Sol-Gel Hybrid Coatings for Wood Products with Improved Surface Durability and Repellence Properties

Wood and wood-based composites are widely used as construction, furnishing and decorating materials for ecological reasons and also because of the appealing appearance of wooden surfaces. However, due to its softness and water-absorbing nature, plain wood and wood composite surfaces are easily damaged by water and by mechanical abrasion. Wood products with improved surface properties can be achieved by using coating systems based on sol-gel hybrid concepts. By tailoring and optimizing the composition of the sol-gel, the properties of the thin coatings can be directed in the desired direction. Coatings systems consisting of a ceramic network and polymeric compounds have been developed in order to make transparent abrasive-resistant and water-repelling surfaces for wooden substrates.

Sol-gel hybrid coatings provide a new approach to improve surface properties of different materials. These coatings can be applied on metals, ceramics, glass, polymers, concrete and even on wood. Due to the inorganic components, the inorganic/organic hybrid coatings possess high thermal and mechanical stability, whereas the organic components are responsible for the flexibility and film-forming nature of the coatings. By tailoring the composition, thin hybrid coatings with high abrasion and scratch resistance can be created.1

Wood as a renewable and economical natural resource is one of the most important raw materials for a variety of furnishing and building applications. The appealing appearance and feel of wood and wood composite surfaces are most preferably protected with thin and transparent coatings that do not remarkably change the appearance of the substrate. A sol-gel technique enables formation of such coatings with a thickness of only a few microns. Sol-gel deposition has been successfully used to treat wood with alkoxysilanes in order to protect wood against weathering.2 In addition, sol-gel deposition of alkoxysilanes on wooden surfaces is suggested to result in a polysiloxane network that is covalently bonded to the substrate.2-4 Furthermore, treatment parameters, i.e., curing temperature of the coatings, can be adjusted so that no thermal degradation takes place in the substrate.

In this study, the performance of the hybrid thin coatings on pine and birch substrates was evaluated by means of surface characteristic measurements (e.g., surface energy, hydrophobicity, gloss, microscope evaluation on surface structure) prior to and after abrasion procedures.

Experimental

Pine and birch (Pinus sylvestris and Betula pendula) specimens [dimensions of 5 x 50 x 100 mm (radial x tangential x axial)] were used as substrates for three alkoxysilane-based sol-gel coatings referred to as PRO 1, 2 and 3. In addition to plain planed-wood surfaces, birch samples with acrylate lacquer surfaces were used as substrates for the coatings. The content of the polymeric component in the coatings was 0 wt%, 38 wt% and 54 wt%, respectively. Ethanol was used as a solvent, whereas water was added for the hydrolysis reaction. Prior to the coating procedure, the coating sol was stirred for several hours in order to proceed with the hydrolysis to an adequate point. The coating application to the specimens was carried out by spill-coating followed by heat-treatment at 100 ºC to form thin, solid coatings through condensation reactions. The wood specimens were stored at 65% relative humidity (25 ºC) prior to assessing coating properties.Coating abrasion testing was performed by means of an Erichsen's washing apparatus described in DIN 53778 standard (Figure 1). The standard method was slightly modified in terms of the abrasive media: a Scotch-Brite pad was attached to the sledge sliding back and forth on the sample surface. The load applied on the samples surfaces was approximately 700 Pa. After every 100 abrasion cycles (back and forth moves), the surface quality of the coatings was determined by contact angle and gloss measurements. The coatings were subjected to a total of 700 back and forth abrasion cycles.

Contact angle measurements with distilled water were carried out to detect the effect of sol-gel coatings on the repellent properties of wood and to indicate changes taking places on the coatings surfaces during the abrasion procedure. Additional liquids used for the surface energy determinations were as follows: analytical grades of ethylene glycol, formamide and methylene iodide. Contact angles were measured crosswise to the axes of the wood grains. The contact angles were recorded with a CAM 200 Optical Contact Angle Meter (KSV Instruments Ltd). Surface energy calculations were carried out by means of the SFE-CAM 200 software. The change in the specular-gloss of the coated surfaces as a result of abrasion was assessed with Micro-Tri-Gloss meter. In addition, topography changes due to abrasion were monitored with a scanning electron microscope (SEM). In the SEM analyses, both the secondary electron (SE) and the back scatter electron (BSE) imaging modes were used.

The effect of the coatings on water vapour permeability of wood was assessed by means of the standardized test method (EN ISO 12572). Results recorded after two weeks from the starting point of the test are reported here.

