Zero-VOC, Nonionic Associative Rheology Modifiers

For the Next Generation of Environmentally Friendly Coatings

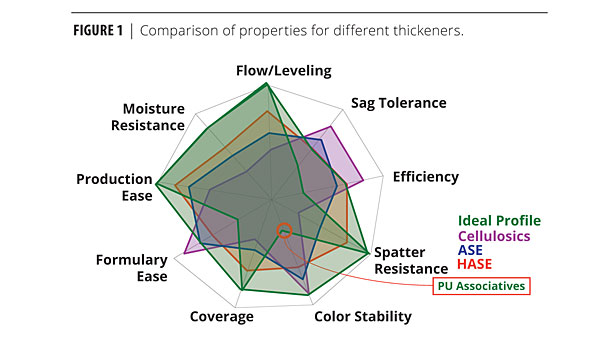

Associative thickeners play an important role in defining the rheology of waterborne latex paints. These materials include hydrophobically modified ether-urethane (HEUR) polymers, hydrophobically modified cellulosics and hydrophobically modified alkali-swellable emulsions (HASE). In comparison to water-soluble thickeners such as cellulose or acrylic copolymers (alkali-swellable emulsions), paints made with associative thickeners show better performance in sag and leveling, moisture resistance, spatter resistance and coverage (Figure 1). In addition, mixtures of associative thickeners allow one to tailor the rheological profile to provide superior paint performance.

However, one of the most difficult problems to solve with associative thickeners has been the viscosity instability with the addition of colorants. This phenomenon is known in the industry as “viscosity loss” and has resulted in poor coating properties and increased formulation complexity.

The effect of viscosity drop can be quite severe, resulting in thin coatings, poor coverage, increased sagging and poor color rub-up. In addition, there can be significant color-to-color variation with the amount of viscosity drop observed, and therefore significant variations in color values (such as ∆E and ∆L) in the final dried coating (Figure 2).

Environmental Regulations

Environmental regulations have resulted in the coatings market shifting from traditional oil- and solvent-based coatings toward more compliant systems. Included in these compliant systems are water-based paints, which have seen a drastic reduction in VOCs over the past few years.

With the advent of new resin and additive technologies, it is now possible to make water-based paints ranging from low to zero VOC. However, this move toward compliance brings another set of challenges for paint formulators. Glycol removal from water-based paints creates issues with freeze/thaw resistance and open time. Lack of open time or faster drying time compromises paint application properties, especially the balance of sag resistance and flow and leveling.

To aid in combating the issues discussed previously, Elementis Specialties has introduced a new thickening technology for waterborne coatings.

New-Generation Nonionic Rheology Modifiers

Innovative associative rheology modifiers are the newest high-performance thickeners designed for use in modern low- and zero-VOC binder systems across a broad range of chemistries. This advanced technology provides excellent sag resistance, while maintaining the superior flow and leveling performance associative thickeners are known for. Compared to other associative thickeners, they markedly reduce viscosity loss on tinting and have excellent color properties, even in deep and clear tint bases where large amounts of colorants are usually employed.

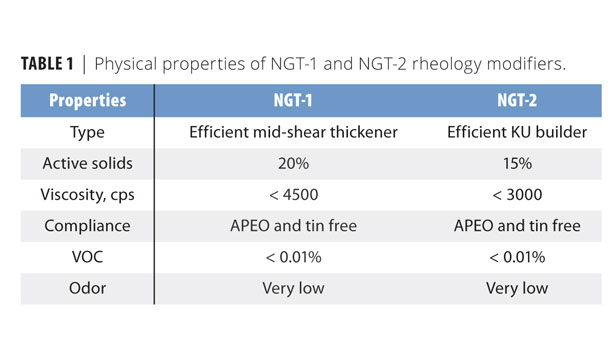

The architecture of the new-generation zero-VOC associative rheology modifiers represents the current state-of-the-art thickening technology for waterborne coatings. Decades of experience in urethane and polyether thickener design inspired the structure of these rheology modifiers. This unique structure utilizes custom-designed hydrophobes and backbone components coupled with a finely tuned molecular weight designed to provide the most effective balance between efficient thickening, color viscosity stability, application rheology and color properties. The new-generation thickeners (NGT-1 and NGT-2) are zero VOC, APEO- and tin-free. Both products provide high efficiency and outstanding balance of sag resistance and flow while minimizing viscosity loss upon tinting. Both products are compatible with a wide variety of latexes. Physical properties are listed in Table 1.

