Vapor Degreasing – The Perfect Finish

Surface preparation is essential to achieving a superior finish. Metal components must be perfectly clean before painting, coating, plating, welding or any other subsequent processing. It is also essential to simply improve the component’s final appearance. To achieve a high-quality surface for finishing, cleaning is an important step that ensures components are ready for the next stage of manufacture. Vapor degreasing using modern, highly advanced cleaning fluids makes the process simple, consistent and sustainable and results in spotlessly clean parts.

Here we look at the process and why it is one of the most comprehensive and effective cleaning methods to achieve an excellent surface for finishing.

The Mechanics of Vapor Degreasing

Parts cleaning is essential to many industrial processes. Even the smallest amount of surface contaminant whether it’s machining oil, grease, adhesives, wax, marking inks, fingerprints or other particulates, can impair a finishing method and result in parts not functioning reliably. It is therefore critical to find a long-term cleaning process that produces a meticulously clean substrate while also addressing other burdens like sustainability and cost-effectiveness. Many companies are renewing their interest in the benefits of vapor degreasing over other cleaning procedures because it is a highly-effective way to clean parts and tackles associated production concerns.

Vapor degreasers are effective, small, fast, economical, sustainable, worker safe and extremely flexible cleaning machines. They are highly effective at trapping and removing soils from even the most complex and intricate component designs and geometries.

A vapor degreasing machine is a closed-loop system. Used within it, is a specialized low-boiling, non-flammable fluid as the cleaning agent. The cleaning fluid constantly re-purifies and recycles for hundreds of cycles before it needs refreshing. This limits fluid use, reduces waste generation and lowers disposal costs.

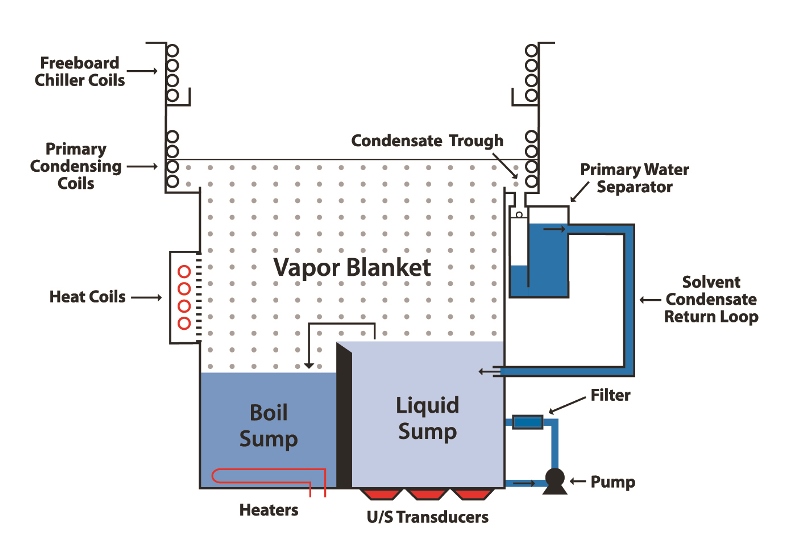

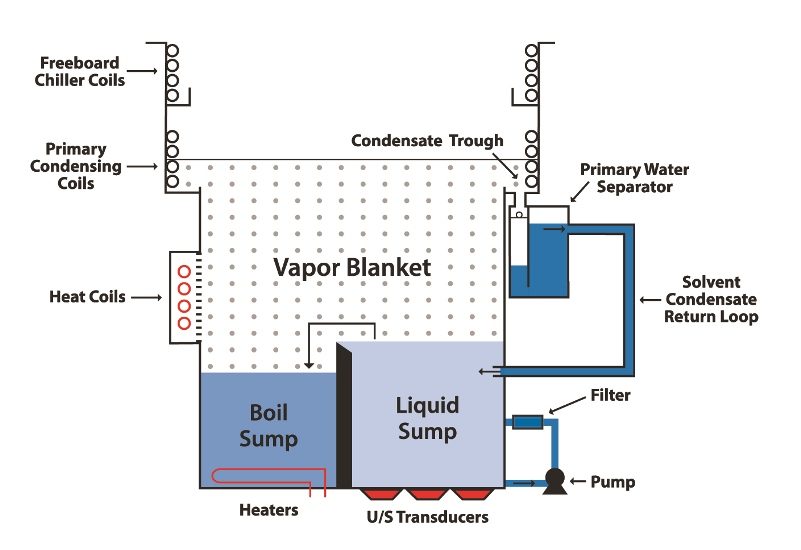

The machine contains two chambers: the boil sump and the rinse sump. In the boil sump, the cleaning fluid heats the fluid into vapors. The low-density, warm vapors rise upwards in the machine. They are then trapped by a layer of refrigeration which creates a temperature inversion. The vapors then condense back into liquid form and return into the cleaning machine to be re-used.

