Addressing Our U.S. Supply Chain Crisis: What’s Next?

Jason Kutchma, Creatas Video+ / Getty Images Plus, via Getty Images

shaunl, E+, via Getty Images

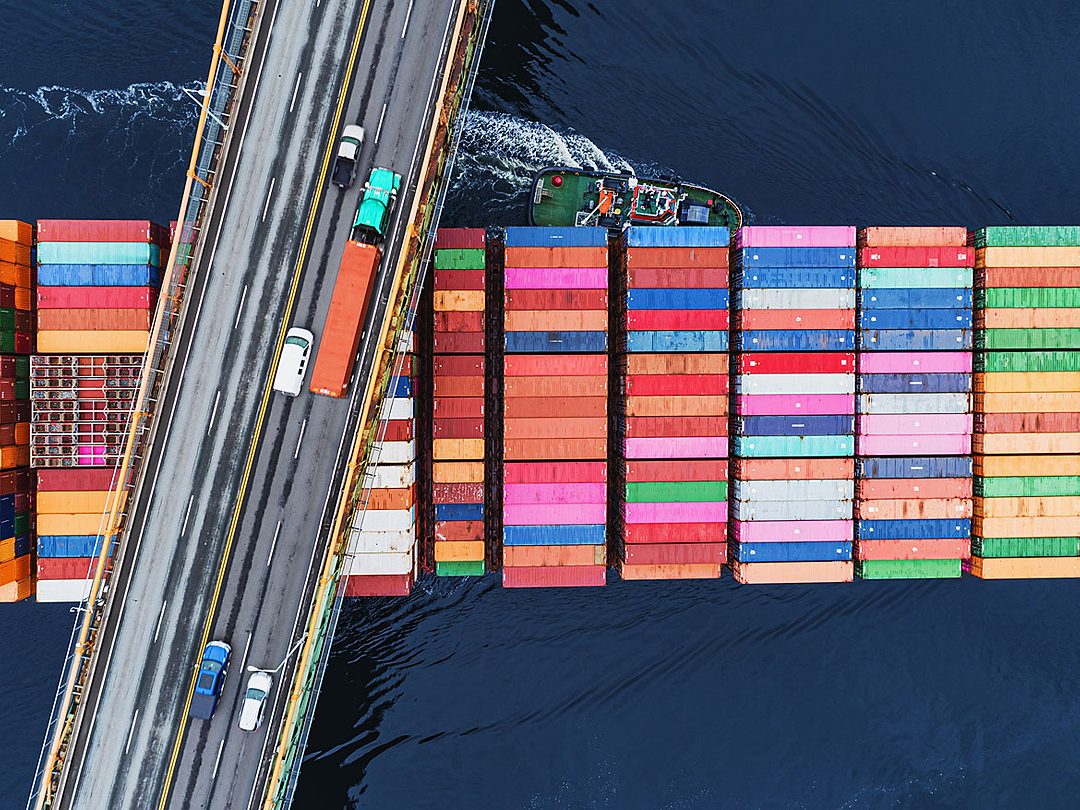

The supply chain crisis, which began as a shortage of shipping containers and labor at certain west coast port facilities, quickly morphed into a long-term breakdown of the nation’s supply chain infrastructure. Labor shortages and increased demand for goods were significant but largely unavoidable components of the breakdown. Chemical distributors supporting the paint and coatings industry were right in the middle of these supply chain challenges, many of whom lead the way in solutions to keep products moving.

The National Association of Chemical Distributors (NACD) represents these important companies who process, formulate, blend, re-package, warehouse, transport, and market chemical products for over 750,000 industrial customers across the United States. They were among the industries considered essential during the COVID-19 crisis. They are a vital link to ensure a vibrant paint and coatings industry keeps running, no matter the challenges that face the industry.

More than 60% of NACD’s chemical distributor members support the paint and coatings industry, providing crucial products needed for coatings for life-saving equipment such as ventilators and vital signs monitors, cleaning products, mold/mildewcide treatments, the interior coating of steel, and aluminum food and beverage cans that ensure food safety, and many others. As a result, any shipping delays distributors experience have broad implications for companies in the paint and coatings industry as well as the entire chemical supply chain.

