Finding a Path to Smart Paints, Adhesives, Films and Alloys using Smart Materials

Smart materials are becoming an important part of our future, and in many cases they are right under (or above) our noses today. Every-day examples range from your child’s forehead thermometer to your sunglass frames.

Children’s forehead film thermometers are inexpensive and convenient tools for measuring approximate temperatures based on the surface reaction of materials in a layered film. But what makes it “smart”? The particles that are layered and positioned in the thermometer film are specially selected inks and polymer particles that change their reflective properties based on the surface temperature. The resulting effect creates the appearance of intelligence by providing a viewpoint of perspective to the user. The particles are individually performing a specific localized reaction to a stimulus that is fundamental to the particles themselves. In this case the attribute of the particles is that they change their optically reflective properties based on temperature. This gives the user the apparent viewpoint that the film appears to become “smart” by providing a reading of temperature in color and numerical information. It almost can appear to be magic – but it is actually physics.

Another smart material example that we use every day is built into most of our sunglass frames through the use of shape memory alloy material. One of the most amazing and spectacular metal alloys in use today is nickel titanium (also known as Nitinol). One of the properties of this material is the ability to program a shape of the metallic structure under extreme temperatures. The resulting shape can be recalled through material memory by reheating the object to a nominal temperature, which will cause realignment of the particles to the original programmed shape. Other uses for Nitinol alloy is a form of wire called muscle wire. The wire shape can be formed in such a way that it effectively contracts its length like a muscle when heated. Another principle of the material is that it is electrically conductive. Therefore the programmable stimulus can be in the form of electrical energy and perform motion based on a computer signal. This is very important for the advancements in robotics and industrial automation.

What is a Smart Material?

So what is a smart material? The generally accepted definition is, “A material that exhibits one or more properties that can be significantly changed in a controlled fashion by external stimuli.” You could therefore generalize this definition to say that everything and every one of us is a smart material. But, in the context of material science today we focus our definitions to the nonobvious and spectacular. I want to make this point because the perception of spectacular and common knowledge is an ever-changing spectrum. In the not-too-distant future we will find potential to control molecules in ways that we never dreamed to be possible. An example of this is in the ever-expanding discoveries based on DNA and protein modeling of matter. In my opinion we are all examples of the spectacular nature of smart materials that have been programmed by DNA coding becoming organisms and humans. We are also continually programmed by external stimuli reacting and responding to ever-changing situations. The fact that we gain a greater understanding than we previously had does not make these now-known facts less spectacular.

For example, the most basic discovery of moving particles based on temperature was shown clearly through the invention of the Galileo Thermometer in the 1600s. This was an amazing accomplishment of a physical set of attributes based on object density and fluid-object displacement. The temperature can be observed by the user in a self-contained temperature acquisition and display device. A truly amazing invention for its time and still respected today. However, we don’t think of this as spectacular in today’s high-tech world.

Many scientific discoveries become obsolete over time, and industries lose interest in the scientific fundamentals of the inventions and discoveries that once were thought to be magical and spectacular.

