The Need for Speed

The Wood Connection (TWC) in San Jose, Calif., is a custom cabinet shop that works with contractors and custom cabinet manufacturers. For years, its small ¼-inch diaphragm pump and high-volume, low-pressure (HVLP) gun provided the necessary platform to continually provide a flawless finish and contribute to the company's reputation for quality.

As is often the case, however, success can breed a host of new problems. TWC's commitment to quality led to an increase in business, which, in turn, affected the efficiency of its finishing operation. The company found that the speed of delivery that the existing pump/gun combination provided for its old usage of 25 gallons of spray each week no longer served its needs. The added business led to more work hours, since the pump could not meet the new demand in a standard work week, even when operating at full capacity. The required additional labor threatened to adversely affect TWC's bottom line; despite the increased business, the company faced a decreasing profit per unit. To solve the problem, TWC knew it needed to upgrade its finishing process.

Different levels of spray gun and pump technology exist, and each is designed to provide the best finish in the most cost-effective manner. The application and volume typically determine the best fit. The application technique (spray gun) drives the fluid delivery equipment requirements (pumps or tanks). TWC evaluated several types of spray guns and corresponding pumps when considering its upgrade.

Conventional Air Spray Guns

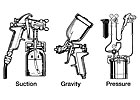

Conventional air spray guns offer the best overall surface finish and are probably the easiest to use correctly. They provide a low transfer efficiency compared to other techniques, such as HVLP and air assisted airless, but they serve the needs of many small shops and are still an efficient method of finishing for many applications. Just like the trusty screwdriver in every worker's toolbox, these spray guns are often maintained by shops that have migrated to more sophisticated tools and are used on smaller applications, special detail work or last-minute touchups.The three types of conventional fluid-feed, air spray guns - suction, gravity and pressure - generally have a simple design, are easy to use and provide a cost-effective finishing method (see Figure 1, p. 16). The suction spray gun is the most basic type and will spray thin materials only. This gun's fluid cup is typically small and needs refilling often, so the gun is limited to small-throughput applications. Additionally, this gun's cup can't be turned upside down, so it is not suitable for finishing products that require hard-to-reach areas, such as recessed cabinetry. The suction spray gun is ideal for small finishing shops that spray a maximum of two quarts of material in a session.

The gravity gun is easier to clean and offers superior atomization and less overspray than the suction gun, offering better overall performance. However, like the suction spray gun, the gravity gun's cup can't be inverted for recessed-area finishing.

The pressure-fed spray gun atomizes well and minimizes overspray, and can be used at any angle. Unlike a siphon or gravity-fed gun, the pressure-fed gun is typically connected to a pump or a pressure tank with a fluid hose. Its advantages over the suction and gravity guns include easier finishing for hard-to-reach areas and fewer trips to refill the finishing material. Pressure-fed guns are well suited for thicker coatings, higher throughput applications and hard-to-reach areas.

Figure 1. Conventional air spray guns include suction, gravity and pressure types.

HVLP Spray Guns

HVLP spray guns offer increased transfer efficiency over conventional air spray types, as well as a high-quality surface finish. They can dramatically improve finishing efficiency by using a higher volume of lower velocity atomizing air (compared to conventional spray guns). The increased transfer efficiency of HVLP guns enables them to minimize overspray, wasted material, booth filter use and booth maintenance. The guns' transfer efficiency can approach 60 percent, compared to conventional guns that only reach 30 percent in best-case circumstances (see Figure 2, p. 18). This increased efficiency also translates into fewer trips to the "paint locker."Most HVLP guns are in a gravity- or pressure-fed configuration. For pressure-fed configurations, a pressure tank or diaphragm pump is used to deliver coating to the gun.

As small shops grow and face increased regulatory scrutiny relating to volatile organic compound (VOC) emissions, or seek to reduce waste through increased transfer efficiency, HVLP guns present a viable upgrade from conventional air spray guns.

Air Assisted Airless Spray Guns

Air assisted airless spray guns offer speed and transfer efficiency benefits. Often an HVLP user will upgrade to air assisted airless because the transfer efficiencies are comparable, yet more material can be applied in a given amount of time. Air assisted airless guns are always pressure fed, so hard-to-reach areas can be accessed by inverting the gun. The guns' high transfer efficiency allows less material to find its way into the booth areas, resulting in decreased coating and filter usage, less booth maintenance and fewer trips to the "paint locker."Air assisted airless spray guns use a small tip in the gun and high fluid pressures to atomize the coating. The high pressures require different fluid delivery equipment than that normally found with conventional air spray or HVLP. A high-ratio piston pump is usually the equipment of choice.

Figure 2. HVLP and air assisted airless spray guns provide higher transfer efficiencies compared to conventional air spray guns.

Optimized Speed and Transfer Efficiency

After carefully evaluating the different options, The Wood Connection chose an air assisted airless spray gun combined with an 18:1 ratio air-driven piston pump (the Comet 3-B Outfit, supplied by ITW/Binks) to handle its new level of spray finishing demands. The new spray gun/pump combination has provided the required speed to help the company keep up with business growth. TWC has also benefited from the gun's minimized overspray, which has led to minimized waste, less booth filter usage, reduced booth maintenance and fewer trips to refill coating reservoirs.In short, the new finishing system allowed TWC to maintain quality, increase production and save money. Another added benefit is the positive work environment created when finishers can expect to produce a quality product and meet their production schedules.

Maximizing Piston Pump Efficiency:

Extending the Life of Your InvestmentIf air assisted airless is the right finishing technique for your operation, there's no way around it - you're going to need a piston pump to pressure feed your gun. However, a piston pump adds complexity over a simple cup of material attached to the gun. Following are some guidelines for selecting and maintaining piston pump equipment:

- Select the pump that delivers your material at less than its rated flow rate. Doubling the run speed can cause an eight-fold increase on pump wear. Pumps that run no more than 25 percent of maximum flow, or less than 15 cycles per minute, simply last longer. Just as you'd never drive your car at its maximum speed, so should you never push a pump to its full flow rate.

- Select a pump that can run your applications between 30 and 70 percent of its maximum delivery pressures and maintain that pressure. Running the pump at too high a pressure subjects your air motor and seals to friction and increased wear. Keeping the pressure at a lower level allows the air motor to perform quickly and efficiently.

- Use bigger, slower pumps for abrasive materials. While a stain, which is less abrasive, might run problem-free through a pump, the same pump filled with a more abrasive material, such as latex, military coatings, or zinc-laden primers, might need to run more slowly to avoid wear and premature failure.

- Use chevron seals when working with abrasive or varied materials. A U-cup seal will provide longer life with most coatings, but a chevron seal is more forgiving for applications that involve abrasive materials. A chevron seal will also allow you to fine-tune the amount of compression on the packings to extend the life of the pump even further.

- Never "dry-run" the pump. Simply checking to make sure the finishing material doesn't run out while the pump is operating will help maintain the equipment. Because the coating itself acts as a coolant, it wicks heat from the seal and pump interface, protecting them from heat and erosion.

- Periodically check for adequate solvent in the solvent cup. The solvent cup cleans and lubricates the piston rod. Allowing the cup to run dry will reduce the life of the pump's fluid section.

- Periodically check the pump's stroke rate. As a rule, the rise and fall rates of most pumps should remain even. An uneven stroke rate usually signals a problem.

- Use clean and dry compressed air. Dirty and humid compressed air reduces the life of the air motor and leads to increased maintenance cost. Using a simple filter/regulator is one of the most cost-effective ways to extend your equipment's life.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!