Terrazzo Flooring – a Historic Solution to Modern Flooring Issues

The Background

Terrazzo flooring is a composite – a mix of resin with aggregates, which give the product such variety in its design.

Intended to be a durable, hard-wearing and highly decorative flooring solution, the resin is mixed with colored marble, granite chips or other approved aggregates such as glass. During production, the mix is ground and polished to reveal the pattern of the aggregates, which contrasts with the colored epoxy.

Terrazzo can be laid in a number of thicknesses depending on requirements, typically 8-12 mm.

The advantages of such a product are well-known; terrazzo can be traced back to ancient Egypt with the more modern form we know now dating back hundreds of years to Italy.

As well as being aesthetically pleasing, terrazzo flooring is durable, wear-resistant, stain resistant and designed to be easily cleaned – the flooring offers a seamless finish, easy to clean and with limited numbers of joints.

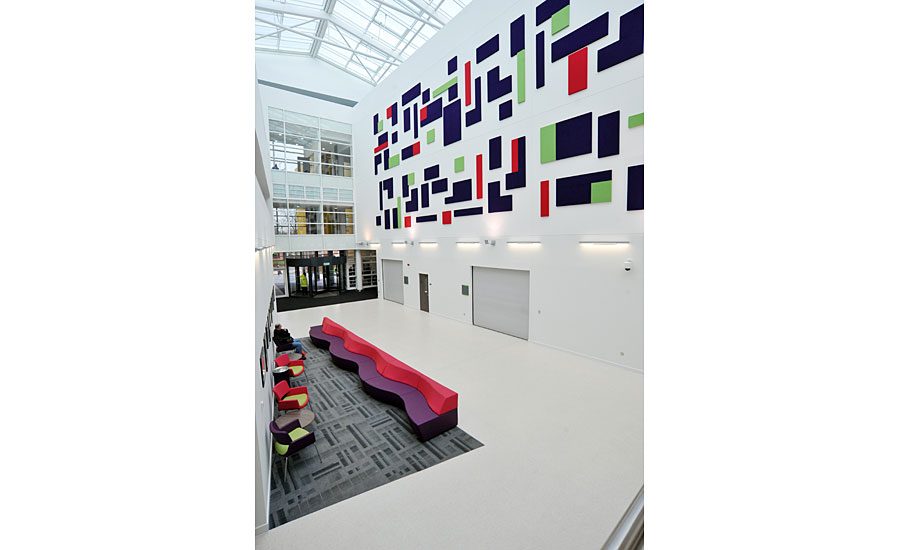

Such a system is ideal for use in areas and facilities with high foot traffic, such as airports, stadiums, schools and hospitals. Due to the unique aesthetic finish of these systems, terrazzo is often used in high-profile developments.

Sherwin-Williams supplied more than 1,000 sq meters of epoxy terrazzo to the Greenwich Visitor Centre at the Old Royal Naval College. The project required a fresh and modern floor covering that would be durable enough to withstand the daily footfall it would receive.

The solution was RS Terrazzo, a four-part component, heavy-duty epoxy system containing decorative aggregates and stones marble. In a method common to this system, the terrazzo was laid at 10 mm thick, ground and polished down to 8 mm and finished with a clear surface seal.

Terrazzo generally has excellent slip resistance underfoot in dry conditions, antimicrobial and antistatic properties suitable for use in industries such as pharmaceutical, electronic, food and healthcare sectors.

Once installed, the product was a seamless floor covering free from joints (apart from any movement joints) and with its bespoke Stirling Grey base, with black, grey and white glossy marble detail it met the requirements of the £6million development in Greenwich.

This project highlights the key benefits of a terrazzo flooring system, benefits which are well understood but perhaps not specified as often as they should be.

In the United States, terrazzo flooring systems are commonly utilized, and the large, high-specification developments of the Middle East can commonly be found featuring customized terrazzo systems. Many parts of Europe, though, have been slow to specify this system.

The Benefits

There can be the higher initial cost of installing a terrazzo flooring system, which may cause a less expensive system to be preferred. However, this can be a false economy. Data from the U.S. body the National Terrazzo & Mosaic Association (NTMA), demonstrate these savings in a stark light.

For instance, the average installed cost per square foot for vinyl sheets was found to be £29 approx ($2.98 per sq ft), while the cost per meter for epoxy terrazzo was £140 ($14 per sq ft), almost five times more. However, vinyl floor sheets would require replacing every 18 years, but epoxy terrazzo every 40 years. The cost of maintenance for epoxy terrazzo was found to be £5.00 per sq m ($0.50 per sq ft), compared to £13.90 per sq m ($1.39 per sq ft) for vinyl. Overall, the annual cost per square meter for the two flooring types was £16.60 ($1.66) for vinyl and £8.50 per sq m ($0.85 per sq ft) for epoxy terrazzo, almost half the cost.

For large projects, this is a significant difference. When Sherwin-Williams worked with the Salford Royal NHS Trust, it supplied more than 2,000 sq meters of RS Terrazzo, with a bespoke aggregate blend introducing white, grey and black marble and granite to give the end product a personalized finish. Over its lifespan, the cost difference for a project like this will be significant.

There are stark differences in the life expectancy of terrazzo flooring versus other systems – 20 to 25 years is common, with simple re-polishing or re-sealing – using water-based products – perhaps after 10 years.

It is not just cost savings that mean specifiers are turning to terrazzo flooring solutions. Its green credentials are also impressive.

Green Credentials

Thin-set epoxy conforms to the EU’s solvents Emissions Directive, which will add to the green credentials of the systems. As the finished flooring is non-porous, it means moisture and radon gas cannot penetrate, promoting healthy indoor air quality.

It is produced from processed resin binders, pigments and fillers, and more than 50 per cent from recycled materials such as glass, or leftover granite or marble chips from stone processing plants. The aggregate itself often comes from local sources, reducing the carbon footprint of a build, whereas other traditional flooring systems may use imported stone or other materials.

The installation process itself also means there is very little waste – the terrazzo prepared for installation can be measured accurately and as much or as little as is required can then be prepared.

Once in place, the nature of the product means it commonly lasts the lifetime of a building, removing the need for costly replacement and further waste. If repairs are required, these can be done relatively efficiently.

Terrazzo floors are crucial when considering green credentials such as the Leadership in Energy and Environmental Design (LEED). LEED considers issues during construction including use of recycled content, local materials, waste management, reduction of odor-emitting materials and innovative design – terrazzo floors fit the bill here perfectly.

Specifiers and architects like terrazzo floors as it gives a coatings company the opportunity to sit down with them and ask, ‘what do you want?’ The solution may be entirely customized, and a design that may never be repeated thanks to the range of options from the aggregate to the epoxy resin matrix which can also be colored via pigments.

Truly bespoke options can be created with endless design options in terms of both color and aggregate matrices, such as glass, marble, granite and mother of pearl.

Take the Central Library in Manchester. As part of a three-year overhaul, the Grade II listed building underwent a multi-million-pound improvement, using material from a local supplier and to a special color pallet to mirror the neo-classical design features. The seamless nature of the floor, supplied by Sherwin-Williams, ensured a flat, continuous surface was achieved, and the project received praise from the city council for its attention to detail.

As architects and specifiers demand longer-lasting products with ever-greater green credentials, terrazzo is clearly an ideal solution.

Terrazzo has its roots in technology hundreds of years old, yet for those looking to specify correctly from the outset, with longevity in mind as well as return on investment and aesthetics, it remains a thoroughly modern choice.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!