New Insights into Coating Additives to Improve Durability of Waterborne Coatings

Arand, Creatas Video, via Getty Images.

Product lifecycle analysis shows that high-performance coatings with improved durability prevent inefficient use of material resources and energy from start to finish. Abrasion is one of the most important defects that deteriorates the durability of coatings. Abrasion is defined as the process of marring, scratching, or wearing away any part of a material by rubbing it against another surface.1 Although the terms abrasion, mar, scratch, and wear are sometimes used interchangeably in industry, they are different. Mar abrasion is the permanent deformation that has not ruptured the surface of a coating. However, wear abrasion is usually caused by mechanical actions that remove material from the surface. In most cases, such removal is gradual and progressive due to repetitive actions. In addition to abrasive wear, several other types of wear include adhesive, corrosive, cutting, deformation, fatigue, impact, and rolling. Scratch abrasion, typically seen as a line, is a surface deformation caused by indentation due to the displacement or removal of material by a harder object.2, 3 Abrasion resistance is the resistance of a solid material to mar, wear, and scratch.

In the coatings industry, different approaches can be used to achieve the required abrasion resistance. Among them, surface treatment and matrix strengthening are the widely utilized approaches. In some cases, a combination of these complex approaches performs the desired level of abrasion resistance. In organic coatings, using specific additives based on modified polydimethylsiloxane (PDMS), as well as natural or synthetic wax products, can sometimes improve abrasion resistance.4 Although their working mechanism is not very well understood yet, it seems these additives can migrate to the surface and act as slip agents or physical spacers. In addition to surface treatment, matrix strengthening is an effective approach for improving the abrasion resistance of organic coatings. This approach usually uses polymers with high glass transition temperature (Tg) values. In self-crosslinked one-component (1K) or crosslinked two-component (2K) coatings, it is possible to improve matrix strength by increasing the crosslinking density of the systems. Another efficient strategy is introducing hard particles into the matrix of organic coatings.5 Although matrix strengthening is a common approach, increasing the elasticity of a coating can sometimes improve its abrasion resistance by recovering after the applied stress is removed. In general, the introduction of reinforcements can affect mechanical properties such as hardness, stiffness, elasticity, and plasticity.6-14 A summary of different approaches for improving the abrasion resistance of organic coatings is schematically illustrated in Figure 1.

Accelerated abrasion testing is a necessity for coating manufacturers to produce quality products that remain free from defects throughout their life cycles. In industry, there are numerous instruments available that can simulate a wide range of abrasion modes. In general, they can work based on rotating disks or linear motions. In the coatings industry, abraser, shear tester, and Martindale are a few examples of accelerated abrasion testing instruments that work using rotating disks.15, 16 On the other hand, scrub-abrasion tester, heavy-duty linear abraser, crockmeter, and multifinger scratch tester are some abrasion-testing instruments that work based on linear motions.

Waterborne (WB) coatings for different applications have been available for several decades. The most important driver for switching from solventborne (SB) to WB coatings is stricter regulations related to reducing emissions of volatile organic compounds (VOCs). Regardless of significant advances in WB technologies, there is a significant need to improve their performance in the areas where high mechanical, chemical, and weather resistance are required. To better understand the abrasion resistance of WB coatings, this study focuses on the evaluation of variant approaches using different additives including structure-modified fumed silica, precipitated spherical silica, functionalized colloidal silica, slip additives, and co-binders. WB systems studied are based on 1K-acrylic emulsion and 2K-polyurethane dispersion (PUD). Different accelerated testing methods are used to investigate the effects of these factors on the final abrasion resistance properties of these systems.

Experimental

Materials

The general formula of the WB Coatings A and B investigated in this study are shown in Table 1. The acrylic emulsion used in Coating A is a modified-acrylic-copolymer emulsion with a minimum film-forming temperature (MFT) of less than 0 °C. The cosolvent used in these WB coatings is butyl glycol. The rheology additive used in the studied coatings is a hydrophobically modified ethylene-oxide-urethane (HEUR) associative thickener. A hexamethylene-diisocyanate (HDI)-based hardener is used in Coating B. All the additives used in these WB coatings are provided by Evonik Industries (Essen, Germany). The polysiloxane-based slip-surface additives used are SSA-1, SSA-2, SSA-3, and SSA-4. The nanosilica dispersion used is NSD, which is based on 43 wt.% of 20 nm nanosilica particles dispersed in water. HFS is used as a hydrophobic, easy-to-disperse, structure-modified fumed silica. The spherical precipitated silica used in this study is SPS. Moreover, cobinder additives CBA-1 (Tg ~30 °C) and CBA-2 (Tg ~120 °C) are used. In these WB coatings, the addition levels of structure-modified fumed silica, precipitated spherical silica, functionalized colloidal silica, and cobinders are 3.0, 5.0, and 10.0 solid wt.% calculated on the total solid contents of the formulations. The polysiloxane-based slip additives are added at 0.1 and 0.5 solid wt.% calculated on the total solid contents of the formulations. The list of additives used is shown in Table 2.

