Electrostatics: Better Understanding for Better Results

Although many key people in control of coating application lines understand the concept of electrostatic applications, they fail to recognize its weak links. In fact, two very important factors with which coating application people identify, but do not fully understand the actual significance of, are part-to-earth ground and manual operator isolation.

These two factors alone account for the majority of complaints about application lines. Some of these complaints may already be familiar:

- Coating inconsistency from part to part/rack to rack/day to day

- Excessive material usage or fluctuation

- Excessive overspray on equipment or manual spray application personnel

- Increased housekeeping time/booth filter usage

- Need to continuously adjust controls (also pertains to consistency)

- Fire hazards (flash fires/booth fires)

- Shocks to manual spray application personnel

- Inability of manual spray application personnel to keep up with line speed

- Excessive fumes

Part to ground

A high percentage of issues on the coating application line are due in part to the grounding condition. Even under the best circumstances and after following the best procedures, this condition can be the cause of many problems on the application line. It may be due, in part, to the misunderstanding of the true importance of grounding of the product to be sprayed. Or, perhaps it is the end result of not properly following procedures to maintain the ground over time.The poor grounding condition may also be identified with further signs of:

- Crackling noises or sparking from the parts and/or racks as they enter/exit the spray booth with the electrostatics activated.

- Checking the part for ground with a MegOhm meter produces readings that vary from no reading to good positive reading to negative reading, while the part enters the booth with the electrostatics enabled (earth ground is always a positive reading). Ideal readings are less than one MegOhm of resistance.

- Micro amp reading on meter of power unit operates higher than typically observed in the past.

When clean, the hanger or rack attracts as much (if not more) material to it (and not to the part) due to its size and location in relation to the parts and application device. Gradually, as the parts hanger and racks repeatedly go through the system, they eventually accumulate material (photo, left).

In actuality, this is a good thing-provided the contact points remain clean for a good ground to part. This relates to the insulation factor of the rack, allowing more material to be attracted to the part, not the rack. Once the hanger or rack accumulates material to a point that contamination could occur, it should be cleaned.

The contact point of the part to rack, or hanger relationship, is critical (photo, next page). If the hanging arrangement of the part(s) is such that a partial rack is loaded and the contact points are not masked or a part falls off prior to the material application station and the contact points become coated, proper grounding can be compromised.

Since this is a gradual process, most application system operators may make slight adjustments to compensate. And they may do so without a thorough understanding of what the underlining reason, or reasons, may be for making such adjustments. After time, the system operator may realize that the revised parameters are quite different from the original, established parameters. Or possibly, the QA department or line supervisor has informed the operator that the product does not meet required specifications.

At this stage, questions arise as to the possible cause, or causes, for the inconsistency. Operator errors, equipment failure or coating material formulations are just a few of the fundamental sources examined. Oftentimes, even after these sources are scrutinized and changes are made, the application process still does not improve and, in certain instances, produces results of poorer quality.

How poor ground impacts quality

To better understand the importance of poor ground as the probable source for these application or quality issues, several significant questions arise:- Does the conveyor system have a means of a solid earth ground connection at or close to the point of entry to the electrostatic spray booth? (This is accomplished by connection of a grounding rod or solid connection to a metal structure with positive earth ground.)

- Is a technique in place to periodically check the parts and racks for an earth ground prior to entering the electrostatic spray booth?

- Do the rollers on the conveyor contain conductive grease? Are the conveyor rollers in contact with the rail while traveling through the electrostatic spray booth? If not, a friction device that has a genuine earth ground can be used to ensure a reliable earth ground.

- Does the conveyor chain include a cleaning method (motorized cleaning brushes, in-line fixed brushes, high pressure washer, periodical removal of cleaning or replacement of chain)?

- Are the part hangers and/or rack contact points/connections kept out of the spray area or masked? Or is a repulsion type of tool used to prevent these areas from becoming coated with material? Is there a cleaning method in place for the parts hangers or racks?

If the parts to be coated enter the electrostatic spray application area in a poorly grounded (or ungrounded) condition, several distinct results can occur, including:

1. Parts will not attract charged particles of coating material efficiently, resulting in light coverage.

2. Parts will become capacitors retaining some degree of the negative charge (how isolated the parts are will determine the level retained). This condition will result in two major considerations: Parts will actually begin to repel charged particles of coating, and the charged state of the parts could result in an electrical discharge great enough to initiate a fire under certain conditions.

