IR-Reflective Pigment Helps Conserve Energy

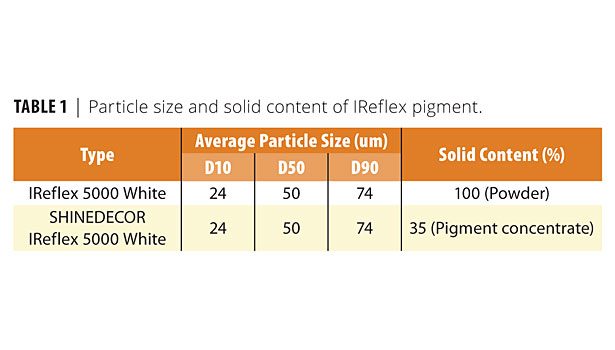

Aluminium shows the highest heat-reflection properties compared with other metals. IReflex uses this salient characteristic of aluminium pigments to achieve a maximum IR reflection. IReflex is environmentally friendly, as it is free of solvents and water pollutants (it complies with the requirements of the Ecolabel). It is available as a powder or a ready-to-use pigment concentrate (Table 1), and is simply stirred into transparent interior wall paints. For the highest protection possible of the stabilizing layer of the pigment, IReflex should be added to the paint carefully and at low shear forces. Strong shear forces can damage the pigment and result in an impairment of the effect. The desired color shade can be obtained by adding organic color pigments (Figure 1). The IR reflection behavior is not impaired by tinting colors. The paint can then be applied with all usual application methods. IReflex can be used in many applications, especially interior wall paints, but can also be used in wood coatings, facade paints, coil coating, etc.

IReflex causes the heat energy, or the warmth emanating from the human body, to be reflected back into the room instead of being absorbed by the walls and ceiling. The heat reflection from the walls back into the room results in improved thermal comfort of the human body. The high-yield IReflex pigment works according to the thermos flask principle − in winter, the heat is reflected back into the room and stays inside. In summer, however, IReflex prevents the heat from getting inside the room. IReflex is especially suited for the energy-efficient modernization of existing buildings, as no construction work is necessary.

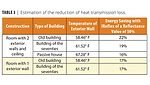

With a pigmentation level of approximately 10%, IReflex shows reflectance values of 50 %. In comparison, white interior wall paints reach a reflectance value of only 5% in a mid-IR range; i.e., 95% of the heat energy is absorbed by the wall. The higher the amount of IReflex pigment used in the paint, the higher the reflectance value of a wall paint (Table 2). If conditions are ideal, and if 10% of IReflex is incorporated into the wall paint, 22% of the heating costs can be saved.

The surface also plays an important role in increasing the reflectance value. The best reflectance values can be obtained by applying the wall paint with IReflex on a smooth surface. This effect is shown in Figure 2.

Study by the Bauhaus University in Weimar

Extensive research was conducted in co-operation with the Bauhaus University in Weimar (department Faculty for Building Physics) in order to prove the efficiency of IReflex. The study was carried out in a special climatic room measuring 9.84 x 9.84 x 8 ft. The walls and ceiling of the room were painted with a standard interior paint, and with an interior paint containing IReflex. NTC sensors that controlled the actual surface temperature were installed at different wall surfaces of the room. Specifically for this study, a sensor was installed and programmed in order to control the room temperature via the floor heating; the setpoint value was set to 69.8 °F.

In order to examine the influence of the building construction, different wall constructions and the surface temperatures connected with them were simulated. The U-values (thermal insulation values) of:

• 1.64 W/m²K (old building) / USA: R value approx. R-3;

• 1.11 W/m²K (building of the seventies) / USA: R value approx. -5; and

• 0.12 W/m²K (new low-energy house) / USA: R value approx. -47

were set in order to estimate the surface temperature of the exterior wall under the influence of the wall construction.

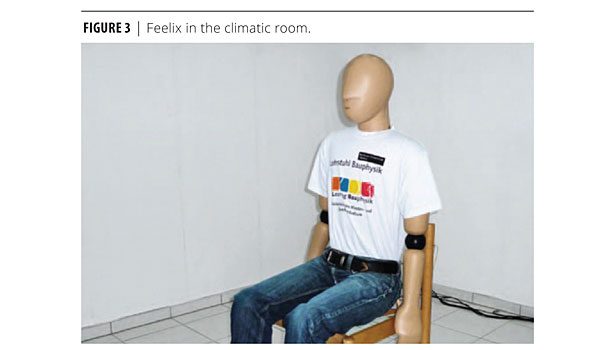

In order to measure the thermal comfort, an artificial model named Feelix was used (Figure 3). Feelix was covered with a special kind of plastic with 7000 metres of cable underneath that made it possible to simulate the temperature and feeling of human skin. Via different control modes, the surface temperature, the heat flow or even a comfort mode could be simulated.

The studies were based on the conditions of the German DIN standard 4108-2 regarding a minimum requirement to heat insulation (thermal bridges) with the following conditions:

• Floor heating;

• Outdoor temperature of 23 °F;

• Room temperature of 69.8 °F;

• Application of IReflex with a reflectance value

of 50%; and

• Heat flow density of Feelix: q = 70.2 W/m².

The results showed that the application of interior wall paint with IReflex significantly reduced the loss of transmission heat from the walls to the outside. After the application, the wall reflected the heat back into the room. The “human” body needed to produce less energy for the heat exchange and felt less cold. The thermal comfort of Feelix increased and the supplied heat output could be reduced. Accordingly, less heating energy was required to keep the thermal comfort at a constant level. The results of the research carried out by the Bauhaus University in Weimar highlight the high energy savings potential in the field of older buildings, or low-energy modern buildings (Table 3).

Conclusion

The study proves that the increase of the reflectance value of an interior wall paint results in energy savings. As the savings potential significantly depends on the surface temperature of the outside walls, the insulation of the building is important. The results of the research carried out by the Bauhaus University in Weimar highlight the high energy savings potential, especially in the field of old buildings. The poorer the heat insulation of a building, the more energy can be saved by using IReflex.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!