Nepheline Syenite for the Global Coatings Industry

Unimin Corporation, the world's leading producer of nepheline syenite, and its customers recently experienced such a supply dilemma. With the recent completion of a comprehensive, two-year expansion program, Unimin reports it has increased its MINEX® functional filler production capacity by 50% and is now well positioned to satisfy the growing market for this material.

So what exactly is nepheline syenite and why has demand for it increased so dramatically? To answer these questions, it is necessary to explore the mineralogy and performance attributes of this unique mineral.

Mineralogy and Applications

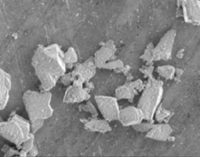

Nepheline syenite is an igneous rock formed from molten magma in a silica-deficient environment. With an appearance similar to granite, nepheline syenite is composed of three primary minerals: the albite form of feldspar, the microcline form of feldspar and nepheline. The percentages of each vary by deposit location, with a typical composition consisting of 54% albite, 24% microcline and 22% nepheline.The presence of nepheline and absence of crystalline silica is what differentiates this uniquely occurring rock from feldspar fillers containing just albite and microcline and from other commonly available silicate minerals such as clay, talc, wollastonite and mica. Mohs hardness on the 1 to 10 scale is about 6. Its low refractive index, in the range of 1.50 to 1.53, is nearly equivalent to several commercially significant polymer resins.

While there are considerable nepheline syenite deposits throughout the world, certain ore reserves are particularly well suited for processing and refinement as high-performance fillers. This is due to the unique geology of accessory minerals contained in these deposits, which allows for production of a pure, high-brightness admixture of feldspars and nepheline that is deficient in crystalline silica, iron and other impurities. These reserves are also distinguished by the consistency of their chemical composition, providing reliable and predictable performance for demanding applications. Products from these sources are sold by Unimin under the brand name MINEX for coating, elastomer, architectural paint and adhesive applications. Nepheline syenite is also valuable in other industries, such as glass manufacturing, where it contributes needed alkalis and alumina to the glass batch.

Performance Advantages

MINEX functional fillers derived from nepheline syenite have experienced strong demand growth in recent years. Broadly speaking, this increased demand can be attributed to two important characteristics: compatibility with environmental and industrial hygiene practices, and improved product performance.Frank Cangelosi, Unimin Marketing Manager for Functional Fillers and Extenders, explains,"The coatings industry is constantly being challenged to make our environment safer. Increasingly stringent environmental regulations globally are demanding changes in product formulation. Reduction or removal of organic solvents or VOCs in the last decade has been a primary focus, as allowable VOC levels in coatings continue to shrink. Advances in technologies such as waterborne, high-solids and powder coatings have helped meet tougher regulations and legislation."

"The surface chemistry of nepheline syenite is ideal for zero- or low-VOC systems. With a net negative surface charge, nepheline syenite accelerates dispersion times with little or no polymeric dispersant requirements. Low in oil absorption, with a typical range between 22 to 35 percent, nepheline syenite is effective in high-solids and powder coating applications where matting is desired and low viscosity must be maintained. Furthermore, due to its mineralogy, nepheline syenite is defined by geologists, testing laboratories and regulatory agencies as deficient in crystalline silica."

In terms of improved product performance, the select nepheline syenite deposits used in the production of MINEX functional fillers are documented as imparting surprising improvements in weatherability. Cangelosi notes, "It is hypothesized that its lower silica content acts as a photo-oxidative inhibitor to retard the formation of radicals that ultimately cause organic resins and binders to degrade upon exposure to sunlight or moisture." Other properties of this material, such as low oil absorption and high ultraviolet light transmission, contribute to analytically measured improvements in gloss retention, chalk resistance and color retention when incorporated as the filling or extending pigment. Typical data from outdoor weathering studies, indicative of this improved performance, are shown in Figures 1 and 2.

The low refractive index of nepheline syenite, being similar to several types of commonly used clear binders such as polyurethanes, epoxies, alkyds and nitrocellulose, also provides advantages. Cangelosi explains, "When the difference between pigment and binder refractive indices is less than 0.1, the result is transparency. Nepheline syenite can be added up to approximately 20% as a matting agent before causing noticeable haze. In addition, the mineral possesses ideal light-transmission properties in the UV range, enhancing cure performance for growing UV-curable coating applications."

In powder coatings, nepheline syenite offers superior flatting efficiency relative to barium sulfate and calcium carbonate, and improved pellet flow relative to wollastonite and talc because of its low oil absorption, ease of mixing and optimum particle shape. Slightly harder than wollastonite, it also improves scratch and abrasion resistance in appliance and office furniture applications. And, as noted earlier, the weathering properties of this material in outdoor applications, such as lawn furniture or garden equipment, are excellent.

Capacity Expansion

While the environmental and performance advantages of nepheline syenite are clear, these benefits are lost unless customers can be assured of a reliable, long-term supply. That's where recent Unimin investments to expand its functional fillers production capacity come into play."The convergence of environmental drivers, valuable performance benefits, and an unprecedented period of construction and renovation created an exceptionally strong demand for our nepheline syenite-based filler grades," explains Craig Johnson, Unimin's Director of Corporate Marketing. "We immediately recognized that new capacity would be needed, but long lead times for proprietary processing equipment and a rigorous quality auditing process delayed our ability to respond. I am pleased to report that our aggressive expansion program has exceeded our targeted capacity objectives."

Indeed, the company has invested millions of dollars to expand its global production capacity for nepheline syenite. Three new mills have been installed and, in combination with upgrades to existing facilities and delivery systems, Unimin has increased by 50% its production capabilities for its MINEX functional filler grades. Product from the new facilities has been thoroughly tested and is now being sold in the marketplace.

Looking to the Future

Perhaps most significant, additional expansions are planned, including a fourth mill, which is scheduled for start-up in early 2005. Johnson notes, "We are convinced that the recent surge in demand for nepheline syenite will continue, and are planning accordingly. The technical and regulatory drivers behind the market growth of these functional fillers are becoming the new industry standards. If anything, environmental considerations, including new low-VOC requirements and higher loading targets, and product labeling and workplace safety regulations, are likely to become more stringent. We also anticipate continued producer emphasis on product performance and color longevity. Our MINEX nepheline syenite grades are well positioned to address these customer needs.""With confidence in our ability to serve this important industry, Unimin can fully apply its research and development resources to the task of product refinement and new product development," says Johnson, "The company's greatest strength is its ability to work with our customers, to respond to their performance objectives and to optimize our nepheline syenite materials for the next generation of paint and coating products."

Johnson concludes, "With new and significant global delivery capacities, new products in the pipeline, and additional expansion plans in place, formulators can regard MINEX as a reliable tool to fulfill their present and future needs."

For more information, contact Unimin Corp., 258 Elm St., New Canaan, CT 06840; phone 618/747.2311; fax 618/747.9318; e-mail brilliantadditions@unimin.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!