3. Charged coating material will seek out the nearest ground and adhere to it (booth walls, equipment and floor).

4. The electrostatic system will become overworked and could fail prematurely.

Isolating application personnel

Manual spray gun operator isolation can also be a source of concern, especially as it pertains to operator welfare. There are documented instances in which operator isolation has been a contributing factor in the cause of plant fires, personal injuries and even deaths. These occurrences have been due, in part, to the misunderstanding of electrostatics' importance in relation to grounding. However, as long as good grounding practices are followed, electrostatic applications are quite safe. Proper understanding of just how isolation from grounding relates to the human body is key to putting the practice into action.On a day with very low humidity, just about everyone at one time or another has, after walking across a carpeted floor, received a shock after touching metal, such as a door knob, light switch or refrigerator door. Or upon exiting a car, received a shock after touching the car door handle or metal part of the car.

This is caused by a static electric charge becoming stored in the human body, which is more than 72% water (and water is an excellent electrical conductor). When the human body is not grounded, it functions as an electrical capacitor, storing the electrical charge until it can find a grounded source to discharge this stored energy. That is the shock that's felt. The stronger the charge, the greater the shock.

That same condition can relate to an electrostatic spray booth and an isolated manual spray gun operator, or anyone in the booth. If an operator is not grounded in the spray booth while the electrostatics is operating, the human body begins storing the electric charge. When the painter nears a ground source, the stored charge dissipates.

The strength of the electrostatically charged field and length of time the painter spends in the charged field affect the amount of stored charge. When a charge dissipates in a volatile atmosphere in the form of a spark, a fire can occur. In many cases, this would be a flash fire, but under the right conditions, a major fire can result, producing significant damage to persons and/or property.

Proper grounding

To ensure that a manual spray gun operator is properly grounded, the available sources of proper grounding must be examined:The spray gun-Is the spray gun properly grounded by method of a grounded fluid hose, grounded air hose or electrical wire connection? With most electrostatic hand spray guns, the gun handle is manufactured to ensure that the operator is grounded, provided that the hand spray gun is properly grounded and handled correctly.

In many businesses, the introduction of airborne or handling contaminates, such as clothing fibers, hair, dirt, skin oils, sweat, deodorants and perfumes, will determine if gloves, boots, Tyvek suits, or other protection measures are used to control or remove these contaminates from the paint booth. Of all the contaminate defense tools utilized, the gloves are the most overlooked regarding improper spray gun grounding.

Gloves-The glove used by the operator is a major contributor to improper grounding. Typically, gloves are primarily used to protect an operator's hands from spray contamination and protect the part to be coated from foreign matter (perspiration, clothing fibers, skin oils and hair). However, what many hand spray operators do not understand is that gloves can also prevent operators from obtaining an appropriate ground through the spray gun's handle and protection from a possible shock hazard.

Positioning the hand as if handling a spray gun forms a curvature in the palm that, at times, prevents firm contact with the gun handle. A better method to assure a ground is to remove an area of the glove at the fingers that trigger the spray gun. The entire finger portion of the glove need not be removed, only a portion to assure a good ground while triggering the gun.

Use of a grounding strap is another way to ground the operator. However, this method works only if the operator is required to make limited movements.

Operator footwear-Occasionally, footwear is required as protection from spray contamination to the hand spray operator or possible foreign matter contamination on the parts currently being coated. Various types of protective footwear are utilized, such as rubber boots, Tyvek booties and rubber-soled work shoes. Although the footwear is not typically considered an issue in proper operator grounding, it may be a contributing factor in the grounding isolation of a hand spray operator and should be regarded as an obstruction to ensuring a safely grounded hand spray operator.

When the movements of the hand spray operator are limited, a static strap can be used to make certain the hand spray operator is properly grounded.

A solid step

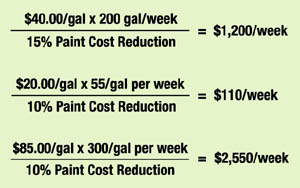

Use of electrostatic application technology is a strong, solid step toward maximum transfer efficiency. And because coating materials costs vary widely, any improvement to transfer efficiency will have a positive impact on the coating operation's bottom line.In general, projected savings from proper grounding can be estimated by reviewing the specifics of a coating operation (Figure 1).

What if grounding conditions played a smaller or larger role in your coating operations than shown in Figure 1? A variance of as little as 5% or as large as 25% of dollars saved or wasted adds up quickly. And, when you factor in material costs increases, the full impact of how grounding plays a key role in any coating operation is clear.

In addition to proper ground, there are many ways to improve the transfer efficiency of a coatings application line. They include climate control, increase/decrease of coating material conductivity, booth air flow controls, and paint repulsion bars. However, a good ground will continuously assure continuity of coating material to product for maximum transfer efficiency and optimum finish quality.

A better understanding of how electrostatics work is a very important aspect of increasing transfer efficiency, achieving better parts coverage, improving finish quality in coating application lines, and personal safety.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!