Enhanced Graffiti Protection

September 16, 2024

Enhanced Graffiti Protection

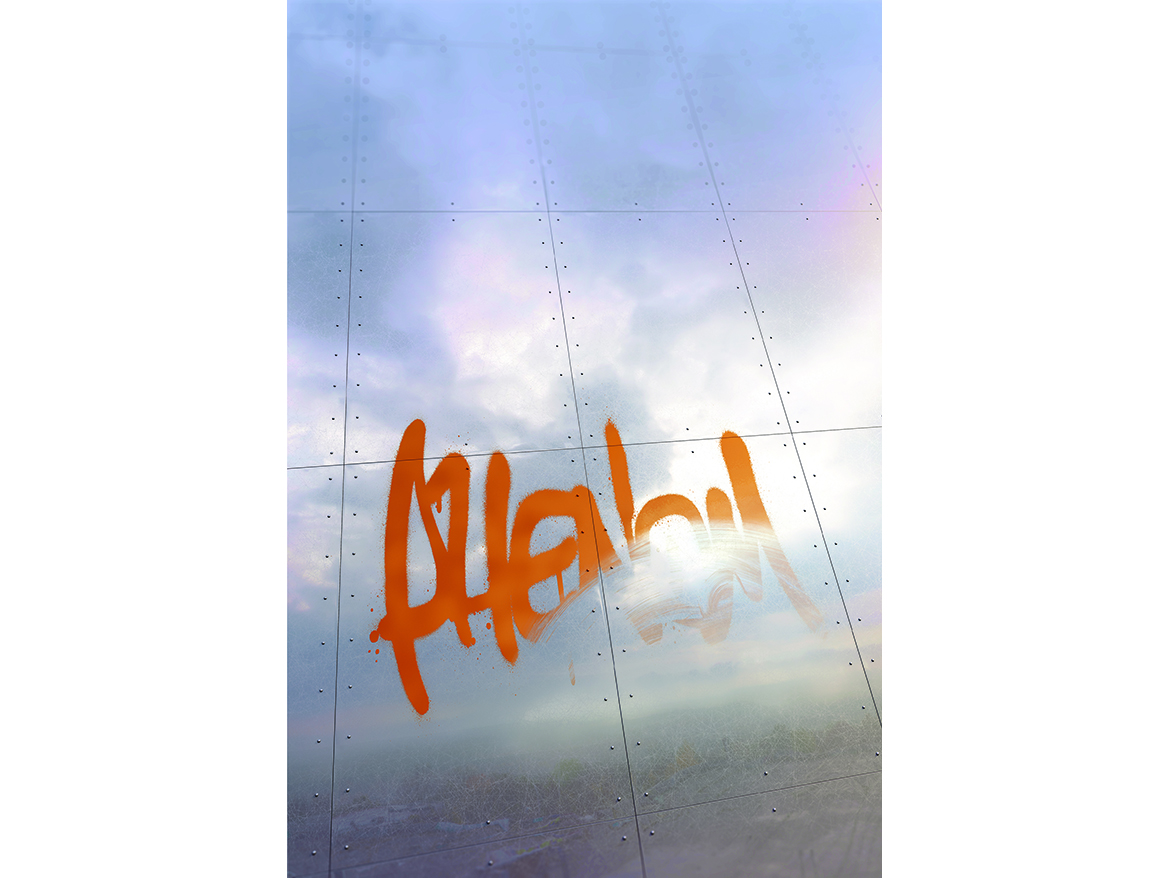

September 16, 2024Unwanted graffiti can plague municipalities, businesses, and communities everywhere. It can hamper commerce, lower property values, encourage blight, and drain public resources that could be better spent in more meaningful and impactful ways.

In fact, unwanted graffiti costs U.S. taxpayers an estimated $12 billion annually, but the real number may be much higher considering that it is an under-reported problem.