Unique Structure

The architecture of the new-generation rheology modifiers is based on decades of experience designing both traditional and branched thickener structures. Traditional associative urethane thickeners have a more linear structure, while polyether polyol thickeners have a branched structure that provides additional resistance to viscosity loss.

Colorant addition on tinting introduces large amounts of surfactants. These surfactants may displace the thickener from the latex surface, reduce the number of associations between the latex and the thickener, and thus reduce the viscosity of the paint. The unique branched structure of these rheology modifiers provides superior resistance to viscosity loss on tinting.

Customized Hydrophobes

Most associative thickeners are produced from commonly available hydrophobes. Elementis’ expertise in surfactant chemistry has allowed custom design of hydrophobes for these high-performance thickeners. Future generations of new thickeners will also be based on these custom hydrophobes to meet the demands of new binder technologies.

Zero-VOC Technology

Traditional associative thickeners rely on VOC-containing solvents to reduce thickener viscosity for ease of handling and incorporation. While designing zero-VOC associative thickeners, it is particularly challenging to maintain a low viscosity for easy handling in a plant environment. Elementis’ patented viscosity suppression technology allows the new rheology modifiers to be handled easily without compromising durability, dirt pickup or stain resistance. Unlike other associative thickeners, these new thickeners are shelf stable and will not separate during storage or contribute to syneresis in the finished paint.

Applications Data

NGT-1 and NGT-2 were evaluated in several waterborne paint formulations versus commercial KU builders. For the purpose of this article, two of the paint formulations evaluated will be discussed in detail.

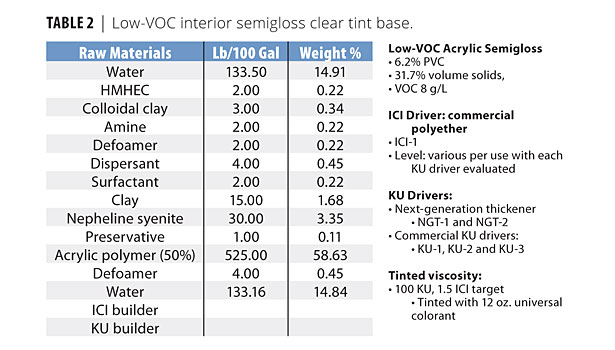

Formula 1: Low-VOC Interior Latex Semigloss Clear Tint Base (Table 2)

Modifiers NGT-1 and NGT-2 were evaluated against three competitive commercial KU builders; KU-1, KU-2 and KU-3. A commercial, polyether-type, high-shear viscosity builder, ICI-1, was used in combination with all the different NGT and KU thickeners tested in this study.

Rheology modifier levels were adjusted to achieve a tinted viscosity target of approximately 100 KU and 1.5 ICI. For best results, we recommend a ladder study that first adjusts the level of KU builder to achieve the target tinted viscosity, and then establish the level of ICI builder required to achieve tinted viscosity targets.

The new-generation zero-VOC rheology modifiers reduced the VOC content from 18 g/L down to 8 g/L. The clear base was tinted with 12 oz. of universal colorant (9 oz. color + 3 oz. white). Colors evaluated in this study were phthalo blue, lamp black and red oxide.

