Paving the Way for Digital Innovation in the Paint and Coatings Industry

Building the Data Foundation

In the competitive coatings industry, enhancing efficiency and accelerating the speed of innovation are key objectives. The digital paint formulation approach supports these goals by serving as a powerful tool for researchers.

It augments traditional methods with advanced digital capabilities, using machine learning and advanced algorithmic models to effectively predict the properties of new formulations. This approach enhances a paint and coatings manufacturer's ability to innovate swiftly and effectively, ensuring a leading position at the forefront of industry innovation and competitiveness.

Despite its immense potential, constructing a digital formulation tool can often be a daunting and time-consuming task due to the absence of efficient data infrastructure. Recent studies reveal that data practitioners devote 80% of their time to locating, cleansing, and organizing data, while only 20% is spent on actual data analysis or model building.1

In the context of digital transformation within the coatings industry, creating a robust data foundation is of paramount importance. This foundation extends beyond mere data accumulation; it involves building a reliable infrastructure that underpins the entire digital ecosystem.

Data Management: The Keystone of Transformation

Data management is the foundation of this transformation, encompassing the meticulous collection, storage, and utilization of data to ensure its integrity and value. The process commences with the gathering of high-quality data, which is subsequently enriched with detailed metadata to provide context and facilitate their use. These data are preserved within a robust architecture that guarantees their accessibility and usability for future applications. A solid data structure is essential not only for the sustainability of the tool, but also for its enduring relevance.

For researchers to transition from manual coatings formulation to digital formulation successfully, this process must be underpinned by carefully curated and robust data. This foundational data is indispensable for powering advanced analytics, artificial intelligence, and other digital technologies that drive innovation and efficiency in the industry.

Researchers can actualize this concept by developing an integrated data management solution that spans the entire data life cycle from the ground up. By eliminating manual data manipulation and hand off, all relevant data are collected and stored. This can be achieved by designing custom devices that link lab equipment with computers, developing custom programs for automated data transfer and storage, and establishing a system that allows data retrieval based on a researcher’s requirements.

For effective adoption, these solutions must be holistic in scope to minimize the number of tools researchers have to interact with, and broadly accessible to be used in lab environments. With a robust data management system in place, digital formulating tools that enhance user experience and productivity can be launched more efficiently (Figure 1).

Enhancing Data Quantity and Quality Through High-Throughput Research and Automation

High-throughput research (HTR) is a transformative tool that rapidly and consistently generates data via automation. In paint formulation development, HTR allows researchers to quickly screen numerous paint formulations and simultaneously test performance, providing more reliable and quantitative data. This increased efficiency not only accelerates innovation, but also produces a high-quality dataset that refines models and advances the coatings industry.

For example, Figure 2 shows a high-throughput method developed for a block resistance test.2 Unlike the subjective bench test method, a texture analyzer delivers more quantitative results by gauging pull-off forces. This increases statistical accuracy and reduces operator variability, while increasing throughput.

Although high-throughput research offers game-changing benefits, not all companies in the coatings industry may have the resources to invest in such advanced technologies. Companies can still benefit from HTR by strategically investing in automation capabilities for efficiency gains.

As Figure 3 shows, an ideal initial HTR investment involves assessing test methods based on automation level and speed. Those in the first quadrant, offering the highest automation level and speed improvements, are best suited for HTR.

Even with smaller-scale automation, companies can streamline processes, improve data management, and speed up innovation. Collected data are transferred and stored using the previously mentioned data management system, employing custom devices and programs for automatic data transfer. This automation is vital in industries like coatings, where the ability to quickly create and analyze large datasets significantly reduces time from research to market.

Seeing Beyond: The Role of Computer Vision in Coatings Performance Evaluation

In an industry where visual appeal is critical, many application tests in the coatings sector involve subjective sample evaluations. This can result in inconsistencies and errors, largely dependent on the researcher's experience level. To mitigate this, computer vision is instrumental to digital transformation.