Many factors contributed to the supply chain crisis. Some, like severe COVID-19 restrictions in states with the nation’s largest ports that experienced labor shortages, were a natural result of a country grappling with managing and responding to the global pandemic.1 Government stimulus increased consumer spending on goods at a time when fewer services were available, resulting in a surge in imports. International shipping became much less reliable, with delays for some shipments reported to be as much as 150 days.2 By October 2021, freight prices had skyrocketed more than 400% along the most critical routes, and many shelves were left empty across the country.

There were also factors contributing to the breakdown that were, in fact, avoidable. For countless years, businesses and industries dependent upon an efficient and well-functioning supply chain have been asking lawmakers to address our antiquated port infrastructure, rail access, competition, pricing issues, and a growing truck driver shortage left too long unaddressed.

Fuel was added to the fire when ocean carriers – who cemented historic, record-breaking profits during the pandemic3 – saw an opportunity amidst the crisis and began levying exorbitant detention and demurrage fees on customers, despite shippers being physically unable to retrieve freight from the ports due to congestion, labor shortages, and limited port hours. Carriers began refusing transport of hazardous substances essential to everyday health and safety, and inventories of chemicals began falling for the first time since the great recession. It then became apparent that continued lengthy delays could not only contribute to slowing economic recovery, but also jeopardize public health.

Congress Cracks Down on Bad Ocean Shipping Carrier Practices

In early 2021, the chemical distribution industry was increasingly rocked by supply chain woes, which left our members frustrated, helpless, and looking for answers. NACD took charge immediately and began forming a coalition of trade associations that were also impacted by the congested ports. The coalition engaged with hundreds of lawmakers and their staff on Capitol Hill, and ultimately gained major bipartisan support in the House of Representatives and the Senate. On June 16, 2022, President Biden signed S. 3580, the Ocean Shipping Reform Act of 2022 (OSRA), into law, empowering the Federal Maritime Commission (FMC) to hold ocean carriers accountable for high shipping rates, anti-competitive practices, and arbitrary decision-making.

OSRA will address many of the elements of the perfect storm that helped to spur and exacerbate this crisis4, including, among other improvements:

- Stopping international ocean carriers from unreasonably declining American cargo.

- Directing the FMC to investigate ocean carrier business practices and apply enforcement measures.

- Shifting the burden of proof for demurrage and detention charges to the international ocean carriers.

- Requiring international ocean carriers to report to the FMC regarding how many empty containers are being transported.

- Stopping retaliation by international shipping companies against exporters and importers.

- Improving management of chassis, the specialized trailer used to transport ocean containers over the road.

While OSRA is critical and NACD members are urging its full and speedy implementation, the supply chain crisis won’t be fixed overnight, and it will take more than OSRA to end it. Infrastructure improvement, freight rail reform, and policies that put more truck drivers on the road are critical. Equally important are general government policies that champion businesses rather than create more challenges for companies already reeling from the pandemic, the supply chain crisis, a tight labor market, and rising inflation and interest rates.

The United States chemical distribution industry has been trying for too many presidential administrations and sessions of Congress to get a comprehensive infrastructure package passed to modernize port infrastructure. While the most recent package will help modernize our country’s infrastructure, there was little set aside to modernize our port systems, certainly not enough to modernize America’s ports for the long-term.

Ongoing Rail and Trucking Problems Hurt Distributors Too

Once cargo is moved off ships, timely, safe, and reliable freight rail and truck transportation is essential in ensuring products reach their final destination on time. Many United States class I railroads operate as near-monopolies and have little oversight over their rates to transport cargo. The NACD has long advocated for a strong and engaged Surface Transportation Board (STB); the federal agency overseeing our nation’s railroads. Recently, the STB has begun to make progress in addressing freight rail issues, but rail service is continuing to worsen as railroads are reducing their service.

