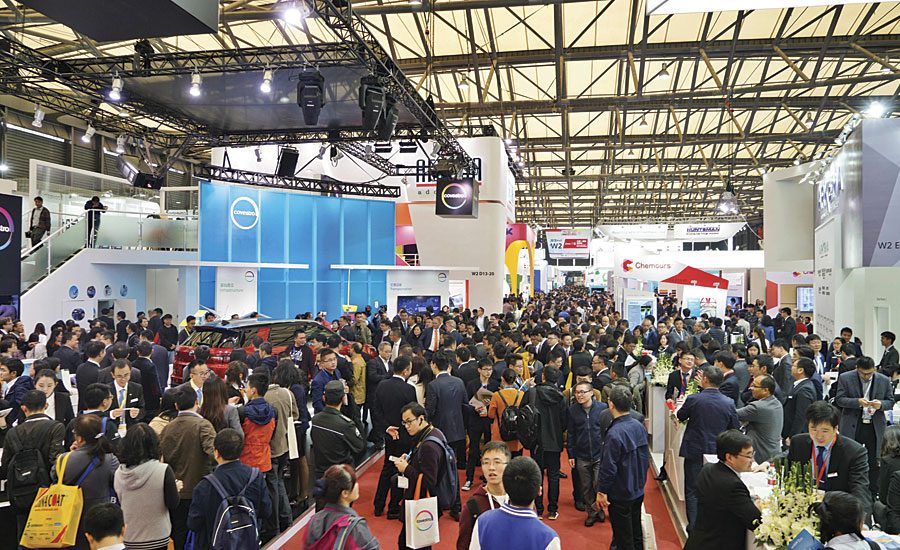

ChinaCoat 2017 Attracts Record Number of Visitors

Covestro's Michael Friede.

The DCM press conference.

ChinaCoat 2017 recorded outstanding results from both exhibitors and visitors, underlining the region’s continuous support of the industry. The show attracted a record number of visitors - growing by more than 12% and 16% respectively as compared to the 2016 Guangzhou and 2015 Shanghai events. ChinaCoat 2017 organizers report 34,425 registered visitors, including 29,262 domestic and 5,163 overseas visitors, as well as 1,210 exhibitors from 34 countries/regions, including 193 new exhibitors. Total gross exhibition area increased by 32% from 2016.

Following is a snapshot of what some of the industry’s suppliers featured at the event.

Ashland’s Thickener Products for Waterborne Coatings

Ashland highlighted its comprehensive solutions for waterborne industrial and architectural coatings. Aquaflow™ nonionic synthetic associative thickeners (NSATs) for high-performance waterborne paints and coatings build rheology through self-association and interaction with other ingredients. Easy-to-handle Aquaflow liquid rheology modifiers are based on hydrophobically modified polyacetal-polyether chemistry and are often drop-in replacements for urethane-type thickeners.

In waterborne latex paints, Aquaflow XLS NSAT grades improve the usability and efficacy of paints and coatings. They deliver virtually drip-free application, better viscosity retention after tinting, and provide outstanding flow and leveling. This helps eliminate brush marks and enhances applied hiding, enabling fewer coats while achieving beautiful, lasting finishes.

Natrosol™ and Natrosol Plus are thickeners for waterborne coatings. They are nonionic, free-flowing powders that are based on hydroxyethylcellulose. Natrosol offers pseudoplastic or shear-thinning characteristics, biostability and best-in-class color compatibility.

Drewplus™ foam control agents are nonionic blends of hydrophobic silica, silicones and paraffinic oil, and are formulated for use in water-based coatings. These highly efficient foam control agents offer easy incorporation and quick bubble break performance, with excellent persistence and compatibility. Because Drewplus functions as an air release agent, it is particularly effective on microfoam in spray-applied industrial coatings.

“Growing environmental awareness and stringent legal regulations are driving increased demand for waterborne coatings in China,” said William Zhao, General Manager, Ashland Specialty Ingredients Greater China. “Replacing solventborne coatings with high-performance waterborne alternatives offers many advantages, including reduced solvent exposure and less hazardous waste disposal. Ashland’s comprehensive portfolio of rheology modifiers and specialty additives can help simplify the manufacturing process and deliver key functional benefits to industrial and architectural paint and coating formulations.”