Characterizations

Different accelerated abrasion testing instruments such as abraser (Taber Industries), shear tester (Taber Industries), crockmeter (SDL Atlas), Martens hardness (Fischer GmbH), and Martindale (James Heal) are used to evaluate the abrasion resistance of the prepared coatings.

Abraser (Taber Industries) is a widely used instrument in the coatings industry. A method for its use is given in ASTM D4060. There are several procedures used to interpret the generated results using this instrument. The most common method is evaluating the number of cycles needed to reach a predetermined endpoint. The criteria evaluated may include loss in the coating, change in gloss, or other changes in appearance.17 In this study, the Taber abraser test is used with side weights of 500 g each, and wheels made of CS-10 sandpaper. The weight losses of coated panels are measured after 500 cycles. Shear tester (Taber Industries) is another method used to evaluate the abrasion resistance in this study. A specimen rotates at 5.0 revolutions per minute (RPM), and the scratching/marring occurs as the specimen comes in contact with either the diamond or carbide tools. An adjustable load is applied to the scratch tool. In general, mar resistance is reported as the amount of weight required to just produce a barely visible scuffing or loss of gloss.18 In this study, a diamond conical needle is used, and the weight needed to damage the coating is recorded. To evaluate the abrasion resistance using abraser and shear tester, the prepared WB coatings containing additives are applied on substrates by a 200 µm wire bar. After 30 min flash-off at room temperature, the applied coatings are cured for 2 h at 60 °C, followed by curing for 7 days at room temperature.

The abrasion durability is also tested by a crockmeter (SDL Atlas) equipped with a cloth pad. In this method, the pad is loaded with a constant 9 N charge and is moved back and forth with a sliding velocity of ~20 mm/s in a straight line.19 The gloss 20° values of the marred surfaces are measured using a micro-TRI-gloss (BYK Instruments). In addition, the abrasion resistance of the coatings on cotton fabric is evaluated by a Martindale (James Heal) instrument after 50 cycles, according to standard ASTM D4966.20 The gloss 20° values of the surfaces are measured and recorded before and after abrasion tests. Also, a Martens (Fischer GmbH) instrument is used to measure the hardness of the prepared coatings. This test is based on the principle of forcing the vertex of an indenter into the surface of a coating and measuring the indentation depth under a working force that has been maintained for 30 s.21 To measure the abrasion resistance using crockmeter, Martindale, and Martens instruments, the prepared coatings are applied on substrates by a 100 µm wire bar, followed by 30-min flash-off at room temperature. The applied coatings are then cured for 2 h at 60 °C, followed by curing for 7 days at room temperature.

Results and Discussion

WB Coatings A and B are used as the main systems to evaluate the effects of different additives on the abrasion-resistance properties. To make the formulations, polysiloxane-based additives SSA-1 and SSA-2 as well as PDMS emulsion-based additives SSA-3 and SSA-4 are used at 0.1 and 0.5 wt.% levels calculated on the total solid contents of the formulations. In addition, nanosilica dispersion-based additive NSD, hydrophobic structure-modified, fumed-silica-based additive HFS, spherical-precipitated silica-based additive SPS, polyester dispersion-based additive CBA-1, and polyurethane polyol-based additive CBA-2 are all used at 3.0, 5.0, and 10.0 wt.% levels calculated on the total solid contents of the formulations. To determine the effects of these additives on durability, with a focus on abrasion resistance, 23 formulations based on 1K-WB Coating System A and 23 formulations based on 2K-WB Coating System B are prepared. Within each of the two systems A and B, the additive type and addition level are varied.

In the Taber abraser test, the abrasion is produced by the contact of the sample with abrading wheels. When the sample rotates, the abrading wheels are driven in opposite directions. The resulting abrasion marks create a specific pattern in a circular band. This method involves localized and severe damage because of a high abrasive medium and contact stresses. Therefore, this technique leads to both superficial and subsuperficial abrasion mechanisms.

