Low-Odor, VOC-Free Renewable Coalescents for Latexes Used in Very Low-VOC Paints

Two of the most important contributors to VOCs in low-VOC paints are ethylene or propylene glycol and coalescents. We have found that specific high-purity esters of fatty acids and their blends can be utilized to provide very low-odor, VOC-free, renewable coalescents to enhance the performance of latexes used in low-VOC paints.

Consumers today are more aware of health hazards and the environmental impact associated with the solvents used in paints and other household cleaning products. Sustainability has become an increasingly important factor for coatings and inks, which consume about 50% of all organic solvents manufactured for industrial applications globally. As a result, raw material suppliers need ecologically sound solutions that offer greater end user appeal while complying with the ever-more-stringent environmental legislation and consumer demands. Sustainability and wellness are key drivers of innovation, as manufacturers seek to meet consumer need for low-odor and non-toxic products. At the same time, coatings producers are looking for reduction in raw material cost and expect additive solutions that offer multiple performance benefits and are suitable for a variety of applications.

Key Challenges: Regulatory Compliance and Consumer Preferences

One of the most relevant developments in the consumer coatings market relates to the use of VOCs, often referred to as the “Achilles heel” of the coatings industry. VOCs in paint migrate from the film and evaporate into the atmosphere where they react with nitrogen oxide compounds to form pollutants including but not limited to low-level ozone. Pollutants are a major component of smog causing negative health and environmental impacts. Thus their reduction has become a major objective of environmental legislation.The definition of a VOC differs from region to region. For example, in the United States, VOC is measured by EPA Method 24 and is any organic material that volatilizes when subjected to 110 °C for one hour. However, in Europe any solvent whose vapor pressure at 20 °C exceeds 0.01 kPa and any organic material whose boiling point is less than 250 °C is considered to be a VOC. The European Union’s proposed decorative paint directive will set strict limits on VOCs in ready-for-use paints. In the United States, some of the more densely populated eastern states have regulations that limit VOC to 100 g/L in flat paints and 150 g/L in non-flat paints. In California, restrictions limit VOC content to 50 g/L for paints.

On the other hand, consumers are increasingly concerned with odors and toxicity of volatiles from paints. Odors that linger for many days after a paint is applied indoors are becoming a global consumer concern (results of Cognis global survey).1

Coalescents - Contributors to VOCs

There are many ingredients in a paint that can contribute to VOCs. Coalescing agents are one of the major contributors to VOC in water-based coatings. Coalescents are used for film formation. After the paint is applied and water evaporates, the film is formed by fusion of individual latex particles; the quality of the resulting film is a decisive factor in many aspects of the paint’s performance (Figure 1). The greater the integrity of the polymer film, the better the scrub resistance, dirt pick-up resistance and gloss. The optimum level of coalescents must be used in order to achieve good film formation at the lowest intended application temperature. To determine this level, a series of coalescent concentrations, calculated based on latex solids content, are tested on a Minimum Film Formation Temperature (MFFT) bar.Other major VOC contributors are glycols, which are generally added to improve open time and freeze-thaw resistance during storage and to improve wet edge time during paint application. Other additives such as dispersants, surfactants, rheology modifiers and biocides are minor but significant contributors to VOCs.

Hence, the stringent restrictions on the use of VOC-containing raw materials have forced decorative paint formulators to seek new solutions that allow them the flexibility of developing products that comply with new regulations without impacting application and film properties.

Market-Oriented Solutions

In order to meet diverse market challenges, coating manufacturers need to balance technical knowledge and formulation requirements against optimized cost levels and performance. At the same time, they are forced to seek unique, technologically innovative solutions rather than always having to rely on the traditional products currently available on the market. Such innovative solutions must combine superior performance, sustainability and convenience with reduced formulated costs and performance that meets or exceeds the end user’s expectations.

