Planning a Smooth Colorant System Conversion

As previously noted in this article series, upcoming legislation changes will require U.S. paint companies to use colorant systems with low- or no-VOC content. Few companies are clear about what such a conversion entails, either in terms of the expected timeframe to implement the changes or the associated costs. When planned carefully and correctly, changeover day will be effortless, ensuring business continuity while mitigating problems. A successful transition can best be assured by working with a comprehensive tinting system supplier experienced in executing and managing such conversions. Sufficient preparation and planning before changeover day can also mark the beginning of a new and better business with increased profitability (Figure 1).

Once the decision is made to address conversion to a low- or no-VOC system, it is advisable to assemble a project team to ensure a smooth transition. The team should consist of relevant company representatives, and colorant and equipment suppliers. Ideally, one of the suppliers should be an experienced professional with proven experience in low-VOC systems conversions. It is desirable to find such an expert to assist in leading the project. A partner like this, with integrated tinting solutions including colorants, dispensing and mixing equipment, software, lab services, and color formulation databases is quite advantageous when a tinting system needs to be analyzed and updated.

Getting Started: Analysis is Key

The first step in beginning the conversion process is to take a close look at your current business situation. It is necessary to thoroughly analyze the current business model and future objectives. Who is the customer base? What products do they need? Are customer needs being met, or have customers and their needs changed over the years? Does the current product offering still match the customers’ needs? Will customer needs change in the future? The answers to these questions will help identify the required level of performance for the optimal tinting system.

In a second step, it is necessary to analyze whether the current tinting system set-up is profitable. If it is and if it fulfills all business objectives, the aim of the conversion is to carry on with the existing system and just replace the colorants. If the system is not profitable, a number of changes to the overall tinting system will become necessary and will be discussed further.

However, even if the general make-up of the current tinting system is to be maintained, modifications to equipment may still be necessary to ensure that the system continues to run smoothly after conversion.

Conversion Options

Depending on the analysis outcome of the current business state and the future business objectives, paint producers will choose between one of two conversion options. It will either be appropriate to choose a technology replacement, where the current colorants are substituted with coloristically identical low- or no-VOC alternatives, or an update will be made to the entire tinting system.

Option 1: Coloristically Identical Low- or No-VOC Alternatives

The low- or no-VOC alternatives of -glycol-based colorants contain the same pigments, but they do differ in terms of solvents and additives. They may therefore react slightly differently when mixed with base materials, resulting in a deviation from the intended color shade on the fan deck. Therefore it is necessary to check new colorant compatibility in terms of color acceptance with the base materials. If they prove to be incompatible, the problem can be resolved by making adjustments to the base materials. If the new colorants are identical in terms of color and consistency and do not cause any compatibility problems, the same color formulas can be used.

Option 2: Updating the Entire Tinting System

If business objectives require changing the entire tinting system, a new set of colorants will be devised. This gives the paint manufacturer an opportunity to move the business forward while differentiating itself from the competition. In this case, the lab will need to carry out a complete color-matching process. New characterizations of the selected colorants are required, resulting in modifications to the database including new color formulas, colorant names and prices.

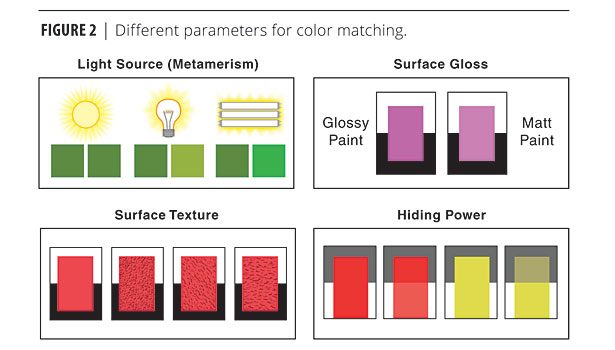

Color Matching a New System

It is important that the desired “matching parameters” that need to be obtained – i.e., level of color accuracy, surface texture or “hiding power” – are discussed up front, so the expectations of the customer match the outcome of the color matching process (Figure 2). Color accuracy can best be assured if all color evaluations are done under controlled daylight conditions. The standards that are to be used as reference should be specified in advance of the color matching process and, if possible in the case of specialty coatings, the final color match should be applied on the end substrate (i.e. façade) to ensure the best possible color outcome.