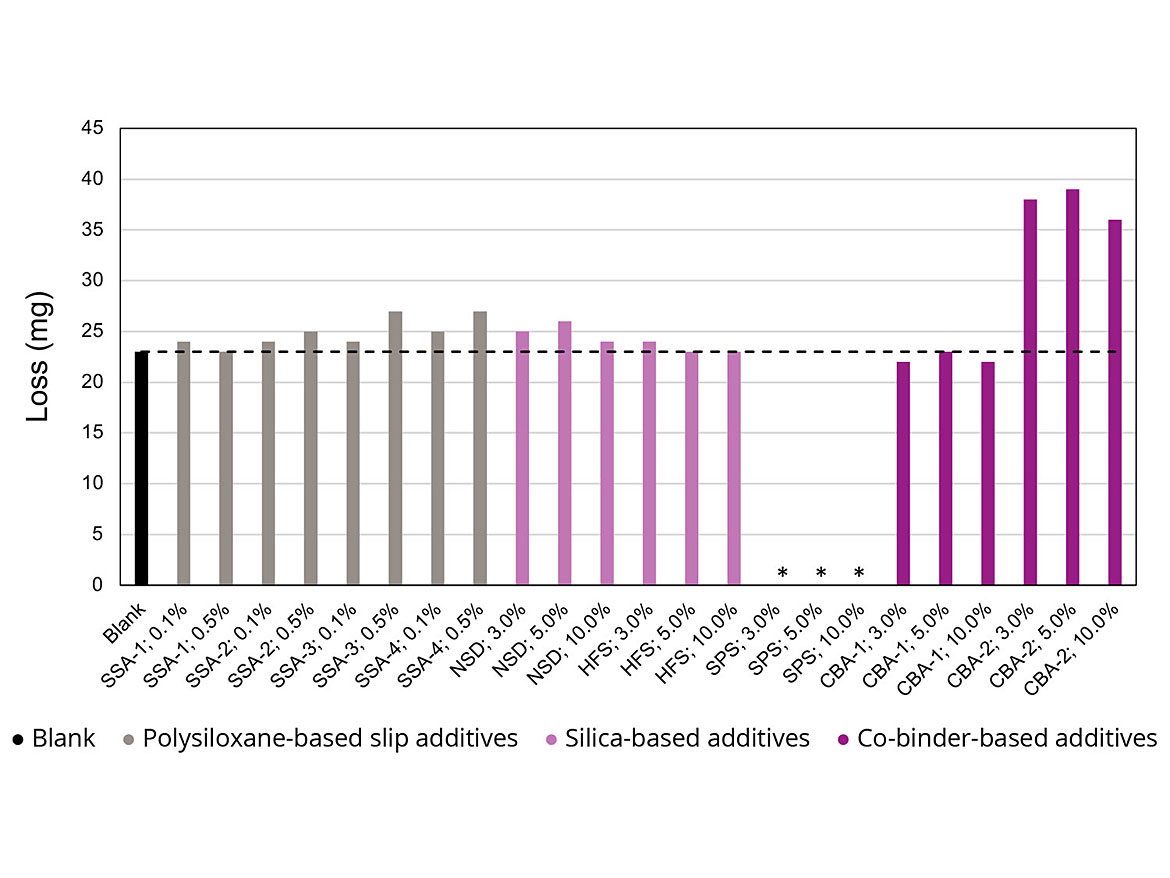

Figure 2 shows the weight loss measured during the Taber abraser test for the coatings prepared based on 1K-WB System A. The results show that almost all polysiloxane-based SSA additives slightly decrease the weight loss values of the coatings containing these additives, showing their moderate effects on improving abrasion resistance. In the coatings containing nanosilica dispersion-additive NSD, the weight loss values are significantly low, indicating good abrasion resistance. The highest abrasion resistance is found for the coating containing 10.0 wt.% NSD. It seems these nanosilica particles, especially in high addition levels, significantly contribute to withstand severe abrasion. The addition of hydrophobic structure-modified fumed-silica HFS improves the abrasion resistance, although the effect of the addition level remains unclear. The abrasion resistance of the coatings is improved by increasing the addition level of spherical-precipitated silica particles SPS from 3.0 to 10.0 wt.%. It seems the addition of polyester-dispersion-cobinder additive CBA-1 to the coatings does not contribute to the abrasion resistance. The interpretation of the resulting weight loss values by the addition of this cobinder to the system remains challenging. As expected, adding CBA-2 can decrease the weight loss resulting from the abraser test. By increasing the addition level of CBA-2 from 3.0 to 5.0 wt.%, the abrasion resistance behavior of the resulting coating becomes comparable to that of NSD-containing coatings. However, a comparison of the weight-loss values reveals that increasing the CBA-2 level from 5.0 to 10.0 wt.% decreases the abrasion resistance, which could be attributed to the high brittle characteristics resulting from the high addition level of this high Tg cobinder additive.