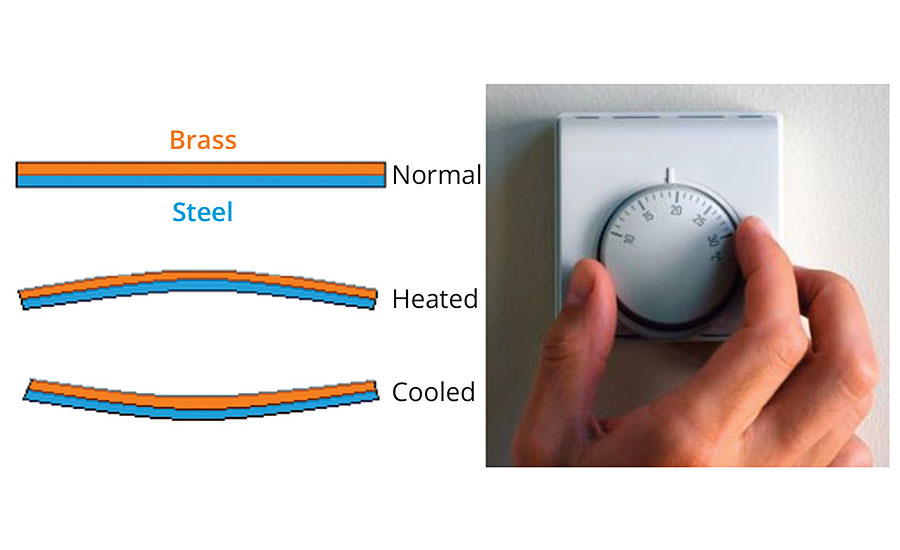

Another example of a scientific principle that is still widely used today but is becoming obsolete is the principle of bimetal displacement based on temperature. This technology is one of the world’s simplest thermostat inventions (Figure 1). The movement of the two different metals occurs due to each metal having different attributes based on temperature. The net effect is a predictable movement of the combined structure of bimetal commonly known as a bimetal strip. You can imagine that the movement of the heated and cooled bimetal shape could be connected to an ON/OFF switch where the switch is pushed upward to turn ON the air conditioner and pushed downward to turn OFF the air conditioner. This is the basic structure of almost all mechanical thermostats made over the last hundred years. One interesting note related to this “magical” phenomenon is that we do not think of this solution as a smart material in today’s modern world. I would ask you to ask, “Why?” or “Why not?” I feel the answer is perception of reality, and we love what is newly discovered. We think of it as “magic” and therefore “smart.”

FIGURE 1 » The principle of bimetal displacement based on temperature (the thermostat), could at one time have been considered “smart” technology.

So, where is the world of discovery heading and what should we look for as significant smart materials for the future?

- Polymers

- Ceramics

- Carbon forms

- Mixed-mode hybrids

Smart Materials

Polymer chemistry advancements have become part of our everyday lives. The addition of long-chain water-soluble polymer lubricant strips have helped in the act and art of shaving by allowing a renewed application of lubrication in every stroke. The apparent structure of the strip is perceived as a magic piece of plastic to most users as they just wet the surface and it continually provides lubrication over hundreds or thousands of shaving strokes (Figure 2). The material in the form of polymer molecules forms chains that transfer from the strip to the skin, which provide a smooth surface coating for the razor blades to float over while the cutting surface removes the unwanted hairs, therefore reducing pain during shaving.

FIGURE 2 » Lubricant strips on razors demonstrate polymer chemistry advancements that have become part of our everyday lives.

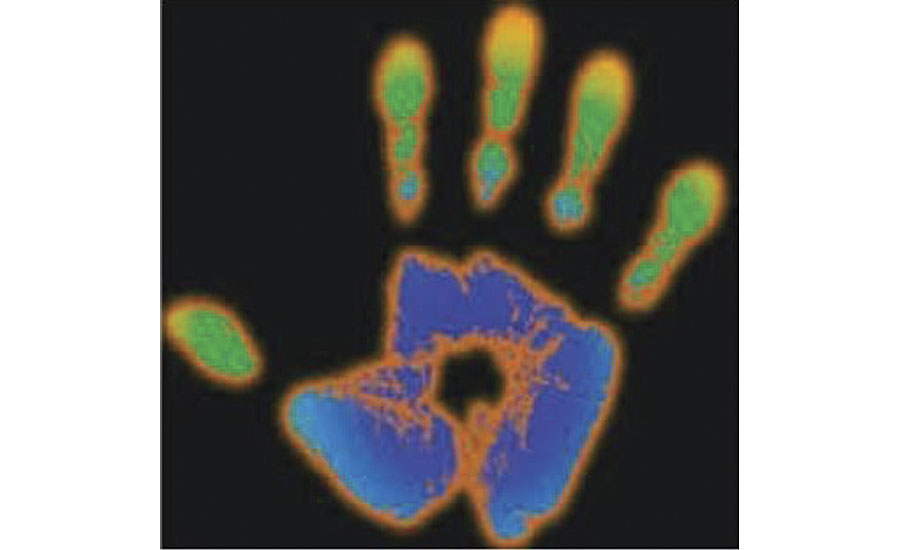

Advancements in polymer research have also provided the ability to create specific molecular features or attributes that can be manufactured to provide various states or forms. One type of polymer that can become “smart” utilizes the property of thermochromatic transition states (Figure 3). This technology is seen in the previous example of the children’s thermometer film but can also be used to create color changes in items dating back to the mood ring of the 1970s. In today’s world we can utilize these properties to allow polymer particles to become transparent based on temperature rise or temperature fall. This can be used to create multilayered signage including building materials that can change color or become invisible.

FIGURE 3 » One type of polymer that can become “smart” utilizes the property of thermochromatic transition states.

