New Facility Confirms Dow's Commitment to Latex Industry

After the completion of Dow Chemical Company’s acquisition of Union Carbide Corporation in early 2001, Dow had to make some strategic decisions regarding its role in the emulsions arena. Customers of UCAR Emulsion Systems (UES), a wholly owned subsidiary of Dow, asked the company to increase the breadth, depth and flexibility of its product offering, and needed Dow to demonstrate its commitment to the industry.

After the completion of Dow Chemical Company’s acquisition of Union Carbide Corporation in early 2001, Dow had to make some strategic decisions regarding its role in the emulsions arena. Customers of UCAR Emulsion Systems (UES), a wholly owned subsidiary of Dow, asked the company to increase the breadth, depth and flexibility of its product offering, and needed Dow to demonstrate its commitment to the industry.

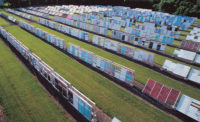

Dow’s UCAR Emulsion Systems confirmed its desire to be a player for the long haul with the announcement in February 2004 of its plans to invest in its North American manufacturing capability. This plan included construction of a new latex facility at Union Carbide Corporation’s St. Charles Operations in Louisiana. The new facility represents a significant investment in UES by Dow and the Union Carbide Corporation, and is the primary portion of the companies’ multi-year, $100 MM staged investment plan in North American operations. It is the first grass-roots latex facility to be built in the United States in 30 years.

“Having a solid base of loyal customers who recognize the value in our products was a key factor in our decision to move forward with this project,” noted Thayne Hansen, UES business director. “This new facility reflects our commitment to invest in production assets that match customer, community and North American needs for the next 20 years,” Hansen added. “We are excited about working with our customers to capture the expanded production and process technology benefits embedded in this new plant. St. Charles operations reflects our continued commitment to latex applications.”

In February 2006, UES announced the successful start-up of its next-generation latex facility. Every aspect of the new facility’s operation, including the process, environmental controls, quality and worker safety, sets a new level of standards for latex plants worldwide.

Dow chose the site in Louisiana for several reasons - abundant natural resources, the excellent transportation network and deepwater ports, access to the Mississippi River, available land and a dedicated workforce. It is a long-term, sustainable Dow site, with room to grow. It also is located in a “chemical corridor,” away from communities that would frown upon a chemical plant in the neighborhood.

The plant has many systems in place to ensure this consistency. Over 3,000 instruments monitor the plant. When raw materials are received at the site, they are scanned with an FT-IR spectrophotometer to make sure that the material in the package is in fact the same as the label indicates.

A novel bar coding system has also been implemented to help keep track of the 100 raw materials at the site. Each raw material is bar coded to ensure that the right product is being used. Initially a safety feature to prevent the mixing of the wrong chemicals, it offers other benefits as well in terms of quality control and waste management.

In the lab, samples are tested throughout all phases of manufacture. Samples are also taken from each batch as it is being loaded for shipment and kept for reference in case the customer ever needs to refer to it.

After the completion of Dow Chemical Company’s acquisition of Union Carbide Corporation in early 2001, Dow had to make some strategic decisions regarding its role in the emulsions arena. Customers of UCAR Emulsion Systems (UES), a wholly owned subsidiary of Dow, asked the company to increase the breadth, depth and flexibility of its product offering, and needed Dow to demonstrate its commitment to the industry.

Dow’s UCAR Emulsion Systems confirmed its desire to be a player for the long haul with the announcement in February 2004 of its plans to invest in its North American manufacturing capability. This plan included construction of a new latex facility at Union Carbide Corporation’s St. Charles Operations in Louisiana. The new facility represents a significant investment in UES by Dow and the Union Carbide Corporation, and is the primary portion of the companies’ multi-year, $100 MM staged investment plan in North American operations. It is the first grass-roots latex facility to be built in the United States in 30 years.

“Having a solid base of loyal customers who recognize the value in our products was a key factor in our decision to move forward with this project,” noted Thayne Hansen, UES business director. “This new facility reflects our commitment to invest in production assets that match customer, community and North American needs for the next 20 years,” Hansen added. “We are excited about working with our customers to capture the expanded production and process technology benefits embedded in this new plant. St. Charles operations reflects our continued commitment to latex applications.”

In February 2006, UES announced the successful start-up of its next-generation latex facility. Every aspect of the new facility’s operation, including the process, environmental controls, quality and worker safety, sets a new level of standards for latex plants worldwide.

Dow in Louisiana

Dow is one of the largest petrochemical producers in Louisiana, with $8 billion in assets in the state. It has more than 6,000 employees and contract employees that safely manufacture more than 100 basic and specialty chemicals.Dow chose the site in Louisiana for several reasons - abundant natural resources, the excellent transportation network and deepwater ports, access to the Mississippi River, available land and a dedicated workforce. It is a long-term, sustainable Dow site, with room to grow. It also is located in a “chemical corridor,” away from communities that would frown upon a chemical plant in the neighborhood.

A Broad Selection of Binder Technology

One of the new technologies to come from this plant is the EVOCAR™ ethylene-modified polymer line. This new family of products promises to bring improved performance and value to a wide variety of applications. One example is in architectural coatings, where the company has been able to demonstrate improved durability and versatility in a variety of formulations. The EVOCAR line will also provide the capability to achieve low- or zero-VOC products to comply with environmental regulations. Among the performance strengths of architectural coatings based on these binders are improved scrub resistance, color development, low-temperature touch-up and anti-blocking properties.A Quality Process

In all of the products that the new facility produces, a manufacturing approach focused on quality is key. According to Michael Faulkner, production leader at the St. Charles facility, “Quality is all in the process.” For each batch, the goal is to add the right ingredients, in the right amounts, at the right time, and then process the batch the same way every time, using the same equipment, the same procedures, the same temperature, etc. This way, variation is controlled and the process is more capable. According to Faulkner, “Our aim is to be Six Sigma capable in order to be a Six Sigma supplier.”The plant has many systems in place to ensure this consistency. Over 3,000 instruments monitor the plant. When raw materials are received at the site, they are scanned with an FT-IR spectrophotometer to make sure that the material in the package is in fact the same as the label indicates.

A novel bar coding system has also been implemented to help keep track of the 100 raw materials at the site. Each raw material is bar coded to ensure that the right product is being used. Initially a safety feature to prevent the mixing of the wrong chemicals, it offers other benefits as well in terms of quality control and waste management.

In the lab, samples are tested throughout all phases of manufacture. Samples are also taken from each batch as it is being loaded for shipment and kept for reference in case the customer ever needs to refer to it.

A Commitment to the Coatings Industry

Although the startup of the new latex plant at St. Charles is an important milestone for both Dow’s UCAR Emulsion Systems and its customers, it is not the end of Dow’s commitment to building a better UES. The introduction of new products and technology platforms will continue to signal growth. As Thayne Hansen pointed out, “The St. Charles plant represents the cornerstone of future actions in support of our customers.”Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!