Figure 3 shows the weight loss measured during the Taber abraser test for the coatings prepared based on 2K-WB System B. As expected, this 2K-WB System B generally provides higher abrasion resistance compared to 1K-WB System A. The results show that the additives SSA-1‒4, NSD, HFS, and CBA-1 do not have significant effects on the abrasion resistance of the prepared coatings. It seems the high crosslink density of this 2K-WB system provides a coating with high resistance against Taber’s abrasion. The weight-loss values of the coatings containing spherical-precipitated silica-based additives (SPS) do not provide conclusive data for further interpretations. As shown, the addition of polyurethane polyol-based additive CBA-2 decreases the abrasion resistance of the prepared coatings. It seems adding this cobinder with a high Tg value of ~120 °C introduces brittle characteristics to the prepared coatings.

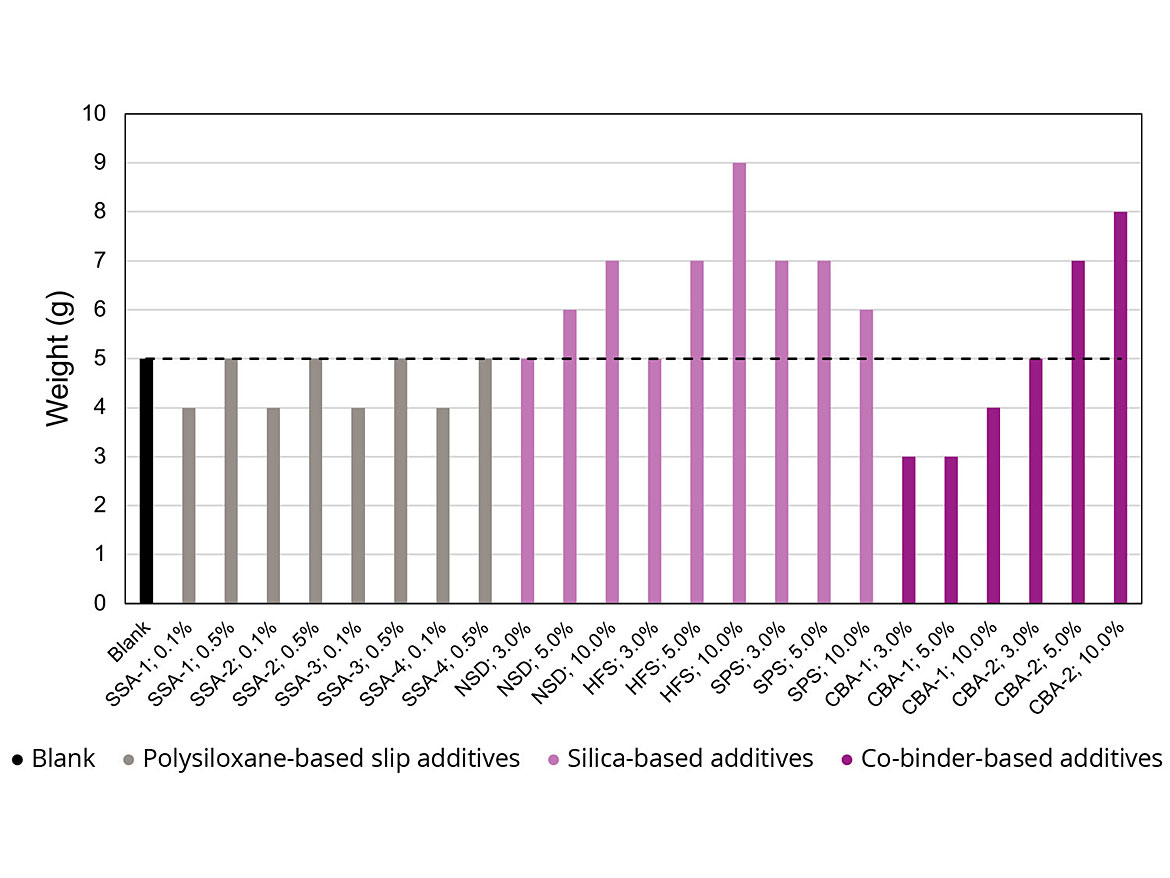

The Taber shear test results for the coatings prepared based on the 1K-WB System A are shown in Figure 4. The higher weight values for damaging the coatings indicate better abrasion resistance characteristics. SSA-1‒4 additives do not have a significant effect on the abrasion resistance against the Taber shear test. However, all silica-based additives NSD, HFS, and SPS, as well as high-Tg cobinder CBA-2 improve the abrasion-resistance values. A good correlation between the addition level of NSD, HFS, and CBA-2 additives and the resulting abrasion resistance is demonstrated. The addition of cobinder additive CBA-1 decreased the abrasion resistance in this system.