Utility poles are one of the most popular targets for graffiti because they are often located in highly visible areas and easily accessible. As one of the leading global manufacturers of poles used for telecommunications, energy, and lighting, Valmont Industries partnered with PPG to help tackle the problem.

Traditionally, manufacturers of utility poles like Valmont rely on an industry-standard, two-coat anti-graffiti system that limits production capacity and presents challenges (such as cleaning and touch ups) in the field after installation. The process consists of a polyester powder basecoat for color and corrosion protection, followed by a clear anti-graffiti powder topcoat. It is a cumbersome and time-consuming process, resulting in increased labor demands and costs for manufacturers, and their customers.

In essence, the market needed a new, more efficient solution. Finding a quicker way to tackle graffiti was vital since organizations that study graffiti have found that removing it within 24 to 48 hours has a profound impact on preventing reoccurrence. This is because graffiti tends to have a cumulative effect.

But rapid removal isn’t always so simple. It takes manpower and often harsh chemicals that require protection such as goggles and gloves. Sandblasting and re-painting may also be necessary depending on the scale of the graffiti.

Coatings companies like PPG are developing safer, more efficient solutions that are specially formulated to protect substrates from the effect of the graffiti paint itself, and the chemicals required to remove it.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

Traditional Graffiti Prevention Methods

The industry-standard two-coat anti-graffiti system for utility poles has a few drawbacks. Each batch requires pre-heating the substrate, applying the polyester powder basecoat, baking, and cooling. The process is then repeated for clear powder topcoat application, requiring about an hour in total for both coats.

The process is not only time consuming, but achieving a full and proper cure for both coats can be problematic, resulting in finishing defects that not only impact the aesthetics, but can leave parts vulnerable to corrosion. In one study conducted by Valmont, approximately 10% of poles using this process require re-work due to blistering and other defects such as spider veining in the clearcoat, a brittle basecoat from imprecise curing, and bubbling in the topcoat.

Next-Gen Collaboration

Valmont sought a new graffiti-resistant solution that would not only benefit their end-use customers, but also streamline their own production.

Through a partnership with PPG, Valmont began testing a new one-step PCU anti-graffiti powder, hoping that it would reduce both finishing time and the amount of re-work required.

The coating featured a urethane powder, tinted to a specific color and cured at 435 °F (224 °C), for 20 minutes. This is a 40-minute savings per batch versus the standard industry system. No additional steps were required because the single coat provided both color and graffiti-resistance properties. Further testing revealed that the need for re-work was virtually eliminated.

The tests also showed that graffiti could be removed with 90% isopropyl alcohol or Turtle Wax® Scratch & Swirl Remover with no loss in gloss and no need for protective gear, a groundbreaking development for linemen, municipal crews, and others charged with pole maintenance.

Cracking the Color-Matching Code

Utility and telecommunication poles feature a multitude of parts that are sourced from different manufacturers, made from assorted substrates such as steel, fiberglass, and plastic, and finished with a combination of powder and liquid coatings. These different chemistries and suppliers make color matching for field repairs a significant challenge.

Because PPG is a single-source supplier of coatings in every major chemistry with formulations engineered for a wide range of substrates, the company’s color matching process has proven to be easier and more accurate.

Through the partnership with PPG, Valmont is now able to send precision color-matched aerosol touch-up sprays with every pole order, something that had never been done before.

Not only does the anti-graffiti powder benefit Valmont’s end-use customers with less time needed for pole upkeep, but it transformed the company’s own finishing operations. Today, less time is needed for pole re-work, more parts are completed per shift for faster turnaround, and less space is required to store parts in various stages of processing.

The Future of Graffiti Protection

The development of advanced graffiti-resistant powder coatings is a major leap in maintaining the integrity and aesthetic appeal of public and commercial spaces. By making cleanup easier and more efficient, anti-graffiti coatings help to preserve property values, enhance community appearance, and allow municipalities to allocate public resources to more meaningful initiatives.