Once cleaned, the parts mechanically transfer to the internal rinse sump for final rinsing in a pure, uncontaminated fluid. The parts come out clean, dry, spot-free and immediately ready for the next step in the process.

How to Select a Cleaning Fluid

When using a vapor degreaser to clean and finish parts, it is important to select a cleaning fluid that encompasses all the requirements needed to make the process successful and efficient. Using a sustainable cleaning fluid is an important ‘cog in the machine’. If the wrong solution is selected the long-term goal of effective, sustainable cleaning may not be met.

Effectiveness

Cleaning and surface preparation are now more challenging due to the increased use of miniaturized parts and complex geometries. Smaller components have tighter tolerances, which brings increased complications when manufacturing and finishing.

The cleaning fluids used within the vapor degreasing system have multiple chemical properties that are advantageous to this critical cleaning. However, it is important to look for certain cleaning fluid features. They should have a low surface tension and a very low viscosity. These properties help to wet every surface getting into and out of tiny spaces to remove contaminant and residue. Modern cleaning fluids should also offer high solvency which enables rigorous surface cleaning and displacement of stubborn soils. It also needs to be heavy and dense, helping to dislodge particulate from the parts. But, because the cleaning fluid is engineered for specific applications, delicate parts are easily cleaned and dried without damage.

Sustainable Solution

Cleaning and finishing processes are subject to an increasing number of environmental regulations. It is not just the cleaning fluid itself that is scrutinized, but also the method in which it is disposed of. Vapor degreasing effectively addresses both of these concerns.

Considering the long-term environmental impact is important in manufacturing operations. The cleaning fluid used should not only perform reliably but must also be ‘green’. Look at the cleaning fluids safety sheets, does it include any potentially harmful or environmentally damaging substances like Trichloroethylene (TCE) and n-propyl bromide (nPB)? If so, opt for a more environmentally-sound version. For example, cleaning fluid based on HFE (hydrofluoroether) or HFO (hydrofluoroolefin) formulations.

Many modern vapor degreasing chemistries are ozone-friendly and comply with environmental directives including European F-Gas and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) legislation. Importantly, they offer improved eco-friendly properties without compromising the performance.

Another environmental benefit of vapor degreasing fluid is its capacity for recycling. It is used over and over again for hundreds of cycles before it needs refreshing or replacing. Additionally, it concentrates the soil and contaminants as it works, minimizing the amount of hazardous waste generated. Other cleaning processes like aqueous cleaning require the wastewater filtering, distillation, deionizing, and osmosis prepping for disposal. Also vapor degreasing does not need precious natural resources like water or copious amounts of energy to clean. Therefore, it helps conserve water and reduce fossil fuel consumption, resulting in a lower total carbon emission and less greenhouse gas output.

Putting Worker Safety First

Worker safety is a priority for any business, it is therefore critical to choose a finishing method that is safe to use. When studying the safety sheets for any environmental implications, also look at whether the cleaning fluid is non-flammable and what the toxicity rating is.

The Threshold Limit Value (TLV) is a commonly used rating for toxicity and is measured in parts-per-million (ppm). High numbers, those approaching 1,000 ppm (the highest rating possible), indicate a safer cleaning fluid, lower numbers specify a greater risk. A cleaning fluid that necessitates greater scrutiny has a TLV of 10-25 ppm. It’s best to use a cleaning fluid with a TLV of 200 or higher.

New sustainable cleaning fluids used in a vapor degreaser have impressive worker exposure limits. The Permissible Exposure Limit (PEL) or designated time limit that workers should be exposed to a chemical is much higher. Permissible exposure levels for sustainable fluids are about 200-250 ppm. Compared with TCE which has a 100-ppm PEL or nPB that is rated at just 0.1 ppm, sustainable cleaning fluids are significantly better for the safety of exposed workers.

Cost Implications

Of course, having a cleaning process that addresses worker safety and environmental concerns is all very well, but if it is not cost-effective it is just not viable.

Vapor degreasing is low on energy consumption, which saves money. The cleaning fluid is also re-used many times without the waste disposal associated with other cleaning methods - another cost-saving. It cleans quickly and effectively, and parts come out of the vapor degreaser clean, dry, spot-free and ready for the next stage in the production process increasing the overall throughput and productivity.

Additionally, in many cases, the modern cleaning fluids can be used in existing equipment, with the same operating methods. After emptying and cleaning the vapor degreaser of the previously fluid, many of the replacement cleaning fluids can be “dropped in” into the machinery without a significant change to the cleaning process.

Cleaning is a critical step to achieve a quality surface finish. The most efficient and sustainable solution is through vapor degreasing and highly advanced cleaning fluids. This process is a cost-effective way to not only ensure parts are perfectly clean but also tackles worker safety, regulatory requirements and environmental concerns.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!