Self-Healing Systems for High-Performance Coatings

The self-healing polymer system described by White et al. in 20011 was based on the Grubbs’ catalyst-initiated ring opening metathesis polymerization (ROMP) of dicyclo-pentadiene (DCPD) in the site of damage, thus healing the damage and restoring structural continuity. While a successful demonstration of microcapsule-based self-healing technology, this approach was not deemed viable for commercial applications due to the chemical stability and cost of the catalyst. Several new chemistries have since been developed for applications in elastomers,2 coatings3 and composites.4 In this paper, we evaluate the application of polydimethylsiloxane (PDMS)-based chemistries in the development of self-healing coatings for heavy-duty industrial and marine applications.

Thermoset Coating Applications

Thermoset coatings such as epoxy and epoxy vinyl ester coatings are typically used in aggressive industrial and marine applications due to their chemical and corrosion resistance. However, when these coatings are eventually compromised due to environmental factors and heavy usage, the substrate is exposed, leading to the rapid onset of corrosion. Significant corrosion ultimately leads to the need to take the equipment off line for maintenance. A PDMS-based self-healing system that gives the material the ability to repair mechanical damage without the need for external intervention has been developed.3

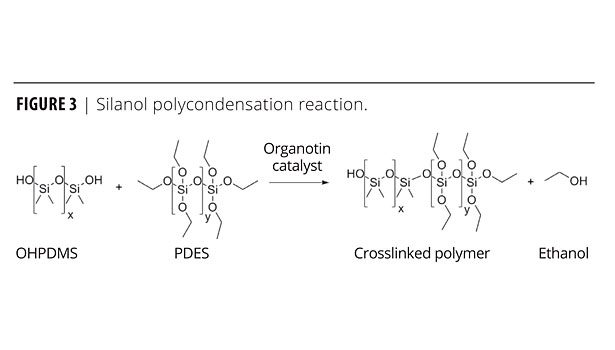

The self-healing system depicted in Figure 2 is comprised of two varieties of microcapsules. The first type contains a mixture of hydroxyl-terminated PDMS (HOPDMS) and polydiethoxysiloxane (PDES) and an appropriate solvent, which was added for the purpose of viscosity modification. The second type contains a blend of a tin catalyst and a solvent encapsulated together in a polyurethane microcapsule. Both capsule varieties were added to the coating prior to application on the substrate. Damage to the resulting coating ruptures the microcapsules, releasing their contents into the site of damage where they mix, react and polymerize to repair the damage. Figure 3 illustrates the reaction that occurs in the site of damage. The hydroxyl-terminated PDMS reacts with the PDES in the presence of the organotin catalyst. The reaction results in a crosslinked network and releases ethanol as a condensation product.

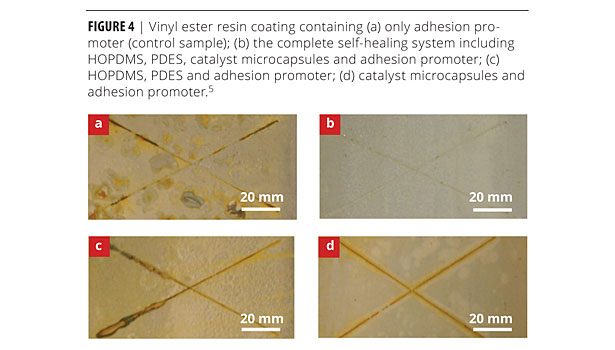

A preliminary demonstration of the performance of this self-healing system is shown in Figure 4. Four versions of the same epoxy vinyl ester coating were prepared and applied to cold-rolled steel substrates. The first version (Figure 4a) was a basic control sample containing no self-healing additives. The second version (Figure 4b) was a complete self-healing system containing both the resin microcapsules (containing HOPDMS and PDES) and the catalyst microcapsules (containing the organotin catalyst). The third version (Figure 4c) only contained the resin microcapsules, while the final version (Figure 4d) only contained the catalyst microcapsules. All samples were allowed to heal at 50 °C for 24 h prior to immersion in a salt solution for 120 h.

The resulting samples reveal two important observations. First, the addition of a complete self-healing system upgrades a basic traditional coating to a fully functional self-healing coating. Second, self-healing is dependent on the restoration of barrier properties to the damage site as a result of the formation of new polymeric material due to the reaction of the contents of both varieties of microcapsules. Similar observations were made with fully formulated commercial epoxy and epoxy vinyl ester coatings.