Another version of smart materials based on temperature is a hybrid material application that utilizes conductive electrical current flow to visually indicate a quantitative energy meter directly on the side of a battery (Figure 4). Thermochromic inks can be used along with a resistive film coating. The display will change based on a battery’s voltage. The energy must be sufficient to create a proportionate current flow through the film in order to generate enough heat to display 100% full. The lower the voltage – the lower the bar graph as seen by the observer. Smart particles provide a power meter with no computer involved.

FIGURE 4 » Smart particles provide a power meter directly on the side of a battery.

Piezoelectric elements can be formed as films, wafers or crystalline particles that can be used as sensors and that can also become actuators (Figure 5). The physical properties of the surface can be energized to move based on the voltage level and polarity of the stimulus provided differentially across the surface of the crystal. This property can be used to make a movement, a beeper or a speaker. Another interesting property of the material is that the inverse operation is possible as well. This means that the same device that is a speaker can also operate as a microphone or a displacement vibration sensor. It can also generate small amounts of energy during vibration to yield energy harvesting.

FIGURE 5 » Piezoelectric elements can be formed as films, wafers or crystalline particles that can be used as sensors and that can also become actuators.

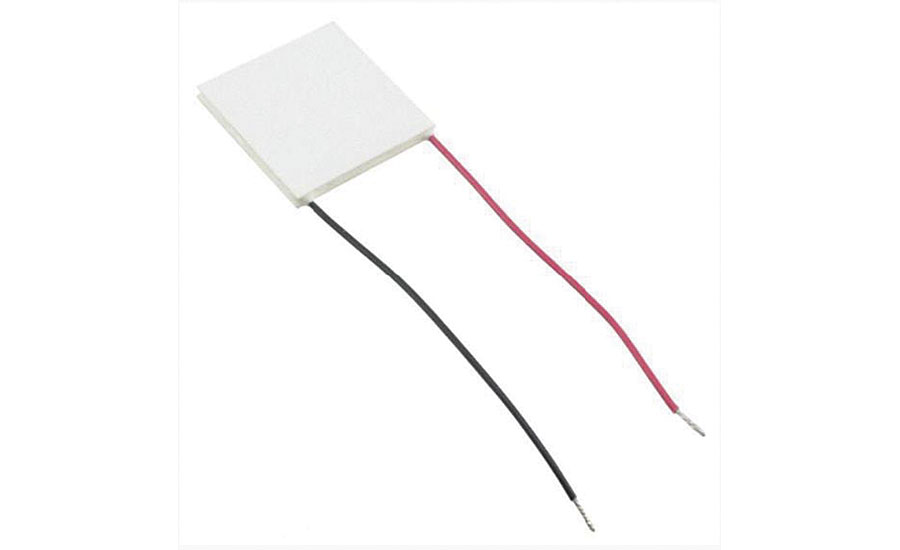

One of the principles of all matter is that there is some level of temperature nearly everywhere in the universe. This brings an interesting property of a device called a Peltier device or thermoelectric cooler. The primary function of the special silicon junction is that you can provide a voltage potential that creates a current flow, and the material attributes create a cooling effect on one side of the device while creating a heating effect on the other side (Figure 6). Another spectacular attribute is that the device can also generate a small amount of energy if you provide a temperature differential with sufficient heat and delta temperatures. Another seemingly magical example of potential energy harvesting.

FIGURE 6 » The special silicon junction of the Peltier device can provide a voltage potential that provides a current flow that creates a cooling effect on one side of the device while creating a heating effect on the other side.

Organic LEDs are providing the ability to provide an electrical stimulus across a junction of material that can create a transmission of light at a specifically programmed wavelength (or color) (Figure 7). The interesting part of this material advancement is that the particles can be manipulated in such a way to create a nonplanar or flexible surface. This will evolve into silk-screened TV screens and spray-on digital signage as active billboards.

FIGURE 7 » Organic LEDs can provide an electrical stimulus across a junction of material that can create a transmission of light at a specifically programmed wavelength (or color).