In April, NACD member Hawkins, Inc., testified before the STB on behalf of businesses who have experienced the impacts of deteriorating rail service. Hawkins, who has seen reduced outbound shipment availability from their freight rail carrier and increased transit times of five to 14 days on average, underscored the significance that reliable, efficient, and affordable rail service has on ensuring chemical distributors can successfully run their businesses and serve their customers. In one example, a facility was forced to shut down production for two days while waiting for raw materials. When the freight finally arrived, not only had production been severely impacted, but the company incurred demurrage fees after being overwhelmed by the number of cars in its serving yard due to the railway’s irregular service.

Over-the-road transportation of goods by truck is also in a precarious situation in the United States. According to the American Trucking Associations (ATA), the trucking industry is responsible for moving about 72.5% of all freight. The nation’s long-acknowledged truck driver shortage is directly impacting chemical distributors’ ability to provide on-time product delivery now more than ever. Moreover, the slow replacement of retiring drivers due to commercial drivers not being permitted to move goods between states until they have reached 21 years of age is contributing to the shortage.

The truck driver shortage has been approaching critical mass for years. The NACD has worked to get the DRIVE-Safe Act, and smart programs like it, passed to increase the pool of eligible drivers. Congress did take a positive step by including the Safe Driver Apprenticeship Pilot Program in the Infrastructure Investment and Jobs Act of 2021. The pilot program allows employers to establish an apprenticeship program for certain 18- to 20-year-old drivers to operate commercial vehicles in interstate commerce, but more is needed.

Businesses Need Solutions, Not More Problems

Compounding all these issues are roadblocks being thrown up by lawmakers and regulators at the state and federal levels. Adding to the critical lack of truck drivers, state-level rules are now in effect in California that could force two-thirds of truck drivers serving our largest ports in Los Angeles, Long Beach, and Oakland off the road, at least temporarily. The truck driving industry has traditionally relied on independent contractors. California Assembly Bill 5 (AB5) sets up a three-part test that truckers must pass to be considered contractors. If those conditions are not met, they must be categorized as employees. Other states may soon consider similar legislation.

Issues are belabored more by the reincarnation of the superfund tax included in the infrastructure bill, which has added tax liability and compliance uncertainty to the list of challenges facing companies manufacturing, moving, and using chemicals. Adding to the list, the United States Environmental Protection Agency (EPA) has amended the Risk Management Program (RMP). The RMP is comprehensive and robust, and has proven effective in preventing chemical accidents. Amending RMP to include new requirements seems wasteful and unnecessary when outreach, compliance assistance, and strict enforcement of existing regulations could more effectively advance the program.

Far too many shippers are still experiencing price increases that exceed the inflation rate, long delays to receive their freight, and the end result of lost revenues. It is still increasingly difficult to ship hazardous material products, and delays for imports of materials defined as hazardous increased.

OSRA passage is a welcome first step to addressing the supply chain crisis. Shippers across the country are eagerly anticipating the swift implementation of the law. However, it’s clear that there is no single solution to solve our ongoing supply chain crisis. A full spectrum of issues must be addressed to truly fix America’s broken supply chain, help to reinvigorate our economy, and keep critical goods moving across the United States and throughout the world.

References

1Import surge, labor shortages worsen LA-LB congestion. The Journal of Commerce online. https://www.joc.com/port-news/terminal-operators/import-surge-labor-shortages-worsen-la-lb-congestion_20210112.html.

2 NACD Shipping Survey. https://www.nacd.com/pub/?id=946BF4F8-EB96-66EE-5167-8756416B4C5C.

3 Hillstom, K. Shipping giants under fire for record profits, fees as pandemic continues. The Hill. Feb. 2, 2022. https://thehill.com/business-a-lobbying/592397-shipping-giants-under-fire-for-record-profits-fees-as-pandemic-continues

4 President Biden Signs Cantwell-Championed Ocean Shipping Reform Act, U.S. Senate Committee on Commerce, Science, and Transportation. https://www.commerce.senate.gov/2022/6/president-biden-signs-cantwell-championed-ocean-shipping-reform-act.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!