Application in Elastomeric Coatings

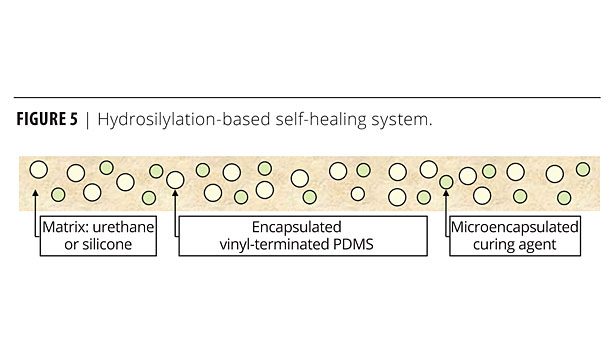

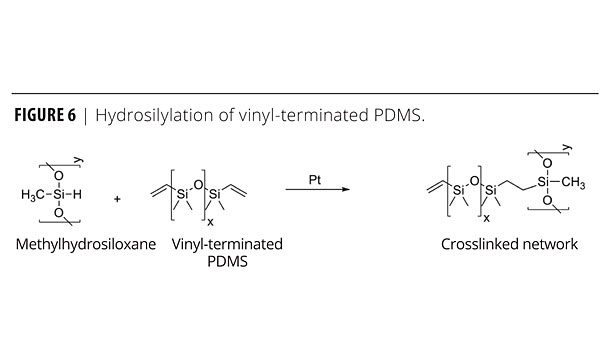

We have also demonstrated self-healing functionality in elastomeric coatings such as silicones. Building on the work of Keller et al,2 we have developed a different PDMS-based self-healing system for application in silicones and other soft coatings. This system is based on the Pt-catalyzed hydrosilylation of vinyl-terminated PDMS. As was the case for the system described in the section above, the resin and curing agent components of the polymer system were microencapsulated in two varieties of microcapsules and added to the coating prior to application on the substrate (Figure 5). Damage to the resulting coating ruptures the microcapsules, releasing the contents to the site of damage where they mix, react and polymerize. A schematic of the reaction is shown in Figure 6. The vinyl-terminated PDMS resin reacts with an active methylhydrosiloxane in the presence of a platinum catalyst to yield a crosslinked network.

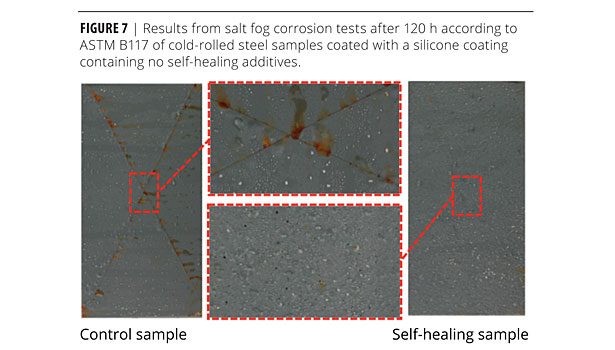

The self-healing system was evaluated in a commercially available silicone coating, which is marketed as a corrosion-resistant coating. Figure 7 exhibits two versions of the same coating applied to cold-rolled steel substrates. The control sample was applied as received from the manufacturer, while microcapsules containing the self-healing agents were added to the self-healing sample. Both samples were scribed, allowed to heal at room temperature for 24 h and then exposed to a salt fog according to ASTM B117 for 120 h. As expected, the control sample was observed to rust within and around the scribed region. Blisters were also observed around the scribed region of the control sample. The scribe on the self-healing sample was observed to heal, extending the protection of the substrate. No rusting or blistering was observed anywhere on the sample (Figure 7).

Conclusion

We have demonstrated the successful translation of self-healing technology originally designed for polymerized resins and reinforced polymer composites to coatings. Two different PDMS-based chemistries were used to achieve self-healing functionality in commercial thermosetting and elastomeric coatings. The samples exhibited in this article were prepared by drawing down coatings containing self-healing microcapsule additives. However, we have demonstrated the ability to apply similar coatings using siphon-feed spray guns and high solids static mixing spray systems and confirmed the survival of the microcapsules through this application process.

This paper was presented at SSPC 2011 in Las Vegas, NV, and was also published in the August 2011 issue of the Journal of Protective Coatings & Linings.

References

1 White, S.R.; Sottos, N.R.; Geubelle, P.H.; Moore, J.S.; Kessler, M.R.; Sriram, S.R.; Brown, E.N.; Viswanathan, S. Nature 2001, 409, 794-797.

2 Keller, M.W.; White, S.R.; Sottos, N.R. Adv. Func. Mater. 2007, 17, 2399-2404.

3 Cho, S.; White, S.R.; Braun, P.V. Adv. Mater. 2008, 20, 1-6.

4 Caruso, M.M.; Blaiszik, B.J.; White, S.R.; Sottos, N.R.; Moore, J.S. Adv. Func. Mater. 2008, 18, 1898-1904.

5 Cho, S.; White, S.R.; Braun, P.V. Adv. Mater.2009, 21, 645-649.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!