Artisan-Style Three-Coat System Makes Waves in the Architecture Field

Artisan 3.5

Artisan 3.5

Artisan 3.5

Artisan 3.5

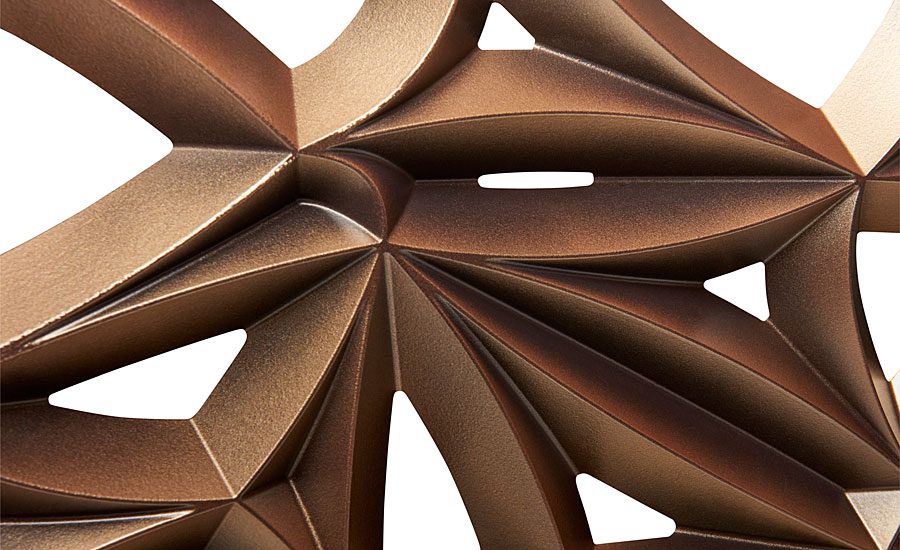

Dura Industries, reputable color developer and applicator of liquid PVDF and powder coatings, teamed up with Valspar, frontrunner in the international coil and extrusion architectural coatings industry and part of Sherwin-Williams Extrusion Coatings, to create and coat the renowned façade of the Smithsonian National Museum of African American History and Culture. For this specific project, Dura Industries implemented a hand-painted five-coat system for the first time in the company’s history. What resulted after project completion, apart from the phenomenal structure, was the development of an Artisan style coating using a Dura three-coat system.

To achieve the desired shade for the new museum, 3,600 metal wall panels were hand-coated by Dura’s production team. The metal wall panels were coated with a five-coat system – two layers of primer and three of the coating itself, achieving the envisioned hue of copper. Valspar provided multiple custom colors of its Fluropon® exterior architectural coating which were then mixed to the desired shades to achieve what would eventually be known as the Artisan 3.5 coating. Dura first developed 4 colors from which the Smithsonian design team selected African Sunrise. African Sunrise became the base color from which Dura then added other Valspar blending base colors to achieve the right shading effect when applied over a barrier coat in a standard shade of Black.

The two layers of primer with the five-coat system were necessary to create an even appearance for the rough surface of the sand-casted aluminum metal wall panels used on the new museum. After the development of the structure, the Dura team saw opportunity in their capability to create a uniform look consistently across thousands of metal panels. Since the use of sand-casted aluminum is unconventional within the industry, the first two layers of primer are not necessary on traditional materials. It was through this experience that the sought-after Dura three-coat Artisan style system was developed.

There are many things that set Dura Industries apart in addition to its new three-coat Artisan style system. To start, Dura blends 70 percent of coatings in-house, allowing the production team to achieve custom shades and make each project personal. Blending shades in-house also makes the process more efficient, providing customers with the desired coating in a timely fashion. Furthermore, the Dura production team has the skillset to consistently replicate their work, producing hand-painted metal panels that are uniform in shade and distribution.

After more than 40 years in the architectural coatings business, Dura Industries shows no sign of slowing down. Due to its fantastic reputation and ability to deliver, Dura has high demand for their offerings in quality craftsmanship. Providing both extrusion and custom options of liquid PVDF and powder coatings, the new three-coat Artisan style system has brought a new aspect to Dura’s repertoire – setting it apart from others in the industry.

To learn more, visit www.duraindustries.com.

By Dura Industries

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!