PFAS-Free Additives for Continuous Processes

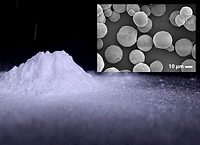

Specialty chemicals manufacturer BYK is providing its customers in the thermoplastics industry with two innovative PFAS-free product solutions that master many current challenges in the production of films, pipes, profiles, fibers and much more. BYK-MAX P 4109 and BYK-MAX P 4110 prevent melt fracture, reduce the viscosity of the melt, reduce die build-up, and allow faster material changes.

When processing polyolefins, high-shear forces, temperatures, and friction sometimes occur in the machines, leading to melt fracture or die build-up. In order to prevent these undesirable side effects and optimize production, fluorine-containing processing aids have often been used to ensure good throughput and defect-free finished parts. However, there are currently international legal initiatives to restrict the use of fluoropolymers (PFAS). BYK was quick to develop alternative additives that are PFAS-free and still have the usual positive effect on the process and result.

BYK-MAX P 4109 and BYK-MAX P 4110, two new polymer processing aids (PPA) from BYK, are PFAS-free and at the same time allow a high production speed, while preventing melt fracture and reducing die build-up, which leads to less maintenance and therefore shorter downtimes.

The rapid effectiveness of the two additives cuts long rinsing times and allows fast product changes. In addition, both products are thermostable and are easy to handle.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!