“Top-Off” vs. “Non Top-Off”

The lab also requires information on which “filling philosophy” the paint manufacturer wishes to follow. Adding colorant to the base paint changes the volume and weight of the paint being sold, so there is a choice between a “top-off” and a “non top-off” process (Figure 3). In the top-off process, the can is always filled to one hundred percent with base paint and colorant. This may mean that a certain amount of colorant is added to the can even if the desired color has already been achieved, which makes the product more expensive. In contrast, the non top-off tinting process allows a variable amount of final product to be sold. Once the required color is achieved, no additional colorant will be added, making it a cheaper process.

Because of the cost implications, most manufacturers would naturally opt for the non top-off alternative. However, it should be noted that there are country-specific regulations that require can labels to specify the exact amount of paint they contain. In the non top-off process, this would mean each can would need an individual label – a requirement that paint manufacturers would be unable to fulfill, whether for technical or cost reasons. This is why most often the top-off process is selected over non top-off.

In addition to the filling philosophy that will be used, lab experts working on creating color formulas also need to know the minimum can size to be sold and the smallest shot size of colorant that can be dispensed by the equipment. This information is important for accuracy and repeatability of the end product.

Matching Rules

Once the matching parameters are set and the necessary information has been given, the matching rules can be defined according to the desired final outcome. Examples of matching rules include: the required weather fastness of the tinted paints; the influence that price is allowed to have over accuracy; or limits as to how much or how little colorant can be added to the base material at any one time.

In order for the matching process to begin, the required colors of the specified fan deck need to be available in a database format. Color matching can then be carried out either through purely mathematical calculations, or by combining mathematical calculations with visual control. This would entail making a draw down and correcting the formula until the color reaches the required standard. The acceptable tolerance and formula rules are based on prior agreements with the customer.

The perfect color formula will also take colorant consumption into account. Each colorant in a tinting system needs to achieve a reasonable turnover to remain fresh and to retain its properties. Colors are formulated so that slow-moving colorants are utilized wherever possible. While this may result in some color formulas being more expensive, the overall cost of ownership will be reduced. By maximizing use of the slow-moving colorants you reduce the risk of them drying up or causing technical problems. The result is superior tinting system performance.

Equipment Compatibility

While the color matching process takes place in the lab, the compatibility of the new colorants with the installed base also needs to be assessed. If the equipment needs to be adapted, the project team will consider whether the machines can easily be retrofitted at point-of-sale – for example by replacing nozzles or valves – or whether more substantial work or replacement of the machines is necessary.

If colorant viscosity is high, it may be necessary to install larger valves and tubing with greater diameters. Since low- or no-VOC colorants tend to dry out more easily than glycol-containing ones, older equipment will need to be retrofitted with a nozzle closing or humidification system. It may also be advisable to change canister sizes, or to adjust stirring times as necessary.

Maximizing Production Efficiency with the Right Software

Tinting systems rely on software in more ways than one. There is, of course, tinting software that includes the database and color formulations. But there is also software integrated into the equipment to control its performance. Both software types require periodic updates. Converting to a new colorant set is the perfect opportunity to carry out a software update to improve system performance.

Software development in the tinting business is continually evolving; new and updated features can enhance tinting system performance. New software may be required in combination with colorant and equipment changes or a new tinting system. Currently, Chromaflo has a new software application in the pipeline called Innovatint. Several versions will be available, each with different options, including: the automatic exchange of product and tinting information about customers between different locations; statistical data about the installed databases to assist with cost and resource planning; as well as supporting off-site user support and automatic software updates.

