Silicone Surfactant Additives

December 5, 2024Silicone Surfactant Additives

December 5, 2024courtesy of: Kesu01 / Creatas Video+ via Getty Images Plus

Silicone surface additives are essential in many industrial applications, such as the formulation of paints, inks and coatings. Their main advantage relies in their ability to reduce surface tension, improving wetting on various substrates. Additionally, they offer specific functionalities that enhance product performance.

What do Silicone Surfactants Mean as a Chemical Product?

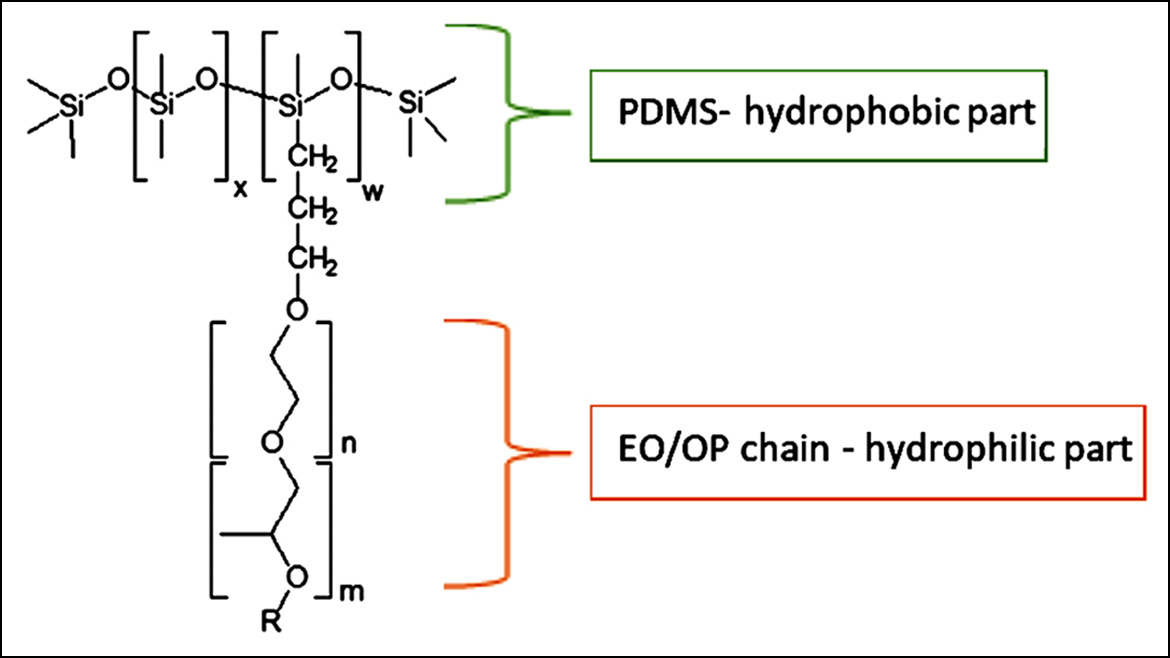

Silicone surface additives are amphiphilic compounds where permethylated siloxane hydrophobic chain (polydimethylsiloxane, PDMS) is coupled to one or different polar groups. The most common polar groups are nonionic ethylene oxide (EO) and propylene oxide (PO) units, though other types exist. The number of x and w units regulates the molecular weight of the polydimethylsiloxane chain, and the ratio between them determines the degree of branching. The PDMS and polyether groups are joined by a stable propyl linker (-CH2CH2CH2-), which is nonhydrolyzable, providing durability in various applications.

The ratio between the number of ethylene oxide (EO, n) and propylene oxide (PO, m) units determines the polarity of the polyether, while their sum defines its molecular weight. The polarity of this part affects the interaction with the different systems. Another crucial factor is the terminal group of the polyether chain, which can either be a hydroxyl (-OH) group or substituted with other nonreactive functional groups. This is especially important in formulations containing reactive chemicals, such as isocyanates, where wetting agents with non-reactive terminal groups are preferred.

