Siltech Features Organo-Functional Silicones

Using proprietary technologies, Siltech develops, manufactures and markets a full and unique line of organo-functional silicones, which you can learn about at Booth 714. With more than 30 years of experience and two manufacturing facilities, the company offers a broad portfolio of cationic, quaternary, alkyl and reactive silicones for many markets.

Products emphasized at the Eastern Coatings Show include Silmer TMS Di-50, which is a silane functional polymer that reacts with condensation-cured systems. This ability to react into curing systems includes delivering secondary cure in some UV-cured resins. Inclusion of this silicone into the network provides excellent durability, shine, water repellency and release properties to many surfaces including concrete, roofing, rubber, countertops, etc. The reaction with itself or other condensation reactive groups can be facilitated with acid or base, but will proceed slowly without catalysis.

Another focus product at ECS 2019 is Silmer ACRN Di-100, a novel tetrafunctional UV-curable monomer. This product can be cured as the only resin, but typically is co-reacted with other acrylate polymers and UV-curing systems for coatings, plastics, resins and other applications in order to incorporate a silicone moiety into the polymer structure. When co-reacted during the polymerization stage, Silmer ACRN Di-100 improves the surface and physical properties of the polymers. These benefits include better release, slip, anti-blocking, stain and mar resistance, surface smoothness, strength, impact resistance and flexibility.

Silmer ACRN Di-100 is more reactive and more compatible with organic resins than the more traditional Silmer ACR Di-100 product, resulting in faster reactions, clearer formulations and better property improvements. Silmer ACRN Di-100 is also low in odor.

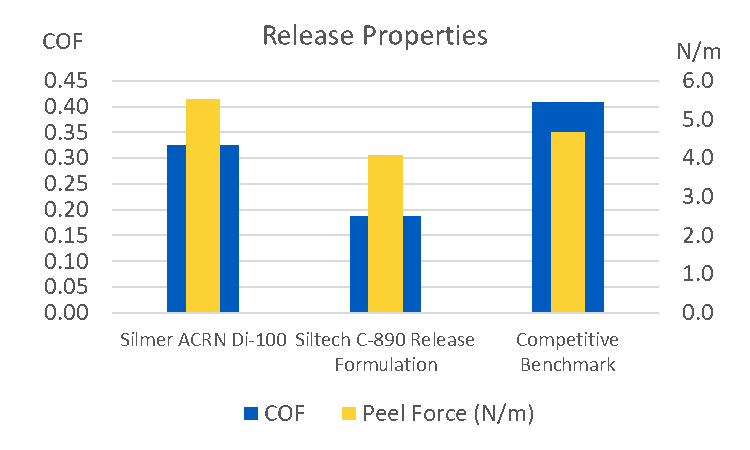

Silmer ACRN Di-100 was compared to Siltech C-890, a formulated release additive, and a competitive benchmark all at 3% in an epoxy acrylate UV-curable formulation. The Siltech C-890 gave more release but was cloudy in the formulation. Silmer ACRN Di-100 gave good release while remaining clear (Figure 1).

A third product the company is highlighting at ECS 2019 is Silmer UACR Di-1010, a urethane silicone hybrid that provides flexibility, strength and particularly elongation in UV systems.

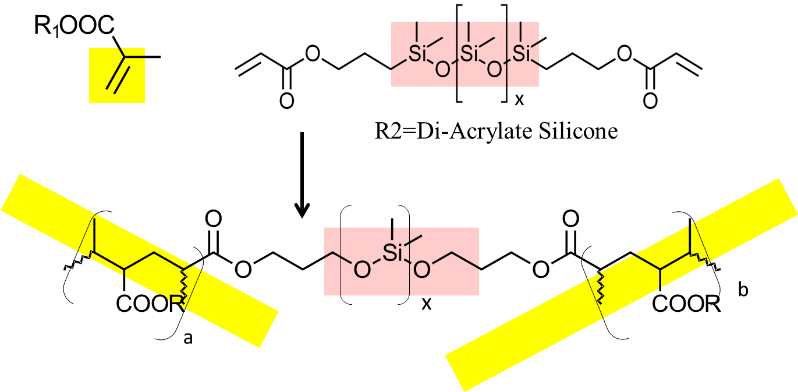

Due to the way acrylate groups cure, the silicone backbone of a standard acrylate di-functional silicone is not built into the backbone. This is indicated in yellow in Figure 2. Rather the silicone is contained in the crosslinks, or side chains, of the resin, shown in pink in Figure 2.

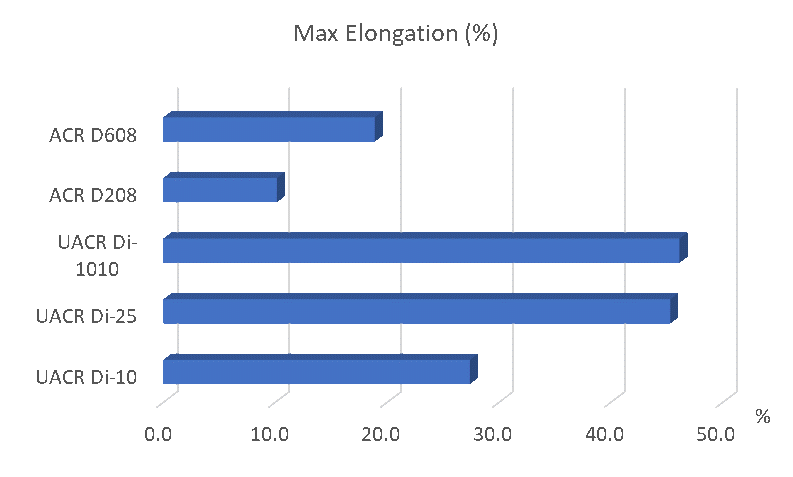

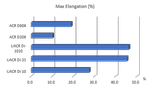

This minimizes the typically large elongation increase of the flexible silicone polymer. In these cases, elongation is typically a few percent compared to around 100% for condensation-cured polymers where the silicone is in the backbone. Using Silmer UACR di-functional products such as Silmer UACR Di-1010, the company has achieved elongations of up to 48% (Figure 3).

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!