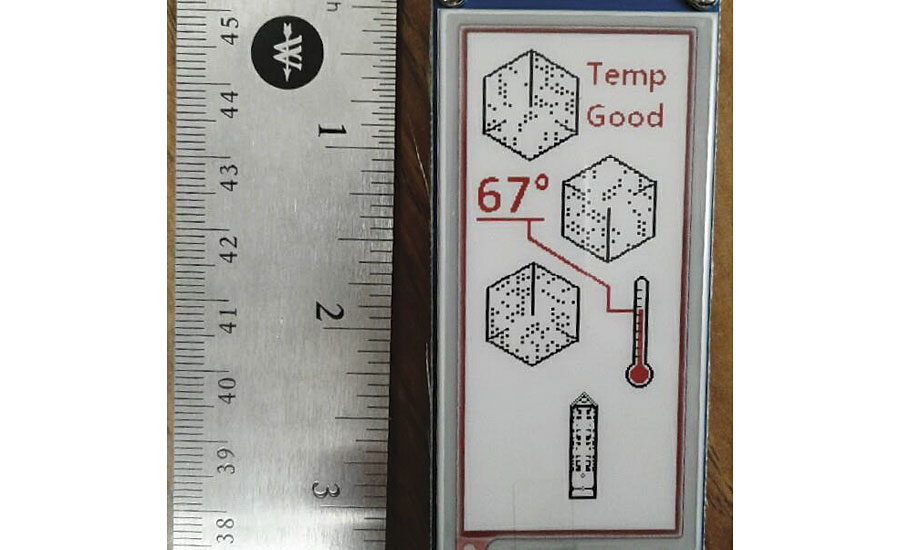

Electronic ink film is created as a grid of electrically reprogrammable particles that are less than 100 microns each that can be used to create flexible signage, labeling and screen displays. One of the unique properties of the particles is that they can become reflective or light absorbing and remain in that state permanently without the need for power. Electrical signals in the form of pulsed waveforms are used to excite the particles into discretely programmed states of black, white or red (Figure 8). The display film is flexible and can be reprogrammed down to the pixel level. There are also segment and block modes for the particles to allow large areas to change colors or thermal properties such as reflective or black body radiating thermal collectors.

FIGURE 8 » Electronic ink film is created as a grid of electrically reprogrammable particles that are less than 100 microns each that can be used to create flexible signage, labeling and screen displays.

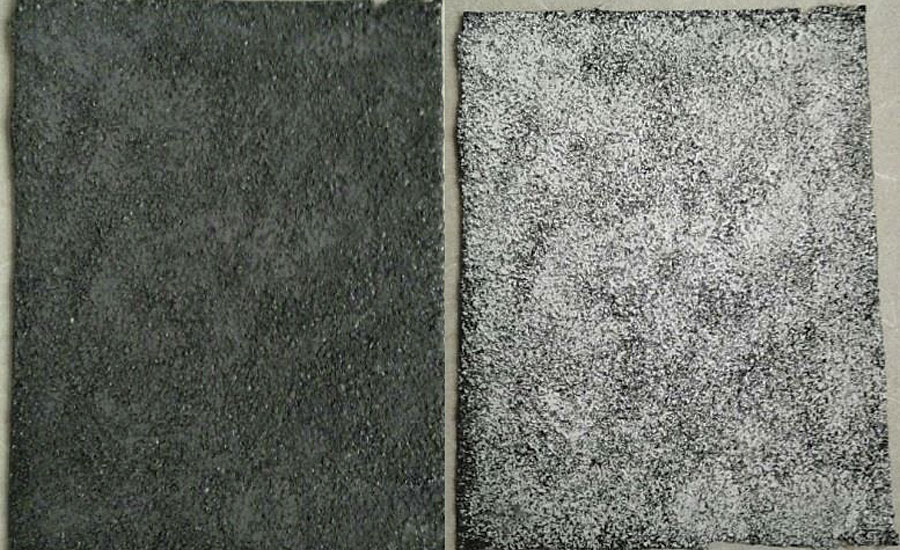

Thermochromic polymer particles can be used to coat a surface such as asphalt shingles to allow color changes to the surface-applied particles based on temperature. Figure 9 shows an example of 90 °F trigger programmed particles that reflect light in the summer and turn black in the cooler months in order to absorb heat in the winter. The purpose of the coating is to allow modification to existing production methods while providing a variety of color mixtures and patterns. It is also possible to create other building material solutions using this methodology including inside walls, ceilings and counter surfaces. In some cases the material itself could be injection molded or extruded to provide a functional composite material solution.

FIGURE 9 » Thermochromic polymer particles can be used to coat a surface such as asphalt shingles to allow color changes to the surface-applied particles based on temperature.

The hybridization of these and other smart materials is making its way into other materials such as paints and coatings. One example of this is the recently discovered state of carbon known as graphene, which allows structural enhancements that can be mixed with a carrier component and grown onto a substrate. The end result can form a lattice structure that creates extremely strong bonds structurally as a hexagonal grid. One of the important properties of this material as a lattice is the ability to conduct electricity. This means that the advancements of sensors and computing devices are abundant.