BYK’s Additive Portfolio for Water-Based Applications

BYK showcased numerous innovations and focused on differentiated water-based additive solutions that the company is using to satisfy the needs of the Chinese market.

Environmentally friendly systems are becoming increasingly important worldwide. As a result, BYK launched two new wetting and dispersing additives for aqueous systems in 2017, DISPERBYK-2080 and DISPERBYK-2081. Both additives offer optimal dispersion and stabilization of pigments and fillers, without impacting the water, corrosion and stain resistance of the coating system. In this way, modern, solvent-free additives emphasize the current trend for environmentally friendly problem solving while also offering extraordinary performance, especially in wood, furniture and protective coatings.

Optimal rheology allows for perfect processing and application. The two new associative thickeners for the water-based additive range, OPTIFLO-T 1010 and OPTIFLO-H 7625 VF, provide the coating system with a bespoke rheology profile in the respective coating application range. While OPTIFLO-H 7625 VF dramatically increases viscosity in the low-shear range and generates highly pseudoplastic flow behavior, OPTIFLO-T 1010 offers a near-Newtonian rheology profile with increased viscosity in the high-shear range, and also delivers on the environmentally friendly front. Both liquid products are free of VOC, APEO and tin.

Clariant’s Additive Solutions are Tailored to Local Needs

Clariant introduced new additive solutions developed to meet the specific needs of the Asian coatings market. The focus of the new solutions on aspects such as safety, UV protection and greater environmental compatibility is of particular relevance to China as it is experiencing a continuing boom in building, infrastructure and maritime projects. Last year, 84 skyscrapers over 200 meters tall were constructed in China and the country will build 66 new civil airports on its mainland within the next five years. In addition, its merchant vessels fleet has expanded almost three-fold in the past three years. The world’s 2nd largest economy is placing huge emphasis on the construction industry to ensure structures and cities are safe and sustainable.

“Our new innovations will enable formulators to keep up with the trend towards more eco-friendly and low-emission coatings, as the transition away from solvent-based coatings continues,” says Stephan Lynen, Head of Clariant BU Additives. “We have new products for waterborne and powder coatings for use on a broad range of substrates, indoors and outdoors. But we appreciate that moving completely away from solventborne coatings is still not possible in all situations, so we continue to develop additives to improve these systems as well.”

A typical example of Clariant’s latest innovations is light stabilizer Hostavin® TB-03, a high-performance synergistic combination of a UV absorber and a radical scavenger containing neither toluene nor xylene and suitable for both water- and solventborne systems. Two more light stabilizers, Hostavin 3070 P and Hostavin 3070 Disp, offer a “label-free” alternative to traditional HALS currently used in solventborne and waterborne systems respectively.

Further new introductions provide sustainability benefits for customers producing powder coatings and intumescent coatings. AddWorks® IBC 251 produces an improved tribo-charge effect that reduces over-sprays in powder coating materials and also improves heat stabilization during the baking process. Exolit® AP 428, a new flame retardant based on ammonium polyphosphate, greatly simplifies the production of waterborne intumescent coatings; it can be used as a flame retardant in textile and plastics applications as well.

Clariant also launched several new Ceridust® wax-based additives for wood and powder coating systems. Ceridust 2740 TP, for example, a blend that is easy to incorporate into water- and solventborne systems, is the company’s response to the trend for coatings with higher clarity, while Ceridust 9322 F TP, a PTFE-modified product, provides very high scratch resistance levels in solvent-based coatings and also results in a smooth surface touch; it can also be used in powder coatings to substantially reduce surface friction and improve mar and scratch resistance.

Clariant announced in early 2017 that two new additives facilities at its existing site in Zhenjiang are scheduled to come on-stream in the second half of 2018. “These facilities will enable us to offer innovative high-end solutions tailored to the specific needs of the local coatings, inks and plastics industries, with accelerated response times,” says Lynen.

