Polymeric Solutions for a Sustainable Future

A Case Study

At a major global blue-chip nickel mine in Australia, authorized Belzona distributor, Rezitech, provided a full turn-key solution to combat corrosion under insulation on an ammonium-sulphate feed tank. Within the space of 24 hours, the 9.5 meter (31.2 ft) diameter tank (with a height of 2 meters (6.6 ft) from ground level) was repaired and protected against future corrosion with the industrial composite wrap system, Belzona SuperWrap II.

Composite wrap system curbs corrosion under insulation at nickel mine.

Composite wrap system curbs corrosion under insulation at nickel mine.

Protective Coatings and Epoxy Repair Systems Support Transition to Net Zero

The mine refines granulated nickel matte from their smelter into premium-grade nickel powder and briquettes containing 99.8% nickel. Nickel powder is further processed into nickel sulphate at a refinery in Australia. Nickel sulphate is an essential ingredient in the lithium-ion batteries that drive electric vehicles (EVs).

It could be argued that the increase in sales of EVs is one of the biggest climate wins of 2023.

Indeed, according to the 2023 Report from Climate Action Tracker, of the 42 sectors that need to achieve net zero status by 2050, the only sector on track is the share of EVs in light-duty vehicle sales. Considering how road transport currently accounts for 11% of global greenhouse gas emissions, EVs play a vital role in reducing these emissions.

As such, the polymeric technology required to repair and improve assets within the EV industry equally plays a vital role in supporting the transition to net zero. By repairing damaged assets instead of decommissioning and sending them to landfill, this significantly reduces the climate impact that would otherwise be incurred in this process.

Case Study: Feed Tank Suffering from Corrosion under Insulation & SCC

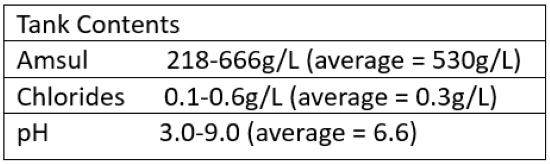

The customer’s stainless steel feed tank was suffering from corrosion under insulation and chloride-induced stress corrosion cracking. They required a solution that would not only restore the integrity on the substrate, but also protect the asset against future corrosion damage. Not only this, but as the tank operates at elevated temperatures of approximately 70 °C (158 °F) and processes highly corrosive medium, the repair solution would need to be able to withstand these harsh conditions.

TABLE 1 | Tank contents.

Composite Wrap Solution

Having worked with Rezitech over the course of five years, the customer had complete confidence in the range of Belzona metal epoxy repair composites and industrial repair coatings the distributorship offers. As such, they decided to contact them again for their advice and system recommendation.

Following an inspection by Heath Westell, Sales Engineer at Rezitech, the composite wrap system was specified.

Commenting on this specification, Heath said, “This composite wrap system is comprised of a fluid-grade resin system, a bespoke hybrid reinforcement sheet, based on fiber glass and carbon fiber, as well as a release film to compact and consolidate the application. The system is specially formulated to restore the strength of holed, weakened and corroded pipe and tank walls, making it the ideal solution for protecting the asset against corrosion under insulation for the long term. In addition, thanks to the cold-curing properties of the composite wrap system, this mitigates the need for hot work, making it a reliable alternative to welding.”

Application Procedure

Firstly, all traces of oil and grease contamination were removed using a suitable Rezitech degreaser. Following this, the surfaces were grit-blasted to provide a surface cleanliness compliant with ISO 8501-1 SA 2½ (ASNZ 1627.4 class 2.5) with a minimum 75 µm (3 mil) rough angular profile.

Once the surface was prepared, the Belzona 9381 reinforcement sheet was measured out and then wetted out with the Belzona resin system. The resin was then systematically applied to the areas to be repaired. Following this, reinforcement sheets were then applied to the tank in three layers. The compression film was then added to the top of the application area. Next, using a roller, the composite wrap system was then spread, rolled, and compressed to the surface of the tank. The system was then left to cure for approximately eight hours.

Stainless steel feed tank repaired and protected with the composite wrap solution.

Stainless steel feed tank repaired and protected with the composite wrap solution. Bypass the Need for Replacement with Polymeric Technology

By investing in the composite wrap solution, this enabled the customer to successfully bypass the need to replace the corroded asset, and instead prolong the lifespan of the asset for years to come. Thus, this enabled the customer to make significant savings in both time and money. In addition, given the important role EVs play in reducing global carbon emissions, it could be argued that polymeric technology also plays a fundamental role in supporting this transition by safeguarding the integrity of key assets within this industry.

Mitigate the need for replacement with polymeric technology.

Mitigate the need for replacement with polymeric technology.

For more information, visit: www.rezitech.com.au/products/belzona.

*Images courtesy of Belzona.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!