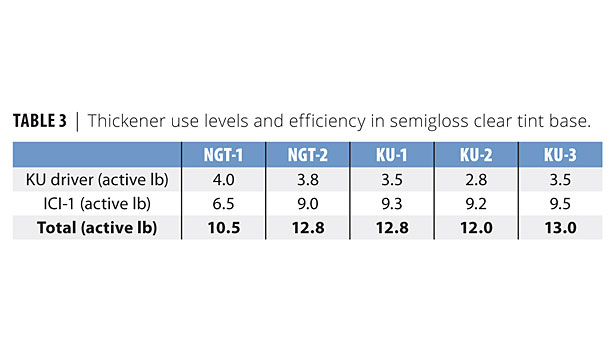

In terms of total active thickener, the new rheological additives provide up to 30% more efficient thickening. NGT-2 provides efficient KU build but less ICI contribution compared to NGT-1. In this case, the additional ICI contribution from NGT-1 reduced the overall use levels by 20% (Table 3).

Table 4 shows that NGT-1 and NGT-2 exhibited better mid-shear (KU) viscosity stability upon addition of colorants when compared to the competitive products. This allows for the base paint to be formulated at a lower initial viscosity, resulting in an overall reduction in rheology modifier usage (cost savings) and improved batch processing time.

Table 5 shows that the new zero-VOC thickeners have better high-shear viscosity (ICI) stability upon addition of colorants. This helps to improve brush leveling when compared to the competitive products.

Superior Balance of Sag Resistance, and Flow and Leveling

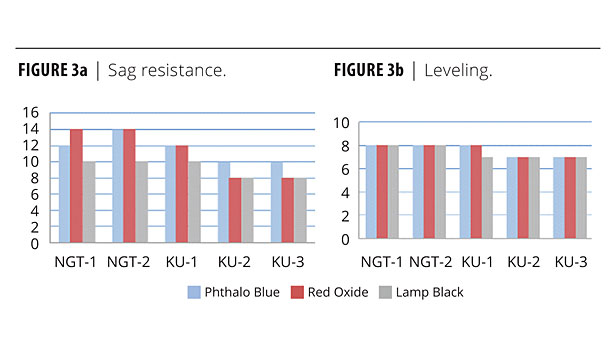

As shown in Figures 3a and 3b, the new zero-VOC thickeners not only provided excellent sag resistance on tinting due to superior viscosity stability, they also improved brush leveling compared to traditional associative thickeners.

The structures of the new-generation zero-VOC thickeners are designed to regain their viscosity slightly more slowly after shearing than traditional thickeners, resulting in superior leveling while maintaining excellent sag resistance. This balance of sag resistance and leveling is highly desired, especially in semigloss and gloss paints that are applied by brush to doors, trims, window frames, etc.

Improved Color Acceptance and Color Rub Up

Color issues are among the most frequent consumer complaints. It is vital that rheology modifiers promote consistent color development regardless of application method, pigment chemistry or surfactant influence. The new rheology modifiers were specially designed to give superior color acceptance and to reduce color rub up across all pigments.

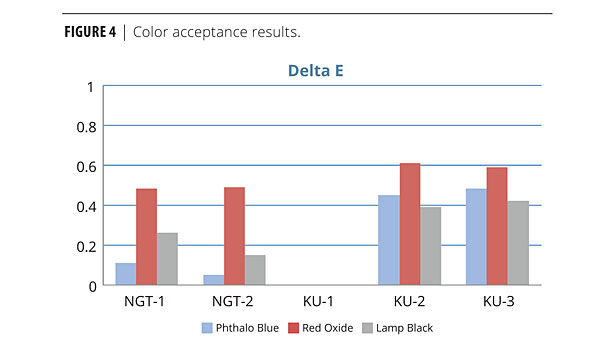

In the color acceptance chart illustrated in Figure 4, KU-1 thickener was used as the standard against which the other rheology modifiers were compared. Note that the new-generation zero-VOC thickeners showed substantially better color acceptance, while competing rheology modifiers deviated significantly from the control.