When a coating containing silicone additive is applied to the surface, the nonpolar PDMS segment aligns toward the air, while the polar part interacts with the liquid phase, giving these copolymers their surfactant properties. By reducing the surface tension of liquids, they lower the contact angle between the coating and the substrate, thereby improving surface wetting.

Applications and Benefits

Silicone wetting agents are crucial in formulations designed for surface treatments, such as paints, coatings, varnishes and printing inks. These additives are nontoxic, highly effective in low concentrations, and compatible with a wide range of water-based and solvent-based systems.

Low-molecular-weight silicone additives are particularly effective in preventing common surface defects, such as craters and fisheyes. They also enhance leveling and significantly reduce surface tension, making them ideal for water-based formulations or difficult-to-wet surfaces. These additives are commonly used in systems that require multiple layers of coatings.

Medium- and high-molecular-weight additives are equally important in preventing surface defects, such as craters due to their moderate reduction of surface tension. This ensures proper adhesion and defect-free coverage. They can also address other surface issues, such as the orange peel effect, which arises from solvent evaporation or the curing process of the coating, leading to surface tension imbalances.

Surface Tension

Surface tension refers to the energy required to increase a liquid’s surface area, which is a result of intermolecular forces between surface molecules. Liquids with strong intermolecular forces exhibit high surface tension.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

Various methods are used to measure surface tension, one of the most common being the Du Noüy ring, which assesses the liquid’s static surface tension. However, in the dynamic industrial processes like roller coating or printing, measuring dynamic surface tension is more relevant. This can be achieved using the Bubble pressure method, where bubbles are generated at different frequencies in a liquid, and the pressure needed to form the bubbles is directly related to the liquid’s surface tension.

For pure liquids, surface tension remains constant regardless of bubble lifetime. However, in the presence of surfactants, surface tension depends on how quickly the surfactants can migrate to newly formed surfaces, meaning the dynamic surface tension varies with bubble lifetime. At Concentrol, our R&D labs are equipped with advanced bubble pressure tensiometers, capable of measuring dynamic surface tension across a wide range of bubble lifetimes, from 15 milliseconds to 100 seconds. This allows us to observe the behavior or different wetting agents, predicting their performance in various coating systems and supporting the development of innovative additives.

Regulatory Considerations—SVHC-Free Additives

Since June 2018 (ED/61/2018), silicone additives containing more than 0.1% of cyclic silicones D4, D5 or D6 must be declared as Substances of Very High Concern (SVHC) in the European Safety Data Sheets. Silicone surface additives with significantly reduced levels of cyclic silicones are available, thanks to an additional purification step during production. This process ensures that the additives contain less than 0.1% of D4, D5 and D6, meaning no SVHC labeling is required for this product range.

Furthermore, most of our silicone additives comply with FDA food contact regulations, and many meet the requirements of BfR Chapter XV and EU Regulation No. 10/2011.

Research and Development in Silicone Surface Additives

A new range of silicone surface additives (ORDISOL) provides optimal solutions for formulators seeking to enhance surface properties in their products. These additives are organofunctional silicones composed of nonhydrolyzable polysiloxane-polyether copolymers, ensuring excellent stability under extreme conditions such as high temperatures or corrosive environments. This product line is divided into two main categories: Substrate Wetting and Anti-Crater Additives; and Surface Control Additives

Substrate Wetting and Anti-Crater Additives

These additives are designed specifically for printing inks and water-based systems, where surface tension needs to be drastically reduced. In these coatings, water’s high surface tension makes wetting difficult. Additives in this range can reduce water’s surface tension to nearly 20 mN/m, significantly improving leveling and reducing craters or contaminated surfaces.

Surface-Control Additives

These additives are suitable for solvent-based, solvent-free and water-based systems. They enhance leveling and flow while reducing craters. Additionally, they modify the surface properties of the coating, improving mechanical characteristics such as scratch resistance and abrasion protection.

For more information, visit www.concentrol.com.