Moody's Coatings Conundrums: Answer to Saul’s Un-Sellable Formulation

Saul Vance’s boss was telling him that the formulation that Saul had developed and tested was being pulled from the market, and Saul couldn’t understand why. In order to save costs, his company’s purchasing director, Lois Bidder, had resubmitted his formulation with one important change; she had taken out the ketone solvent and replaced it with PM acetate. Since Saul had done all the work and shown that the properties of the coatings changed very little with the change in the two different solvents, why was the formulation pulled from the market? Why did this change in solvent make the formulation no longer sellable, even though the properties were so similar?

The formulation was no longer sellable because of the way the government requires coatings companies to report the Volatile Organic Compound (VOC) content in paint. Strict government regulations require that paint formulations sold in certain regions be below certain VOC levels. Saul was aware of these regulations and had formulated the system to meet the strict VOC regulations in the area it was to be sold. Saul had formulated the system to be just under the required maximum VOC limit. However, when Lois Bidder made the substitution of solvents, the amount of reported VOC of the formulation changed. Even though the solvents were replaced on a weight basis, because the VOC calculation is based on a density calculation, the differences in densities of the two solvents raised the VOC to above the limit where it could be sold. The formulation VOC was now above the maximum allowed.

This problem relates to a common misconception in the industry, and specifically with new purchasing agents. Lois Bidder purchased solvents by the pound from her suppliers. Lois was always looking for ways to reduce this cost, but she didn’t realize that the company reports VOC by the pound of VOC per gallon of coating.

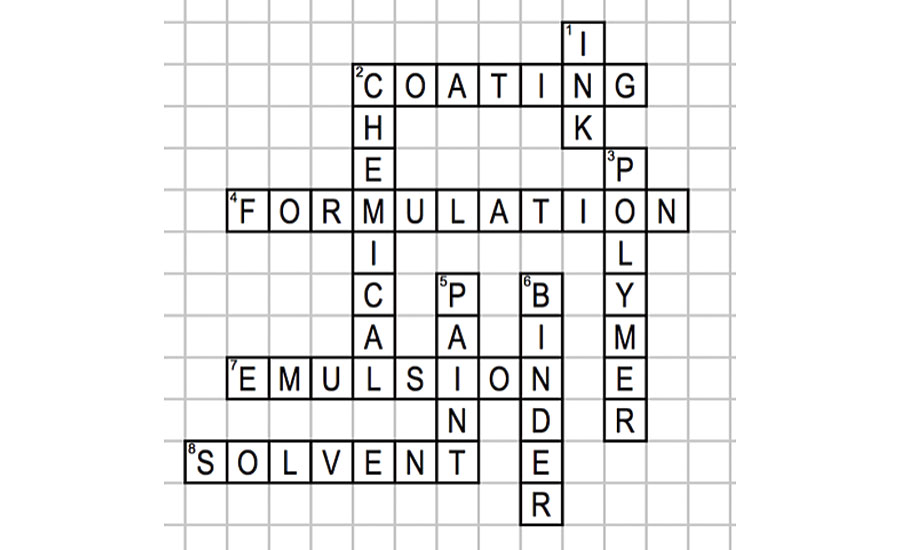

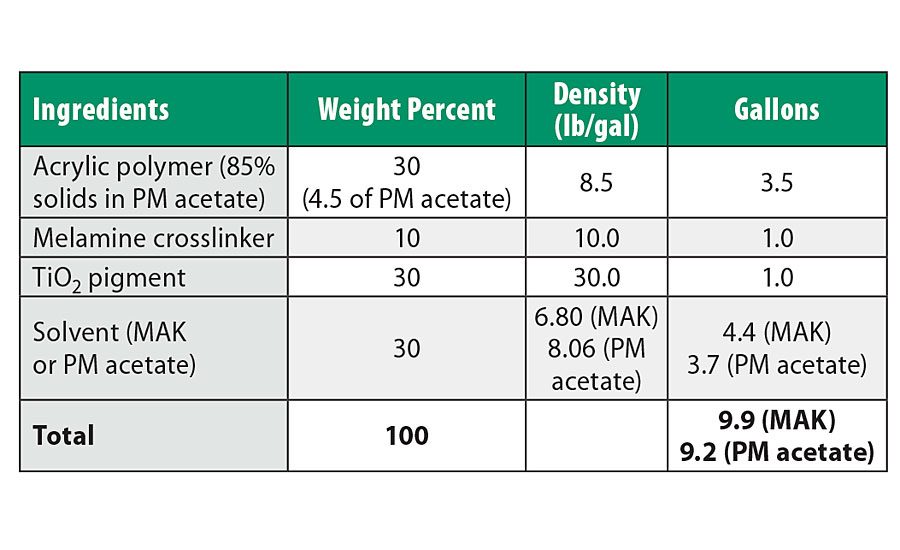

Even though Saul’s formulation was more complicated, for purposes of illustration a simple formulation below shows how changes in solvent can impact the VOC calculation. The major components of the formulation are acrylic polymer in solvent, melamine crosslinker, TiO2 pigment, and added solvent. If we assume that the formulation contains no water and no exempt solvent, and that the only VOC is from the solvents added and already in the acrylic resin, we can show how changing one solvent for another impacts the VOC of the formulation.

The simple formulation in the table shows the ingredients in weight percent and the corresponding density. The calculation of gallons of paint is weight percent divided by the density of the ingredients. The VOC changes depending on which solvent is used.

Lois understood that the change in solvent makes no difference in the weight percent solvent for the two formulations, but she didn’t understand how the difference in density of the solvents impacts the calculation of the total number of gallons and thus, the VOC of the coating. VOC regulations are reported as mass per volume; in this case as pounds of VOC per gallon of paint. This VOC calculation done for regulation purposes gives an advantage to low-density solvents by increasing the volume of the formulation.

If again, we only consider the VOC contributed by the solvents in the formulation, we can see that lower-density solvents, even though equal on a weight basis, give an advantage in calculation of lower total VOC in the coating formulation.

The original coating formulation that Saul had put together with MAK has a VOC of:

wt of volatiles (lb)/volume of paint (gal) = (30 lb MAK + 4.5 lb of PM acetate)/9.9 gal = 3.48 lb/gal of VOC

However, by changing the solvent from MAK to a more dense solvent like PM acetate, the VOC is:

wt of volatiles (lb)/vol of paint (gal) = (30 lb of PM acetate + 4.5 lb of PM acetate)/9.2 gal = 3.75 lb/gal of VOC

In this simple example, this solvent change resulted in an increase of VOC of almost 8%. The increase was enough to now make the formulation above the VOC limits for selling the paint.

Not only had Lois Bidder’s attempt to save money caused the paint to be unsellable, she had actually increased the cost of the coating, doing exactly the opposite of what she was attempting. Lois bought solvents from her suppliers at a cost per weight of solvent. However, the company then sells these formulated coatings by the gallon. Instead of looking at the cost per gallon of the formulation, Lois had only considered reducing the cost per pound of solvent used in the formulation. By making this change in solvent, the total volume of paint made dropped by over 7%. This meant that there were 7% fewer gallons of paint that could be sold. Since the difference in price of the two solvents was less than the cost of 7% fewer gallons sold, she had actually increased the cost of the formulation.

For information on how to calculate VOC’s, see: Brezinski, J.J. Manual on Determination of Volatile Organic Compounds in Paints, Inks, and Related Coating Products, 2nd Edition, ASTM Manual Series MNI 4, ASTM, Philadelphia, PA 1993.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!