Control of the paint application process and assessment of paint quality requires sampling and monitoring key process output parameters such as coating thickness, color and appearance. Traditionally, measurements of thickness and color have been obtained using hand-held measurement gauges. Manual thickness and color measurement devices provide a means of conveniently making measurements virtually anywhere in a paint facility or even in the field. However, in industries where the parts or products being coated are large and/or the volumes are high, measurement of process output with manual gauges can be labor and time intensive.

In an automotive assembly plant, it is necessary to obtain measurements of the process output for a number of colors, body styles and paint application booths. With manual measurement gauges, it may only be feasible to measure the process output for a few color and body style combinations per operating shift. Therefore, it may take a number of days before every combination of color, body style and booth can be sampled.

An online automated measurement system can make it possible to significantly increase the rate at which samples of the paint process output can be obtained, especially for different combinations of colors, parts or body styles, and paint application booths. This dramatic increase in sample size along with a corresponding reduction in measurement time lag can lead to a significant improvement in control and optimization of the paint application process and facilitate troubleshooting of process problems. In turn, improved control over the process will provide benefits such as enhanced paint quality and reductions in both material usage and environmental emissions.

In addition to reducing time lag in obtaining paint process measurement feedback, there are other advantages to utilizing an automatic online measurement system. As an example, obtaining accurate and repeatable measurements from curved surfaces can sometimes be challenging when using a contacting hand held spectrophotometer.

A robotic measurement system also provides a significant labor savings. It will no longer be necessary to allocate labor for the operation and collection of measurement data from hand held gauges. Furthermore, robotic measurements will be more repeatable because the robotically manipulated measurement gauge sensors are placed in precisely the same locations part after part.

In an automotive paint facility application, a typical cell will contain two robots, one on each side of the vehicle. When each robot has both an ultrasonic multi-layer thickness gauge and a multi-angle spectrophotometer, the cell will be able to obtain 50 multi-layer thickness measurements at various locations along with a color measurement in the center of each body panel in approximately 6 minutes. With this cycle time, multi-layer film thickness and color measurements can be obtained from approximately seven jobs per hour.

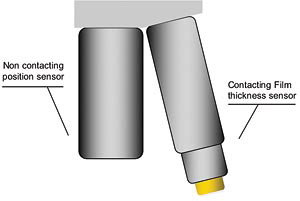

In the case of robotic multi-layer ultrasonic thickness gauging, measurements are obtained by the use of non-contacting position sensors and a special contacting ultrasonic sensor. Because active non-contact positioning is used, the programmed angle and distance to the body surface are not critical and there is an allowance for some angular and positional variability from part to part or job to job. The contacting ultrasonic thickness gauging sensor will obtain multi-layer measurements on virtually any substrate material - steel, aluminum, SMC, and plastics.

For robotic multi-angle spectrophotometer measurements, the robot is once again moved to a rough programmed position approximately 100 mm above the painted surface. A combination of ultrasonic and infrared positioning sensors provide the robot with the information required to move to a final measurement position 35 mm from the body surface. Once in final position, the spectrophotometer obtains color measurements at four different angles, and it can also obtain surface temperature and orange peel data.

Sam Rosenberg is program manager for robotic PELT systems at JSR Ultrasonics, Pittsford, N.Y. Call 585-264-0480, or visit www.jsrultrasonics.com.

David Adkins is sales engineer, non-contact systems, at X-Rite, Grandville, Mich. Call 616-257-2170, or visit www.xrite.com.