Covestro Pushes Boundaries

At Covestro’s ChinaCoat Press Briefing, Michael Friede, Head of the Coatings, Adhesives and Specialties (CAS) Business Unit, discussed the company’s theme at the show, as well as local trends and the latest company products. He noted that 2017 is the 80th anniversary of the company’s invention of polyurethane (PU), and with that inspiration, Covestro’s focus at ChinaCoat was “pushing boundaries”. Friede said that the company is trying to make the world a brighter place in a sustainable manner, and is also trying to not just supply products, but is finding partnerships throughout and across the value chain to develop new technologies.

When asked about the latest regulations and the “Belt and Road” initiative imposed by the Chinese government, Friede commented that Covestro is very happy with this overall direction, as it fits nicely in how they want to develop in the market. “We can contribute to these targets, and we can benefit as well,” he said. He also noted that the Belt and Road initiative has a logistical benefit, in that it will increase the speed with which companies can import products. The new rail connection between China and Europe will reduce transport time from two or three months to 20 days.

Covestro has collaborated with Chinese partners to innovate high-performance and environmentally friendly PU coating technology, which has gained breakthroughs in a number of infrastructure construction application areas, and which further support the initiative.

For railway transportation, Covestro and Shanxi Huabao Coating jointly developed Bayhydurâ + Bayhydrolâ easy-to-spray waterborne 2k PU coating technology for application in large vehicles, which can reduce VOC emissions by two-thirds, double the service life and has already been applied to 40,000 vehicles. These vehicles have been exported to various markets such as Asia, Australia and South America.

For infrastructure, Covestro developed Pasqiuck™-based waterproof coating solution for the construction of high-speed rail, bridges and ports, which is easy to use, provides excellent appearance and has low VOC emissions. In addition, Covestro and Sherwin-Williams/Valspar have successfully for the first time applied waterborne PU coatings in the domestic construction machinery industry.

For housing industrialization, Covestro partnered with Nippon Paint to develop waterborne 2K PU clearcoat for Nippon’s prefabricated exterior wall panel. The technology helps to improve the durability of exterior walls and reduce VOC emissions in application.

Covestro has been dedicated in driving industry collaboration to foster commercialization of material innovation. Together with Hunan Xiangjiang Kansai Paint, Covestro has helped Changan Automobile upgrade its coating technology, which is applied on the newly launched SUV model CS55, displayed at the Covestro booth.

DCM Press Conference Sheds Light on Trends and New Products

Dow Coating Materials (DCM), a business unit of DowDuPont Materials Science Division, held a press conference as well. In attendance from Dow were Ashok Kalyana, APAC Business Director, DCM; Dr. Ian (Yaobang) Li, Commercial Leader, The Dow Chemical Co.; Dr. David H. Guo, R&D Director, The Dow Chemical Co.; Puay Koon Chia, Product and Marketing Director, DCM; and Alex Fang, Commercial Director, DCM Greater China.

Ashok Kalyana kicked off the meeting by introducing the theme for the 2017 ChinaCoat booth, “We Make Coatings Work Better.” Kalyana noted that the four key ways in which DCM makes this happen are: innovation, quality and consistency, commitment to sustainability, and commitment to meet the needs of the local market.

Green development is driving consumer preferences, market trends and regulatory needs to be environmentally friendly, energy efficient and safe, evident through increased demand for coating solutions that are water-based and low in VOC emissions.

When asked what impact the merger with DuPont has had on the DCM business unit, Kalyana noted that there is very little overlap in coatings between the two companies. But he did state that the DCM business is very excited about integrating Dow Corning technology as a result of Dow’s strategic ownership restructuring of Dow Corning Corp. DCM is planning to explore combining acrylic and silicone technologies to develop new high-performance coatings.

In terms of trends in the Asia Pacific region, Puay Koon Chia said that currently in China there is a big interest in products that are better for our health. DCM is seeing a lot of demand for formaldehyde-free coatings, as well as low-odor and low-VOC technologies. The company’s PRIMAL™ acrylic emulsion for kid’s paint is designed for interior paints with ultralow VOC and low odor. It not only meets the high standards of environmental and health requirements, but also provides excellent paint performance and functionality. The product incorporates both INVIZIPRO™ and FORMASHIELD™ technologies. INVIZIPRO provides excellent stain removal, washability and scrub resistance, and FORMASHIELD reacts with formaldehyde in the air to actively remove it and convert it into water vapor.