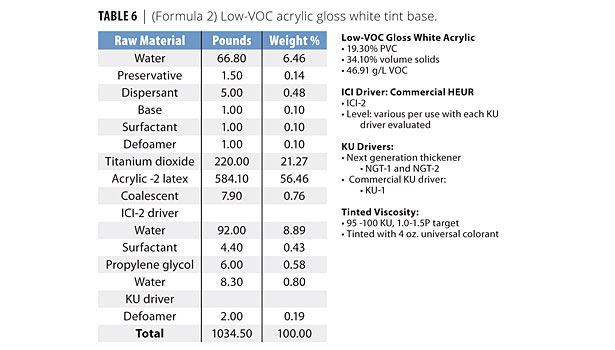

Formula 2: Low-VOC Acrylic Gloss White Tint Base

Rheology modifiers NGT-1 and NGT-2 were evaluated versus a commercial KU builder; KU-1 in a low-VOC acrylic gloss white tint base paint formula (Table 6). A commercial HEUR-type high-shear viscosity builder, ICI-2, was used in combination with all the different NGT and KU thickeners tested in this study. Rheology modifier levels were adjusted to achieve a tinted viscosity target of 95 - 100 KU and 1.0 - 1.5 ICI. The white base was tinted with 4 oz. of universal colorant. Colors evaluated in this study were phthalo blue, lamp black and red oxide.

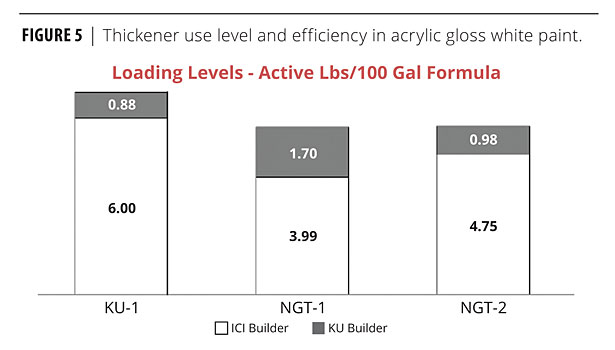

In terms of total active thickener, the new zero-VOC thickeners provide up to 15%-20% more efficient thickening. NGT-1 provides efficient KU build but less ICI contribution compared to NGT-2. In this case, the additional ICI contribution from NGT-2 reduced the overall use levels (Figure 5).

The NGT thickeners showed comparable performance properties compared to the commercial KU-1 thickener and helped to lower the overall VOC of the paint formula (Table 7).

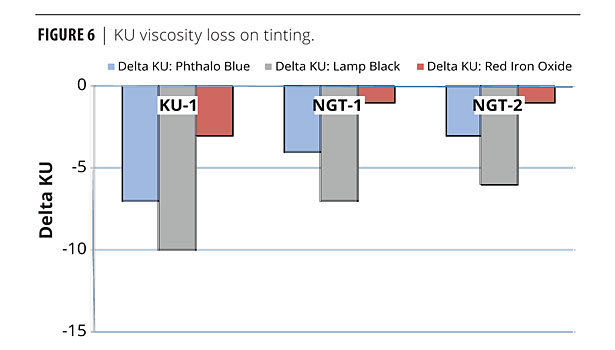

They also show better mid shear (KU) viscosity stability upon addition of colorants when compared to the competitive product (Figure 6)

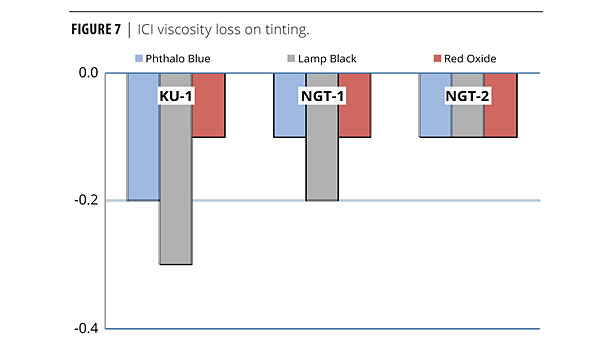

The thickeners also show better high-shear (ICI) viscosity stability upon addition of colorants when compared to the competitive product (Figure 7).

Superior Balance of Sag Resistance, and Flow and Leveling

As shown in Figures 8a and 8b, the NGT zero-VOC thickeners not only provide excellent sag resistance on tinting due to superior viscosity stability, they also improve brush leveling compared to the traditional associative thickeners.