Figure 5 shows the Taber shear test results for the coatings prepared based on 2K-WB System B. In this system, the addition of SSA-4 at 5.0 wt.% and CBA-1 at 10.0 wt.% slightly improves the abrasion resistance of the prepared coatings. Due to the high variability in the results achieved for the coatings containing spherical precipitated silica SPS, a consistent interpretation is not possible. In general, these Taber shear test results do not provide conclusive information regarding the effect of additives in this coating system.

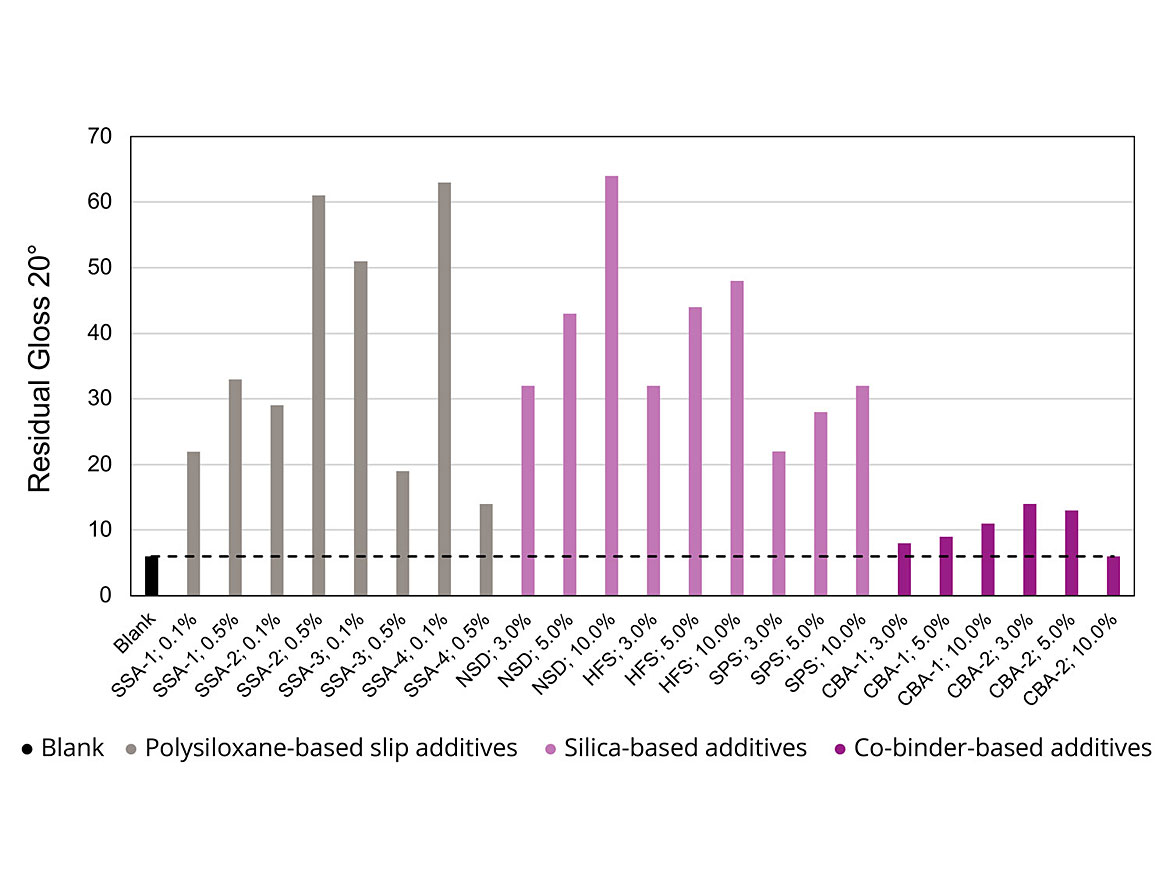

Figure 6 shows the gloss 20° values of the coatings prepared based on 1K-WB System A measured after an abrasion test by a Martindale (James Heal) instrument. As shown, most of the additives used can improve the abrasion resistance of the coatings. Specifically, adding 0.5 wt.% SSA-2, 0.1 wt.% SSA-4, or 10.0 wt.% NSD provides the highest abrasion resistance to the coatings prepared based on this system. In general, cobinder additives CBA-1 and CBA-2 show the lowest effects on the Martindale abrasion resistance values. As an example, the abrasion test results for the blank coating sample and the coating containing 0.5 wt.% SSA-1 additive are shown in Figure 7. The surface of the coating containing additive shows better gloss retention after Martindale abrasion compared to that of the blank sample.