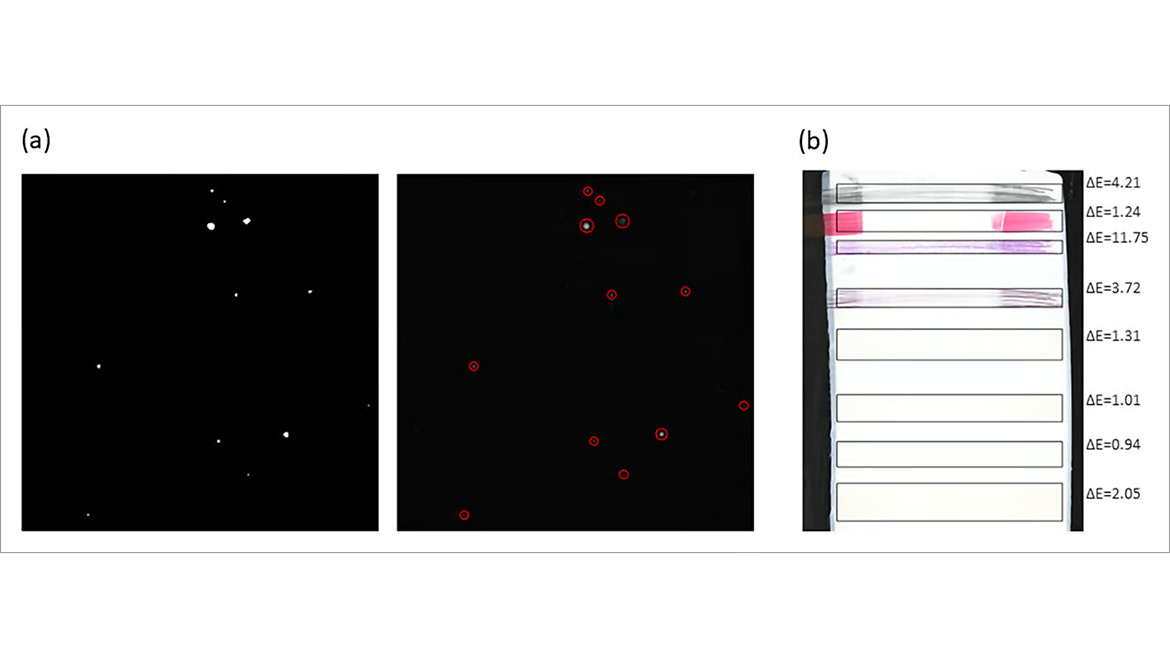

Computer vision diminishes the subjectivity and data inconsistency of visual assessments by focusing on two key areas of standardization: the development of standardized imaging equipment for uniform image acquisition, and the utilization of algorithms to analyze and quantify defects and produce test panel ratings.

Algorithms are developed based on test methods categorized by color, texture, defect identification, and area quantification. They are designed to pinpoint regions of interest, evaluate coating properties, and provide a quantitative metric.

Figure 4 showcases examples of computer vision algorithms developed for architectural coatings applications. These algorithms can automatically identify regions of interest and provide quantitative metrics. As a result, the data generated is more reliable and quantitative compared to subjective measurements, providing data-driven insights into coating performance.

Case Study: How Researchers Can Use Data Modelling to Improve Customer Value

When bringing new and innovative products to market, there is often a significant learning curve when it comes to formulation and getting the most out of the product. This requires extensive involvement from technical service to ensure the coatings manufacturer has a good experience and can successfully implement the product in new formulations. Typically, this begins with a recommended starting point formulation from the supplier for drop-in use in an existing formulation of interest. This is followed by months of back and forth to determine why the advertised benefits were not realized and how to formulate around the issue.

Using design of experiments, data infrastructure, and modeling, it is possible to efficiently explore the target formulation space and build property models, which help the supplier to provide better formulation guidance to consider the manufacturer’s particular formulation parameters and desired performance property balance. This approach gives the manufacturer a much better chance of success in their initial experiments, significantly lowering the time and effort required for implementation.

This approach was successfully demonstrated in Dow’s OPTI-MATT™ acrylic emulsion, a durable matte binder technology. To smooth customer implementation, over 950 paint samples were produced and characterized using HTR and digital benchtop methods. The resulting dataset was used to generate robust models for critical properties such as gloss, block, scrub, and stain.

The results were incorporated into a digital tool that allows the formulator to select the formulation parameters and raw materials they are interested in, as well as their preferred property balance to generate a customized starting point formulation. This tool was deployed to the DOW™ Paint Vision platform for direct customer use and used by technical service personnel in their work with their end customers.

Embracing Change in Digital Formulation

While the advantages of digital paint formulation are well documented, the transition from traditional methods can be met with hesitation. A strategic approach to change management is crucial for facilitating a smooth shift to digital practices.

- Leadership and Sponsorship: The success of digital tool adoption hinges on visible and proactive leadership support. Implementing best practices is essential, involving widespread team participation and clearly defined roles. It's important to empower researchers to establish their methodologies and priorities, ensuring they receive timely and constructive feedback.

- Communication Strategies: Effective communication is the cornerstone of change management. It's vital to articulate the benefits of digital formulation across all organizational levels, from team gatherings to managerial conversations. Utilizing diverse communication channels, such as user-friendly websites and dedicated Teams channels, can significantly enhance message dissemination.

- Building a Sustainable Digital Lab: Developing a digital laboratory is an ongoing journey, not a one-time event. It requires a robust strategy and continuous effort to create the necessary digital infrastructure and supporting datasets.

Conclusion

Data management is the foundation upon which digital transformation is built. The integration of high-throughput research, automation, and imaging standardization allows generation of high-quality and abundant data, which is crucial for the creation of advanced digital tools. These tools empower researchers to harness the power of data, driving innovation and maintaining a competitive edge in the coatings industry.

References

1 Press, G. Cleaning Big Data: Most Time-Consuming, Least Enjoyable Data Science Task, Survey Says. Forbes. April 14, 2022.

2 Henderson, K.; Agrawal, A.; Donovan, M.; Ell, J.; Tran, M,; Vuong, S. High Throughput Experimentation—A Faster Path to Innovation and Market Success. American Coatings Show, 2020.

3 Wang, S. Quantitative Image Analysis of Roller Application Performance. American Coatings Show, 2024.

4 Hu, Y.; Henderson, K.; DeRocher, J.; Kim, S. H.; Marianelli, A.; Liew, A.; Bisht, N.; Igram, M.; Tran, M.; Liu, Y.; Xi, C.; Linse, M.; Weeks, M. Advanced Digital Data Capture and Analysis Tools Replacing Traditional Visual Performance Ratings of Coatings. AIChE Spring Meeting & 19th Global Congress on Process Safety, 2023.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!