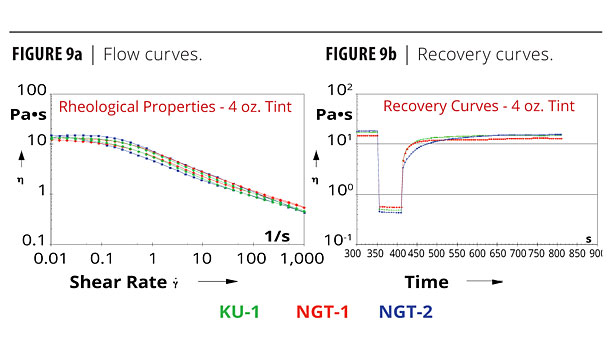

As mentioned earlier, the structures of the NGT zero-VOC thickeners are designed to regain their viscosity slightly more slowly after shearing than traditional thickeners (as shown in the flow and recovery curves Figures 9a and 9b). This results in superior leveling while maintaining excellent sag resistance. This balance of sag resistance and leveling is highly desired, especially in semigloss and gloss paints that are applied by brush to doors, trims, window frames, etc.

Improved Color Acceptance and Color Rub Up

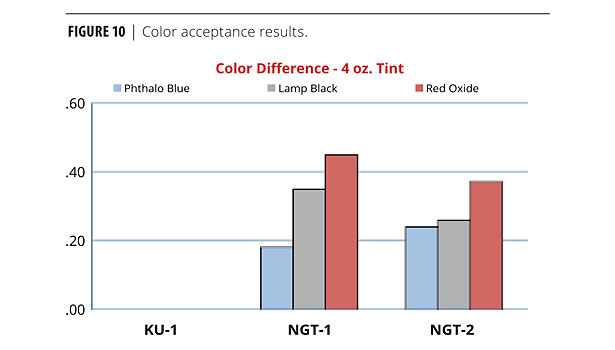

In the color acceptance chart (Figure 10), KU-1 thickener was used as the standard against which the other rheology modifiers were compared. The new-generation zero-VOC thickeners showed good color acceptance.

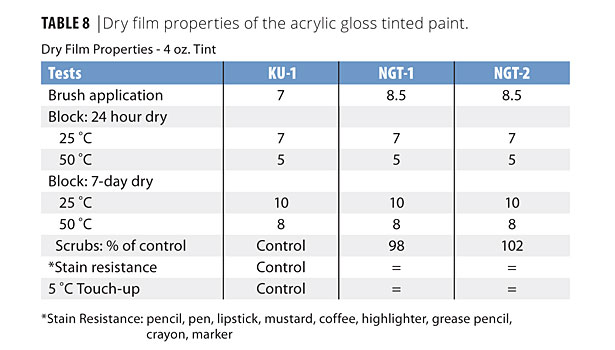

Dry Film Properties

As shown in Table 8, the overall dry film properties of the NGT zero-VOC-thickened paints were comparable to the commercial KU-1. The NGT thickeners however did show improvements in brush application.

Summary

The zero-VOC new-generation rheology modifiers provide paint formulators a high degree of freedom to develop new low- and zero-VOC formulations as well as reformulate existing products. The new rheology modifiers impart paints with a superior balance of sag resistance and leveling, minimized viscosity loss on tinting, and excellent color acceptance properties. The new rheology modifiers are efficient as well as easy to use in a broad range of binders.

References

1. Skeist Incorporated, Coatings, VII “Cellulose Ethers”, October, 2004.

2. Blake, D. M. “Thickeners for Waterborne Coatings”, Handbook of Coatings Additives, 1984.

3. Padget, J.C. Additives for Water-based Coatings, pp.1-11, 1988.

4. Elementis Specialties, “Rheology Handbook: 30th Edition”, pp.14-16, 2008.

5. Holmberg, K. “Introductions to Surfactants”, Surfactants and Aqueous Polymers in Aqueous Solution”, 2003.

6. Paczkowski, M and Wehrens, H, Associative Thickeners and Point of Sale Colorants: Can They Get Along? Paint and Coatings Industry, Vol. 23, April, 2007.

This article is based on a presentation given at the 12th International Coatings Congress at ABRAFATI 2011, Sao Paulo, Brazil.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!