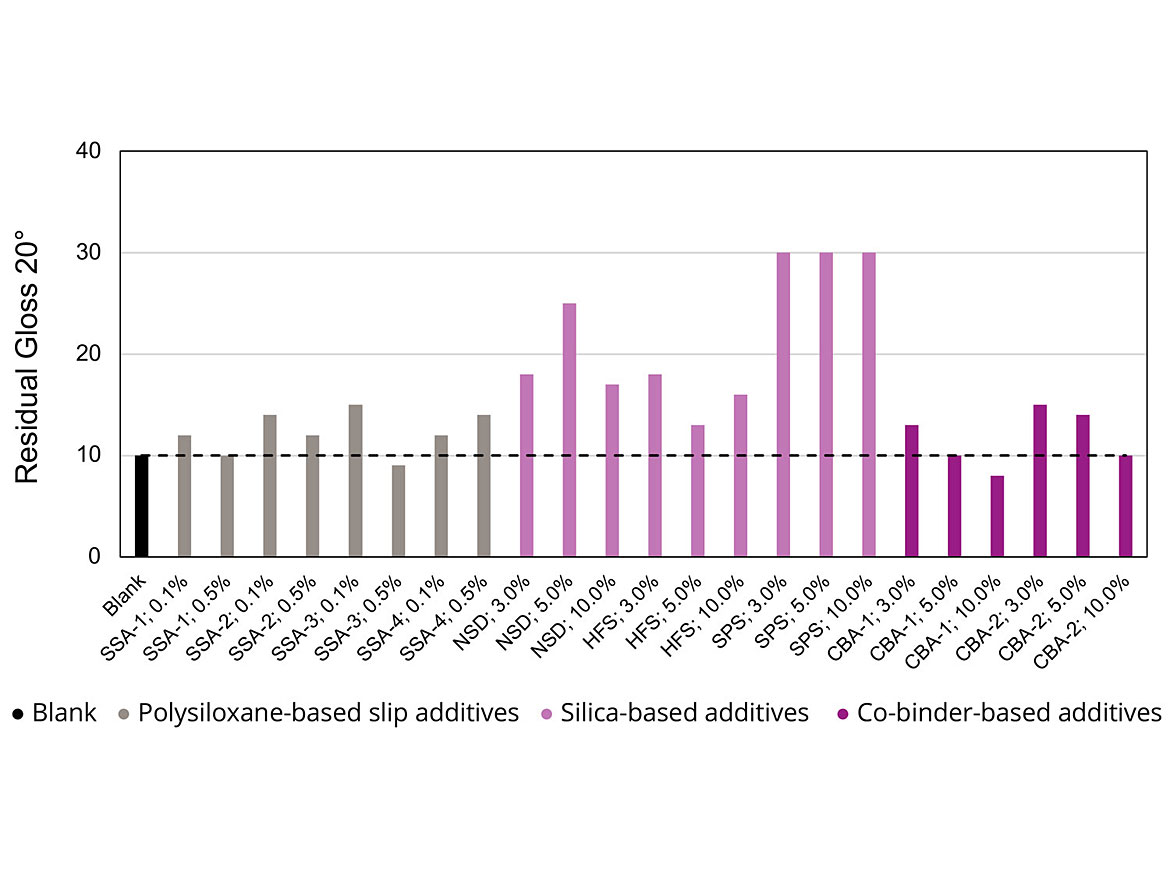

Figure 8 shows the gloss 20° values of the coatings measured after abrasion tests by a Martindale (James Heal) instrument for the coatings prepared based on 2K-WB System B. As shown, adding SPS, spherical precipitated silica, to the coating based on 2K-WB System B can improve the abrasion resistance. It seems the addition level of SPS does not affect the abrasion resistance results created by the Martindale instrument. Also, adding 5.0 wt.% NSD, nanosilica dispersion, improves the abrasion resistance in this 2K-WB System B.

Figures 9 and 10 show the gloss 20° values of the coatings measured after abrasion tests by a crockmeter (SDL Atlas) instrument for the coatings prepared based on 1K-WB System A and 2K-WB System B. As shown in Figure 9, adding nanosilica dispersion (NSD) additive can significantly improve the abrasion resistance of 1K-WB System A. Also, a good correlation between the addition level of NSD and the resulting abrasion resistance is demonstrated. As shown in Figure 10, SSA-1 in 0.5 wt.% level and SSA-4 in both 0.1 and 0.5 wt.% levels, can slightly improve the abrasion resistance in 2K-WB System B. It seems other additives tested have no effects or adverse effects on the abrasion resistance in this system.

