Innovation in Intelligent, Highly Effective Corrosion Inhibitors

In the EU, it is estimated that 786,000 workers are currently exposed to toxic, carcinogenic hexavalent chromium.1 However, developing effective, chromate-free alternatives has proven to be a key challenge for the coatings industry, as well as the end-product industries that rely on effective corrosion protection.

REACH legislation has been pushed back from September 2017 to January 2019 to allow the performance gap between the current industry-standard and safer, chromate-free inhibitors to close. In that time, an innovative, smart product has hit the market: an inhibitor that replaces toxic chemicals with disruptive micro-reservoir technologies, creating ‘smart’ coatings that last longer.

Safer, Smarter Corrosion Control

Hexigone Inhibitors moved their research away from iterations of current substitutes and explored smart-release vehicles that can hold onto chemicals that were previously incompatible with coatings. The result is a highly effective corrosion inhibitor – Intelli-ion® – which outperforms hexavalent chromate under laboratory conditions.

The Intelli-ion pigment is a patented micro-reservoir system that senses ionic activity related to corrosion and sequesters the corrosive ions into the reservoir, while simultaneously releasing the highly effective inhibitor to protect at a coating defect or at the cut-edge. The smart functionality of the pigments allows the coating to protect itself in a smarter way, leading to greater longevity and longer periods of time before the end product needs repairing or replacing, thereby far exceeding any competitors on the market.

The original technology was developed by Dr. Patrick Dodds in the Swansea University Corrosion Research Group, led by Professor Geraint Williams. Following the discovery, Hexigone Inhibitors was incorporated and awarded the Armourers and Brasiers Venture Prize as well as the Brian Mercer Feasibility Award. Also identifying the company’s exceptional innovation in engineering, the Royal Academy of Engineering awarded Hexigone an Enterprise Fellowship in order to develop the inhibitor further.

“This is a significant discovery and shows how the U.K. is still a driving innovation force in industry,” — Bill Bonfield, professor and chair of the Armourers and Brasiers Venture Prize judging panel.

Accelerated Testing Through In-House Technology

Hexigone uses a scanning Kelvin probe (SKP), specially built by the team (alongside Professor Hamilton McMurray and Professor David Worsley) to detect the state of the metal beneath a coating without touching it. The SKP (Figure 1) allows Swansea University researchers to test the electrochemical effects of their newly synthesized inhibitor systems within 24 hrs, rather than 500 hrs as was previously the case.

The SKP uses a gold reference probe that is vibrated perpendicular to the test piece in a sinusoidal manner. The coated sample acts as one of the plates in a parallel plate capacitor, with the gold probe forming the other plate. The passing of current is detected by the electronics and nullified via a lock-in amplifier. This results in the Kelvin potential, with the test piece moving, and thereby produces a spatially resolved map of the coated sample.

Dependent on the failure mechanism or the substrate, a map is produced every 30 min to an hour, giving time-dependent maps from which rates and mechanisms can be elucidated. The test piece can be any metallic substrate that is coated or uncoated, and the equipment can even detect a corrosion map of a fingerprint on spent bullet casings, where traditional methods rely on organics that get burnt off during firing.

Protect End Products for Longer

According to Hexigone CEO and Founder, Patrick Dodds, “The system has been shown to prevent the onset of corrosion for over 24 hrs compared to less than 2 hrs for the current market leader. We have also been able to demonstrate that the rate of corrosion can be slowed down significantly once it has started. This is by far the best result seen in 15 years of research on this topic.”

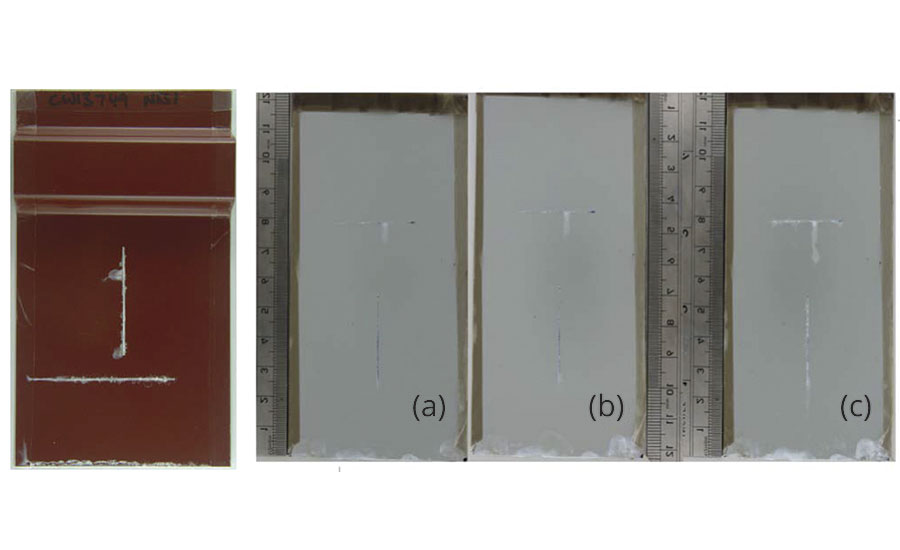

Examples of spatially resolved maps of cathodic delamination of HDG substrates can be seen in Figure 2. As the corrosion progresses, there is a sharp drop in the free corrosion potential, giving a cathodic delamination front, from which distance vs time points can be taken for rate calculations. The new pigment system showed a high level of performance at Generation 1, with increased protection offered by the Generation 2 product, with no visible failure 4 days post-test initiation.

Further standard electrochemical testing was performed on the modes of protection, and it was found that the system showed:

- A decrease in difference between the potentials of the intact and delaminated coating;

- Under-film moderation of pH;

- Insoluble salt formation with any dissolved metal ions in the under-film electrolyte;

- Activation at high pH and film forming at the cathodic oxygen reduction front; and

- Thin film formation over any bare metal.

A Drop-In Replacement for Industrial Coatings

The excellent laboratory results from the Generation 1 product led to assessing the pigments within an industrial coating system alongside European manufacturers. The pigments were offered as a drop-in replacement, with no reformulation, and assessed for humidity and ASTM-B117 (Figures 3 and 4).

The pigments show a high level of inhibition when in the industrial coating system, not only protecting to a high level at the defect but offering an increased protection at the cut edge. The inhibiting system showed no creep from the scribe at 1,000 hrs. The technology was patented in 2015. Further analysis and testing has shown compatibility across a range of coating systems, always offered as a drop-in replacement.

Further to the accelerated testing results, the coatings were analyzed for their physical performance, and the independent UKAS-accredited test results showed a similar or increased coating integrity in the physical test, accredited to the acidic nature of the new pigment system. The system can also be alkaline in nature, dependent on the curing conditions of the coating system.

Conclusion

Coating manufacturers will soon be forced to replace chromate inhibitors, and while extensive research into alternatives has certainly taken place, there is the remaining demand to do so with pigments with better or at least comparable performance attributes.

Intelli-ion offers a safer, smarter way to replace traditional toxic chemicals and heavy-metal-containing substitutes. It can be easily incorporated into existing coating products, and could even enhance certain coating properties.

The ‘smart-release’ technology is environmentally sound, economical and outperforms the market-leader in independent laboratory tests. Following excellent results in the coil-coated steel market, Hexigone is looking to work with innovative, R&D-driven coating manufacturers and expand research within the aerospace and automotive sectors.

References

1 3IARC IARC Monographs on the Evaluation of Carcinogenic Risks to Humans. Chromium (VI) Compounds. Volume 100C Lyon, France: International Agency for Research on Cancer, 2012.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!