Preparing for Changeover Day

To assess exactly what kind of equipment adaptations will be necessary, information regarding equipment type and age, as well as colorant turnover, needs to be collected from each point-of-sale system. The ownership situation of the installed equipment base also needs to be considered. Some companies own all the dispensing and mixing equipment in their shops; others have shops run by managers who have invested their own money in equipment. The accumulated equipment and ownership data will then form the foundation for the steps that need to be taken to ensure a successful system conversion.

The timing of ordering and delivering new colorants is equally crucial for a smooth transition. Colorants need to be available on changeover day, but they should not be ordered too early to avoid sitting on shelves too long before being used. A decision will need to be made as to what will be done with the old colorants. Pouring a VOC-free colorant over a glycol-containing colorant is certainly possible. But in some cases, even if the two are coloristically compatible, they may not mix well, resulting in unsolicited viscosity increase, gel forming or separation. In these instances, the old colorants will need to be replaced entirely. Ideally, they can be used by being transferred to higher-output locations for fast consumption. If this is not possible, they should be collected and disposed of professionally.

With all these factors in mind, the project team will devise a project plan for the conversion, including opening hours at point-of-sale on the day the system is converted.

Changeover Day at Point-of-Sale

If all steps of the preparation phase have been taken, changeover day at the point-of-sale can then be addressed. Depending on which changeover option is selected − technology replacement or a full tinting system update − the complexity of the work to be undertaken varies and may include replacing the equipment altogether. The decision as to whether the changeover is completed on- or off-site can vary between different outlets within the same company, as opening times and acceptable machine downtimes may differ.

Changeover Day -Technology Replacement

(Option 1)

On-site technology changeovers, where VOC-containing colorants are substituted with coloristically identical alternatives, can generally be executed within a day. The machines are manually cleaned, small adaptations are made such as replacing valves or nozzles, new colorants are poured in, and the circuits are ventilated and calibrated. However, if the new colorant set is not compatible with the old one, the installed equipment base has to be cleaned very carefully in order to avoid chemical reactions that could potentially harm the machine or influence the paint quality. Sensitive parts of the circuit, like valves and tubes, are especially susceptible to old colorant sediments. These parts should be exchanged with new parts for the most optimal end-product results. The extent of retrofitting measures required determines whether the conversion can be done at the shop or if the installed equipment has to be removed and replaced by temporary equipment.

Changeover Day - Full Tinting System Update

(Option 2)

Changeover to a new customized tinting system is a bit more complex. It is not just the machines that need to be calibrated and prepared for the new set-up – software, including the database and color formulas, also has to be installed. In order to minimize downtime of the installed equipment, the conversion can be completed outside opening hours. The service technicians may also have a mobile workshop to carry out the retrofitting on site. This option greatly simplifies system conversions for big companies with numerous outlets.

Installing a new machine is the least time-consuming option as the machine is set up and prepared in advance. Within half a day, service technicians can dismantle the machine, get it ready for transport and install the new machine. An interim solution, in contrast, would require technicians visit the shop twice, spending around two days in total on setup and dismantling.

Well-planned conversions carried out by a competent team of service technicians will minimize disruption at point-of-sale on changeover day. Having technicians on-site for changeover day will also allow them to instruct and train the local staff to master any changes in the handling of the converted tinting system.

Ready for a Low-VOC Future

Thorough preparation and selecting the right conversion partner are imperative to the success of a tinting system conversion. As we have seen, even a straightforward technology change that does not involve changes to the pigments or color characteristics of the colorants requires careful planning, thorough analysis and testing, and potentially some changes to the point-of-sale equipment. Paint companies are therefore well advised to choose a tinting system partner like Chromaflo, who understands all aspects of the process, including colorants, equipment, lab services and software with an expansive service network. Ultimately, conversion is a process that is individual to each business. There is no “one size fits all” conversion solution. But with the right partner and thorough advanced planning, a system conversion prompted by legislation change can be an ideal opportunity to take the business to the next level to improve both performance and profitability.

For additional information, contact Bart Wilbanks, Technical Account Manager, Colorants, Chromaflo, at 800/728.8408, ext. 240.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!