New Admixture Technology to Extend Durability of Concrete

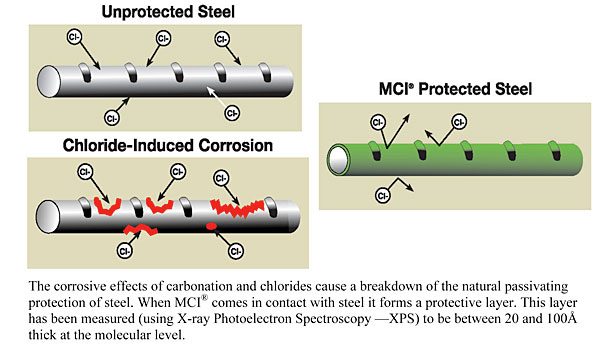

A unique feature of MCI 2005 is that it can migrate a considerable distance through concrete, forming a corrosion-inhibiting protective layer on metals. It maintains structural integrity and extends the service life of concrete structures while being environmentally friendly MCI 2005 is ambiodic (mixed), meaning it protects both anodic and cathodic areas within a corrosion cell.

It contains a synergistic blend of aminoalcohols and salts of carboxylic acids, which form a protective molecular layer on embedded reinforcement, protecting against corrosion even in the densest concrete. MCI 2005 has been used in numerous applications worldwide including Princess Tower, Dubai – the world’s tallest residential building; construction of a new drinking water reservoir in Guayaquil City, Ecuador; as well as the 829.84 m tall Burj Khalifa Tower, the world’s tallest building ever built, whose construction used 330,000 m3 of concrete.

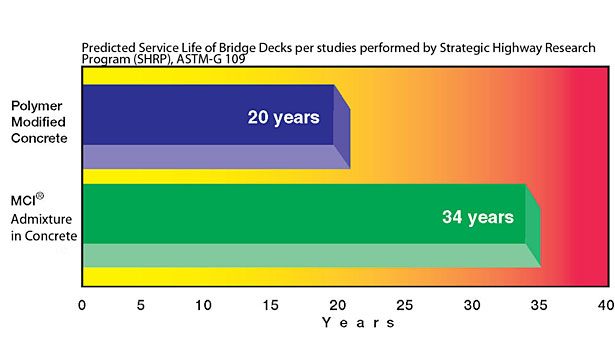

After a thorough review of multiple technologies, MCI 2005 was chosen to be incorporated in the concrete mix design to extend the service life of the buildings, which are exposed to airborne salts and harsh groundwater conditions. This corrosion-inhibiting admixture is environmentally friendly, non-toxic, non-flammable and is bio-based (produced from sugar beets, a renewable resource). It does not contain any nitrites and will not adversely affect any physical properties of the concrete mix. It is lab and field tested worldwide. MCI 2005 conforms to ASTM G109 - Standard Test Method for Determining Effects of Chemical Admixtures on Corrosion of Embedded Steel Reinforcement in Concrete Exposed to Chloride Environments, and has approval to meet NSF Standard 61 approved for potable water applications.

For more information, visit www.cortecvci.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!