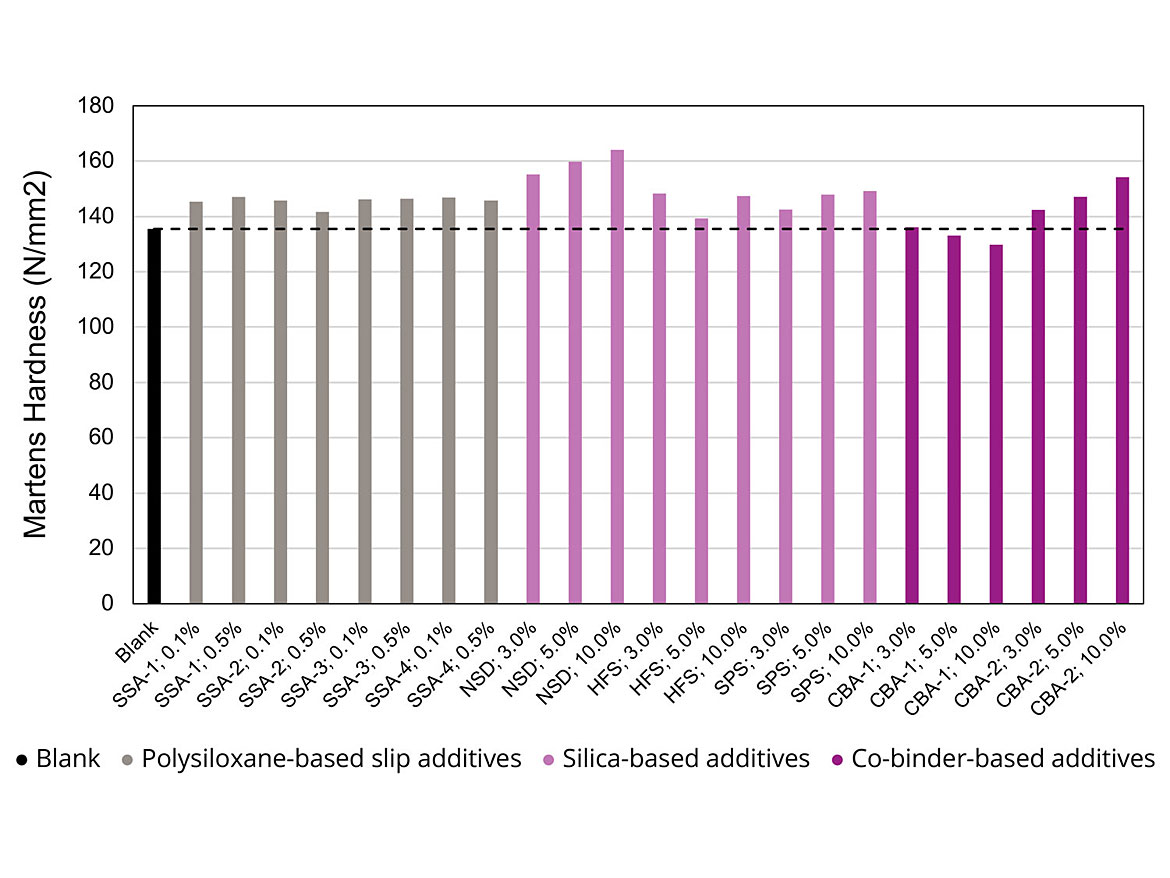

The Martens hardness is an important factor characterizing the elastic and plastic properties of the materials derived from the indentation test. Martens Hardness could potentially be linked to the abrasion resistance properties of materials. Figures 11 and 12 show the Martens hardness values of the coatings measured after abrasion tests by a Martens (Fischer GmbH) instrument for the coatings prepared based on 1K-WB System A and 2K-WB System B. As shown, adding high-Tg polyurethane-polyol additive CBA-2 can improve the Martens hardness of all the systems tested. This improvement is much more significant in 1K-WB System A compared to that of 2K-WB System B. This observation is because of the significantly harder characteristics of 2K System B compared to 1K System A. Interestingly, a good correlation between the addition level of CBA-2 and the improved Martens hardness values is also observed.

