Enhancing Sustainability with Pigging Technology

Image credit: imantsu. iStock, via Getty Images.

The paint and coatings industry plays a significant role in various sectors, including construction, automotive, and consumer goods. However, the manufacturing processes in this industry often result in significant waste generation and environmental impact.

To address these challenges and enhance sustainability, companies are increasingly turning to innovative technologies such as HPS’ advanced liquid product recovery (pigging) technology.

This article will explore how pigging technology is revolutionizing the paint and coatings industry by minimizing waste, reducing resource consumption, and improving overall efficiency.

Understanding Advanced Liquid Product Recovery (Pigging) Technology

Advanced liquid product recovery (pigging) is an innovative technology designed to recover residual liquids from pipelines during product changeovers.

This fully automated technology utilizes a specially designed projectile, known as a pig, which travels through the pipeline, pushing the remaining product to its destination. By effectively recovering residual product, pigging technology helps companies minimize waste, optimize product usage, and reduce the need for cleaning agents.

Pigging technology is used in a wide variety of sectors, but is especially popular in the paint and coatings industry due to being a practical solution to many of the challenges faced by manufacturers. Pigging solutions help manufacturers adhere to strict regulations regarding volatile organic compounds (VOCs), minimize contamination risks, and effectively recover product.

Benefits of Pigging Technology

In the paint and coatings industry, operational processes often result in significant waste generation and environmental impact. During product changeovers, residual paints and coatings are traditionally flushed out of pipelines, leading to substantial waste volumes and associated disposal costs.

Pigging technology, however, offers a transformative solution to these challenges. Here's how:

- Waste reduction: In the paint and coatings industry, product changeovers often result in significant waste generation as residual paints and coatings are flushed out of the pipelines. High-performance pigging technology enables companies to recover up to 99.5% of residual product from full pipelines, significantly reducing waste volumes and associated disposal costs.

- Resource optimization: By recovering residual product, pigging technology allows manufacturers to optimize their resource usage. Rather than wasting valuable materials during changeovers, companies can effectively utilize their products, thereby reducing raw material consumption and lowering production costs.

- Environmental impact: Traditional cleaning methods in the paint and coatings industry often involve the use of harsh chemicals and large volumes of water, leading to environmental pollution and resource depletion. Pigging technology offers a sustainable alternative by optimizing the use of cleaning agents and water, thus reducing the industry's carbon footprint and preserving natural resources.

- Energy efficiency: The efficient recovery of residual product with pigging technology also contributes to energy savings. By reducing the need for extensive cleaning processes and minimizing downtime associated with product changeovers, companies can optimize their energy consumption and improve overall operational efficiency.

Pigging technology is an innovative solution in the paint and coatings industry, addressing key challenges, while advancing sustainability goals. Through waste reduction, resource optimization, and minimized environmental impact, pigging offers a multi-faceted approach to enhancing operational efficiency.

By recovering up to 99.5% of residual product, companies significantly reduce waste volumes and associated disposal costs. Additionally, the optimization of resource usage and the reduction of environmental footprint through sustainable alternatives underscore the transformative impact of pigging technology.

Case Studies: Implementing Pigging Technology for Sustainability

Barbot Paints, a leading Portuguese paint manufacturer, implemented custom-designed pigging technology into its transfer lines to reduce bacterial contamination. The company was also able to implement water recycling into its processes because of pigging technology.

By recovering residual paints from pipelines, rather than allowing it to stand in the line, Barbot has reduced its product recalls by over 99%. This has equated to less wasted product, improved sales, and substantial cost savings.

Additionally, the use of pigging technology is helping Barbot Paints minimize its environmental footprint and improve its corporate social responsibility initiatives.

Carbon Reduction with Pigging Technology

An undisclosed paint company, for reasons of confidentiality, integrated pigging technology within its manufacturing operations and participated in a comprehensive carbon study. This study showed a remarkable reduction in carbon emissions per changeover.

The study examined the carbon emissions associated with both water- and solvent-based paint changeovers. Using traditional changeover procedures, water-based paint produced 2.7 tonnes of CO2e, and solvent-based paint produced 2.6 tonnes of CO2e. The study accounted for pump energy use, wastage, water supply, water treatment, solvent flushes, solvent collection, and solvent recovery.

Accounting for the same factors plus the embodied carbon within an HPS pig, the carbon emissions for water-based paint changeovers dropped by 99.3% to 0.02 tonnes of CO2e. The carbon emissions for solvent-based paint changeovers dropped by 90.8% to 0.24 tonnes of CO2e.