Results and Discussion

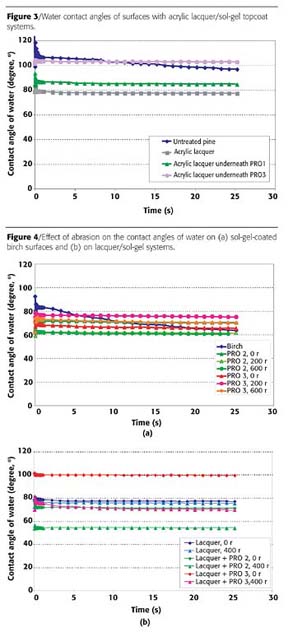

After the coating processes, visual observation showed that adhesion of the three sol-gel coatings to the wood and lacquer surfaces was good. In addition, the planed wood surfaces remained rather smooth; in other words, the extent of wood fibres sticking up through the surfaces as a result of the surface treatment with the aqueous sol-gels can be considered negligible.The effect of the sol-gel coatings on the repellent properties of wooden substrates was assessed by measuring static contact angles of distilled water on the surfaces as a function of time. The contact angles of water showed that the PRO 3 coating clearly improved the water-repelling properties of birch (Figure 2a). The two other coatings seemed not to have such a significant effect. Monitoring of the volume of the water droplets during the contact angle measurements revealed that the droplet volume on the PRO 3 surfaces decreased comparably with the one on non-permeable polypropylene surfaces (Figure 2b). This indicates that on PRO 3 surfaces, evaporation of water droplets rather than penetration into the substrate takes place during the monitoring time. PRO 1 and 2 coatings seemed to slightly slow down penetration of water into the substrate.

Despite the poor water repellence and water barrier efficacy of the PRO 1 and 2 coatings, the water vapour resistance factor of the specimens coated with PRO 1 and 2 was significantly higher than that of the reference samples (Table 1). Results of the specimens coated with PRO 3 were not available at this point.

Durability and performance of sol-gel coatings under different stress and environmental conditions needs to be known in order to evaluate the overall feasibility of the sol-gel-coated products. In this study, attention was focused on the abrasion resistance of the systems described above. The performance of the coatings in the Scotch-Brite abrasion test was evaluated by comparing the water-repellent properties, gloss and surface energies of the coating systems prior to and after the abrasion. No spreading of water droplets was observed on birch surfaces coated with PRO 2 and 3, even though the coatings were subjected to 600 or 700 abrasion cycles (Figure 4a). When the thin coatings PRO 2 and 3 were used as a topcoat for lacquered wood surfaces, a significant drop in the water contact angles on the abraded PRO 2 surfaces was recorded. However, the contact angles of the abraded PRO 2 surfaces were much lower than those of the abraded lacquer surfaces (Figure 4b). A potential explanation for the result could be the following: the polymeric component of the PRO 2 coating is worn off, but the lacquer surface underneath is not yet exposed. Contrary to the PRO 2 coating, PRO 3 is more sensitive to the abrasion and the lacquer layer underneath it was exposed at a rather early stage of the abrasion test.

SEM analyses of the PRO 2 coating also showed that even though clear defects and grooves were created in the abrasion, the PRO 2-coated surfaces are still partially covered by the coating (Figure 6). This is seen from the BSE-images in which the areas strongly covered by the coating appear in light grey, and the areas containing no or only a small amount of the coating appear in darker colour.

Conclusions

The results of the study are encouraging to consider sol-gel coatings as feasible surface treatments for wood e.g., as such or as a part of a surface treatment system. Improved water repellence and water vapour barrier properties can be achieved with sol-gel coatings. In addition, sol-gel coatings were proved to be fairly abrasion resistant even in such a harsh multi-scratch test as used in this study.This paper was presented at the Nano and Hybrid Coatings conference sponsored by The Paint Research Association, January 2005, Manchester, UK. Conference proceedings can be obtained by contacting Janet Saraty, Conference Administrator, at j.saraty@pra.org.uk.

Acknowledgements

The research was carried out within the project funded by National Technology Agency of Finland (Tekes), VTT and industry. The authors wish to thank also Tom E. Gustafsson (VTT) for performing the SEM analyses.

References

1 Lee, M.S.; Jo, N.J. Sol-Gel Sci. Technol. 2002, 8,443-449.

2 Tshabalala, M.A.; Gangstad, J.E. J. Ctgs. Technol. 2003, 75(943), 37-43.

3 Tshabalala, M.A.; Kingshott, P.; VanLandingham, M.A.; Plackett, D. J. Appl. Polym. Sci. 2003, 88, 2828-2841.

4 Mai, C.; Militz, H. Cost E22 Action, 2003, Tuusula, Finland.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!