Conclusions

The goal of the present research was to achieve a good understanding of the effects of coating additives on the abrasion resistance of waterborne coatings. Two waterborne coatings 1K-WB System A and 2K-WB System B were selected as the main systems to investigate the abrasion resistance using different test methods. To make the formulations, polysiloxane-based slip additives SSA-1-4 were used at 0.1 and 0.5 wt.% levels calculated on the total solid contents of the formulations. Silica-based additives NSD, HFS, and SPS as well as cobinder additives CBA-1 and CBA-2 were used at 3.0, 5.0, and 10.0 wt.% levels calculated on the total solid contents of the formulations. The abrasion results showed high dependency on the coating systems. As expected, highly crosslinked 2K-WB System B demonstrated better abrasion resistance compared to 1K-WB System A. Although different additives could significantly affect the abrasion resistance in 1K-WB System A, they did not have significant effects on the abrasion resistance of 2K-WB System B. This could be related to the increased hardness of these highly crosslinked coatings, which made the effects of additives less significant. As durability becomes an increasingly important performance parameter to improve in waterborne coatings, this study demonstrated that there is no one additive technology to improve durability across all types of test methods. This study demonstrated that specific solutions vary depending on the formulation and specific test method used to assess abrasion resistance.

*This paper was presented at the 2023 Waterborne Symposium in New Orleans.

References

1 Patrick, J. F.; Robb, M. J.; Sottos, N. R.; Moore, J. S.; White, S. R. Polymers with autonomous life-cycle control. Nature 2016, 540 (7633), 363-370.

2 Standard Terminology Relating to Wear and Erosion. ASTM: G40-22.

3 Baydoun, S.; Arnaud, P.; Fouvry, S., Modelling adhesive wear extension in fretting interfaces: An advection-dispersion-reaction contact oxygenation approach. Tribology International 2020, 151, 106490.

4 Handbook of Coating Additives. 2nd ed.; CRC Press: 2002.

5 Hofmann, D. C.; Andersen, L. M.; Kolodziejska, J.; Roberts, S. N.; Borgonia, J.-P.; Johnson, W. L.; Vecchio, K. S.; Kennett, A. Optimizing Bulk Metallic Glasses for Robust, Highly Wear-Resistant Gears. Advanced Engineering Materials 2017,19 (1), 1600541.

6 Krefetz, S. B.; Fischer, T. E. Wear of yttria-doped α-alumina: effects of grain-boundary composition and machine stiffness. Wear 1997, 211 (1), 141-145.

7 Coronado, J. J.; Holguín, C. A.; Rodríguez, S. A. Sliding wear of weld layers with application to cane mill shaft rebuilding. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology 2010, 224 (12), 1283-1291.

8 Pulecio, S. A. R.; Farias, M. C. M.; Souza, R. M. Finite element and dimensional analysis algorithm for the prediction of mechanical properties of bulk materials and thin films. Surface and Coatings Technology 2010, 205 (5), 1386-1392.

9 Lancaster, J. K. Abrasive wear of polymers. Wear 1969, 14 (4), 223-239.

10 Mergler, Y. J.; Kampen, R. J. v.; Nauta, W. J.; Schaake, R. P.; Raas, B.; Griensven, J. G. H. v.; Meesters, C. J. M. Influence of yield strength and toughness on friction and wear of polycarbonate. Wear 2005, 258 (5), 915-923.

11 Yim, C. I.; Lee, K. J.; Jho, J. Y.; Choi, K. Wear resistance of some modified ultra-high molecular weight polyethylenes and its correlation with tensile properties. Polymer Bulletin 1999, 42 (4), 433-440.

12 Hemler, S. L.; Charbonneau, D. N.; Beschorner, K. E. Predicting hydrodynamic conditions under worn shoes using the tapered-wedge solution of Reynolds equation. Tribology International 2020, 145, 106161.

13 Bhutta, M. U.; Khan, Z. A. Wear and friction performance evaluation of nickel based nanocomposite coatings under refrigerant lubrication. Tribology International 2020,148, 106312.

14 Presser, V.; Krummhauer, O.; Kailer, A.; Nickel, K. G. In situ monitoring and depth-resolved characterization of wet wear of silicon carbide. Wear 2011, 271 (9), 2665-2672.

15 Paint and Coating Testing Manual: 15th. Edition of the Gardner-Sward Handbook. ASTM International: 2012.

16 https://www.jamesheal.com/instrument/martindale.

17 https://www.taberindustries.com/taber-rotary-abraser.

18 https://www.taberindustries.com/shear-scratch-tester.

19 https://www.taberindustries.com/crockmeter.

20 Standard Test Method for Abrasion Resistance of Textile Fabrics (Martindale Abrasion Tester Method). ASTM: D4966-12(2016).

21 Shahdad, S. A.; McCabe, J. F.; Bull, S.; Rusby, S.; Wassell, R. W. Hardness measured with traditional Vickers and Martens hardness methods. Dental Materials 2007, 23 (9), 1079-1085.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!