an effective IR-reflecting pigment, the most important factor is the total solar reflectance (TSR) value. TSR is the integral total amount of solar energy that is immediately rejected by a surface material (e.g., coating). It includes UV, visible as well as NIR radiation and, thus, is a key factor in determining solar heat build on surfaces.

Heat-Management Pigments Love Cool Solutions

For coatings formulators to prevail, it is essential to work with the right pigment materials. One of the most innovative options is the use of “heat-management” pigments − functional pigments capable of responding to change in the environment, such as solar heat build. It is possible for surfaces to remain cool by fortifying coatings with these “functional” pigments, enabling reflection of wavelengths in exposed NIR areas.

These heat-management pigments allow for the design of products that need to remain cool under the sun or heat, without sacrificing color or durability. Benefits include energy savings, longer product life, cooler cities (‘urban island’ heat effect mitigation), peak energy demand reduction and quality of life improvements.

The reflectance curve differences are also mirrored in varying results of heat build-up curves shown in Figure 3. In the heat build-up experiment, a coated substrate is exposed to artificial NIR light in a closed box under defined conditions. The temperature increase is measured in relation to its ability to reflect NIR exposure. By reflecting NIR radiation more proficiently, heat-management pigments provide coatings the ability to significantly reduce the surface temperature.

Conclusions

Being a sustainable solution, heat-management pigments can be used in a variety of applications, including architectural, industrial, transportation and automotive. They enable a more environmentally efficient use of resources and help to extend the shelf life of exterior coatings. To sum up, advantages of utilizing heat management pigment technologies include:

• Sustainable solution platform;

• Increase in coating reflectivity;

• Reduced surface temperature;

• Less cooling energy;

• Longer coating and substrate lifetime; and

• Reduced “urban island heat effect”.

Much more than just color, advanced pigment technologies incorporate highly sought-after functional characteristics. In addition to higher color intensity, excellent light fastness and greater color selections, today’s pigments are engineered to offer lower VOCs for better indoor air quality and heat management solar reflectance for lower surface temperatures.

Market and regulatory dynamics are dictating the demands of today and, more importantly, of the future. Coatings formulators are looking to provide low-VOC and heat-management paints – two growing areas of market interest. Therefore, it is critical for them to partner with innovative suppliers offering cutting-edge, sustainable pigment technologies with enhanced performance characteristics. By providing solutions that will enable architectural paint formulators to differentiate, it will enable them to offer best-in-class products to customers, while still being in compliance with national and state environmental regulatory mandates.

For more information, visit www.basf.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!