Using this data, it can be assumed that for every 250,000 changeovers performed with a pigging system, at least 670,000 tonnes of CO2e are prevented from entering the atmosphere. That’s equivalent to taking 145,600 fuel-powered cars off the road.

Businesses that use pigging technology as part of their environmental and corporate social responsibility strategies are actively contributing to reducing carbon emissions. By focusing on eliminating carbon creation, rather than carbon capture or carbon offsetting, businesses help the environment and enable the manufacturing sector to move towards a lower carbon footprint.

Specialist Pigging Configurations

Paint and coatings manufacturing processes can be complex, requiring specialist pigging system configurations for optimum efficiency and performance.

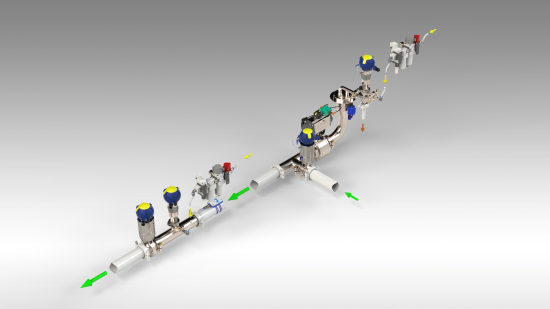

Among the various configurations available, one key pigging system stands out: The dual-pig pigging system is a configuration specifically designed for use in the paint and coatings industry. The dual-pig pigging system enables manufacturers to recover product and perform an initial clean simultaneously, cutting changeover times and optimizing resource use.

The dual-pig pigging system uses two separate pipeline pigs that are released into the pipeline with a measured “slug” of solvent or water between the two pigs. The leading pig pushes the residual product to its destination whilst the slug of fluid between the pigs acts as a flush.

One challenge that manufacturers across sectors struggle with is knowing how much water and/or cleaning fluid they need to effectively clean their lines. Using the dual-pig pigging system, manufacturers can improve their environmental friendliness by cutting water and chemical consumption. These benefits are in addition to reducing wastage through recovery and cutting carbon emissions per changeover.

More Benefits of Pigging for Paint and Coatings Manufacturers

Improved sustainability isn’t the only benefit of pigging technology for manufacturers. There are also practical and financial benefits that derive from implementing a sustainable technology.

The primary purpose of pigging technology is product recovery. By recovering product and increasing yields, manufacturers improve profits, reduce waste and effluent disposal related costs, and make full use of raw materials.

Increasing yields improves the financial sustainability of a company, and, although the initial investment may seem high, a good quality pigging system will typically pay for itself within 6-12 months. After this initial payback period, any product recovered contributes solely to profitability.

Pigging technology is also efficient, with the recovery sequence almost always contributing to decreased downtime and faster changeovers. Many manufacturers who use quality pigging systems experience a decreased downtime of over 80%, enabling them to increase their capacity and product output. These manufacturers also save on non-productive labor costs.

Finally, by using the optimal amount of chemicals in clean-in-place (CIP) procedures, manufacturers also save on costs associated with purchasing said chemicals. Many of these chemicals aren’t environmentally or financially friendly. Using the exact amount of chemicals required to maintain or improve product quality decreases company overheads and allows for greater investment in sustainable technologies.

The Future of Paint and Coatings Manufacturing

The outlook for the paint and coatings industry is promising as environmental considerations take center stage in business strategies. With growing awareness of the need for sustainable practices, the adoption of innovative technologies like pigging technology is expected to surge.

Pigging technology’s capability to recover up to 99.5% of residual product from full pipelines underscores its potential to transform liquid processing. Pigging offers manufacturers the opportunity to optimize resource usage, and minimize their environmental footprint through sustainable, long-lasting technology, signalling a shift in industry practices.

The ability of pigging technology to minimize waste, optimize resource usage, and reduce environmental impact positions itself as a key solution for manufacturers striving to enhance their sustainability credentials while maintaining operational excellence.

Through case studies and carbon reduction analysis, the tangible benefits of pigging technology in enhancing operational efficiency and sustainability become evident. The utilization of specialist pigging configurations, such as the dual-pig pigging system, further enhances these advantages, enabling manufacturers to streamline processes and reduce environmental impact.

As companies increasingly prioritize sustainability goals to meet consumer demands and regulatory requirements, investments in advanced technologies such as pigging technology will be instrumental. By embracing these solutions, manufacturers not only reduce their environmental footprint but also improve cost efficiency and competitiveness in the market.

For more information, click here.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!