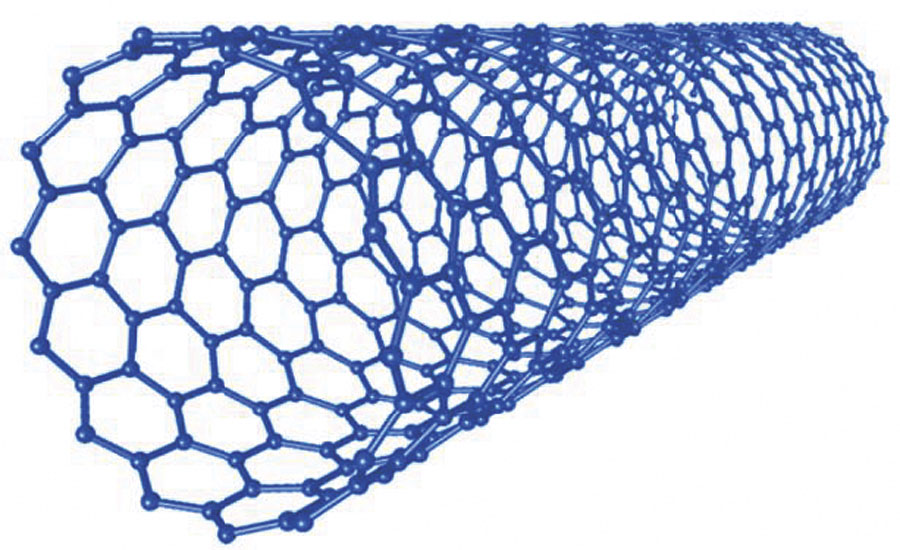

One of the most exciting areas of research into smart materials is in the field of carbon forms such as Fullerene C-60 (Buckyballs), carbon nanotubes (CNT) and graphene. Figure 10 shows a suspension of CNT that can be used as a coating, paint or adhesive when mixed in production with an appropriate carrier material. Carrier materials such as silicone rubber, epoxies and acrylic paints can provide lattice structures that enhance elasticity, impact resistance and resonant tolerance such as damping properties.

FIGURE 10 » A suspension of CNT that can be used as a coating, paint or adhesive when mixed in production with an appropriate carrier material.

The electrical conductive properties of the carbon additives can create a hybrid material that can be used to create sensors and actuators to tune or de-tune resonant vibrations. The hybrid composites can also be used to change durometer and response to shock through electrical and/or thermal excitation. Thermal heating modes can create “distributed warming” by conducting an electric current through the hybrid composite to create solutions such as avoiding brittle carrier material characteristics in the cold.

Plastic and epoxy carriers can be formed and molded into strategic shapes based on application or to exploit physical vibration characteristics based on strategically generated waveforms for material displacement. Applications include sound damping and active noise canceling. Flexible silicone adhesives, gaskets, washers and O-rings can be easily formed to provide programmable response to vibration, pressure, temperature or other electromagnetic properties. Externally powered warming caulk can be created that can offset humidity-based fogging on glass surfaces or defrost cold surfaces.

Carbon nanotubes form a contiguous lattice structure during the curing process of the carrier that provides an evenly distributed electrical network throughout the hybrid composite material. One of the inherent properties of CNT lattice structures is the ability to absorb electrostatic discharges (ESD), which can destroy electronic devices. This makes hybrid composite CNT smart materials attractive as electrical safety improvement solutions. Applications such as CNT coatings and potting compound adhesives can become a solution for thermal dissipation as well as energy discharge surface enhancements.

Carbon nanotubes and graphene can be structured together as a lattice formation in a complementary manner that can form electrical sensory networks including the formation of a functional field effect transistor (Figure 11). With this ability to become a smart material hybrid functioning as a transistor we enter a new frontier of semiconductor research that takes smart materials beyond the perception of spectacular to a true functioning computer circuit within the materials of tomorrow.

FIGURE 11 » Carbon nanotubes and graphene can be structured together in a lattice formation in a complementary manner that can form electrical sensory networks.

Conclusion

Today’s smart materials can be realized in the form of solids, adhesives, coatings, paints and liquids. They can provide rigid or flexible solutions that are resilient and temperature-stable while absorbing undesirable vibrations. The capabilities may seem like magic today, but they will someday seem as standard as a thermostat. Be ready to embrace the features and functions of tomorrow that will exploit the benefits of the attributes contained within smart materials. They are taking over the world… and that’s a good thing.

For more information, email d.strumpf@windgo.com or visit www.windgo.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!