Emission-Free Coalescents (EFCs)

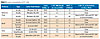

Three years ago, a high-purity version of propylene glycol mono-oleate (EFC 100 = Loxanol EFC 100) based on renewable oleic acid was introduced to meet stringent VOC requirements in the global consumer coatings market. Based on customer feedback, a second-generation propylene glycol monoester with C-18 fatty acid mixtures (EFC 200 = Loxanol EFC 200) has recently been introduced that has better color and offers an improved value. A third product based on renewable technology is a high-purity version of linear short chain fatty esters (EFC 300 = Loxanol EFC 300), which is VOC-free based on the European definition but is over 90% VOC by EPA Method 24. EFC 300 is over 30% more efficient than trimethyl pentanediol monoisobutyrate ester (TMB) in many popular types of latexes and offers improved hardness development and dirt-pick-up resistance. EFC 200 and EFC 300 are naturally derived, low-odor coalescing agents and can be used in all types of decorative paints. They improve performance and application properties while helping to achieve compliance with new VOC regulations. These two coalescents are registered in several countries around the world. Key properties of the two new coalescing agents are summarized in Table 1.

Latex Compatibility and MFFT Reduction Efficiency

EFC 200We have evaluated compatibility and MMFT reduction of various commercial latexes with EFC 200; results are summarized in Table 2.

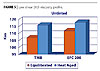

EFC 100 and EFC 200 are mainly designed to fulfill EPA 24 VOC Method, whereas EFC 300 is designed for all other applications. Table 3 shows the testing and results of the EFC 300 in various commercial latexes in comparison to TMB. In many cases, one needs to use one third less EFC 300 and the hardness development is superior due to improved release from the drying paint film.

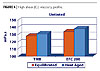

Achieving Regulatory Compliance with Sustainable Ingredients

EFC-200 is based on renewable C-18 fatty acids and significantly reduces VOC emissions from architectural paints. One way to measure VOC emission is to calculate the amount that each ingredient contributes to the total. The sum of each ingredient’s contribution is the calculated VOC of the system. Another method is “EPA Method 24”. Here, the volatile content of the test material is measured after being heated at 110 °C for one hour in a forced air oven. The industry-standard coalescing agent, TMB, has a VOC content of 100% when tested under these conditions. Using this same test, the VOC content of EFC-200 is approximately 2% (Figure 2).

Meeting Performance Requirements

We evaluated EFC 200 and compared its performance properties against industry-standard coalescent TMB in exterior as well as interior paint formulations (Tables 4 and 5).

Rheology Performance

The study demonstrated that the use of EFC 200 coalescent offers more efficient rheology modification than TMB, at both high (ICI) and low (KU) shear rates (Figures 4 and 5).

Gloss Improvement

The study also showed that EFC-200 provides better flow and leveling than TMB, without compromising sag resistance. Another benefit was seen in the gloss of the paint finishes, which was improved remarkably in tests at both 20° and 60° angles, due to the improved film coalescence. Moreover, this improved gloss is also displayed at lower temperatures (5 °C) as shown in Figure 6. An additional finding was that gloss in high PVC flat paints is unaffected by the switch from TMB to EFC 200.

Scrub Resistance

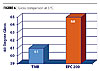

EFC-200 also offers significantly improved scrub resistance by as much as 20% in comparison to the TMB control interior paint sample, providing further evidence of its advanced coalescence (Figure 7).Conclusion

We found that specific high-purity esters of fatty acids and their blends can be utilized to provide very low-odor, VOC-free, renewable coalescents to enhance the performance of latexes used in low-VOC paints. It is possible to have significant performance improvements with regard to hardness development and dirt-pick-up resistance with EFC 300 when EPA Method 24 VOC-free technology is not a must but increased use of renewable technology with low odor is the goal. EFC 200 is the product of choice when VOC elimination under the toughest global regulations is the goal; TMB odor elimination and renewable aspects are the desired bonuses. Other side benefits of this renewable technology have been demonstrated to be improved rheology efficiency, gloss enhancement and scrub resistance.This paper was presented at the American Coatings Conference, Charlotte, NC, June, 2008.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

Article pictures/tables to small

August 20, 2020

The tables in this article are too small to read, and they don't enlarge.

Tables and Figures

August 20, 2020

Yes, when we converted to our new web platform, not all of our older articles switched over correctly. I will try to locate the pdf for you and email it.

VOC Free Coalescents

August 17, 2022

Cai i get link for this paper? THis will help me in study full details.