Other trends in the Asia Pacific region are coatings that save time and labor (as labor costs are predicted to rise), the conversion from solvent-based to water-based technologies (driven by government regulations), and a big marketing push to the re-paint market. With China’s successful economy and more disposable income, paint manufacturers are encouraging homeowners to renovate and re-decorate their homes.

DCM confirmed that plans for its new advanced materials manufacturing plant in western China are on track; it is expected to be operational in Q2 2018. The plant was announced in 2016 as part of Dow Greater China’s strategy to address growing customer needs for more innovative and cutting-edge solutions in the region’s architectural, industrial and paper coatings markets. When in full operation, it will have annual sales of approximately RMB 600 million, or US $92 million.

Other products featured at ChinaCoat include the following:

- PRIMAL™ SR-01 Solar Reflective Emulsion is a newly developed functional acrylic emulsion that improves solar reflection effects at low-, medium- and high-brightness coatings, to lower energy consumption in buildings. It provides excellent flexibility and dirt pick-up resistance, and offers durable and high solar reflection in long-term outdoor exposure.

- Dow’s industrial coatings continue to offer innovations aligned with evolving sustainability trends.

- PROSPERSE™ 200 Hydroxyl Acrylic Emulsion is designed for two-component (2K) water-based polyurethane topcoats, which can react with water-dispersible polyisocyanates. It delivers excellent hardness, scratch resistance and chemical resistance.

- MAINCOTE™ HG-100 Emulsion is designed for economic, one-component (1K) waterborne maintenance coatings as an alternative to solventborne alkyd paints. It offers good corrosion resistance, excellent early water resistance and gloss development.

Huntsman’s Theme: Reaching Out to Infinite Possibilities

Huntsman brought together its Advanced Materials and Performance Products divisions to showcase a wide range of products under the theme of “Reaching Out to Infinite Possibilities”.

Huntsman Advanced Materials’ ARA®Cool portfolio made its first appearance at ChinaCoat through an on-site ice sculpture. Designed to speed up the cure process between 0 °C and 10 °C, ARACool products enable coating formulators to break new ground in anticorrosion and protective paints. This new product series is suitable for oil and gas, marine, transportation and industrial maintenance applications. ARACool products meet the challenging regulatory requirements, and end users can work efficiently even under harsh conditions.

Huntsman Advanced Materials also showcased ARALDITE® epoxy resin and ARADUR® epoxy curing agent, the waterborne epoxy systems for coatings that offer very low VOC and minimized odor. Huntsman’s high-performance waterborne epoxy systems enable formulators to get the highest performance from epoxy, while adhering to environmental regulations.

LANXESS’s Environmentally Friendly Solutions

LANXESS showcased a comprehensive range of environmentally friendly solutions for the coatings industry with its four business units. The booth exhibited a variety of sustainable and innovative inorganic pigments; preservatives and fungicides to protect paints and coatings; urethane products used in special coatings, adhesives, textile sizing and other fields; and colorful solvent-free pigment preparations and colorants used in inkjet printing and stationery inks.

The Inorganic Pigments business unit is one of the world’s leading manufacturers of inorganic pigments, with a broad and innovative product range and acknowledged expertise in technical service. The business unit has a global presence with production facilities in Germany, China, and Brazil as well as with additional mixing and milling facilities in Australia, the UK, Spain and the United States.

LANXESS Urethane Systems is a world leader in hot-cast prepolymers and a leading manufacturer of specialty aqueous polyurethane dispersions, coating systems and polyester polyols. It offers specialized polyurethane systems know-how, global production capabilities, deep application expertise and decades of technical experience.

The Material Protection Products business unit highlighted its green anticorrosion mildew products, which represent the latest technology of environmentally friendly sterilization.

LANXESS also showcased a number of innovative solutions with environmentally friendly features from the Rhein Chemie business unit. For example, the Levanyl® LF and Levanox® LF aqueous pigments, and Bayscript® colorants for inkjet and stationery inks offer a wide variety of brilliant colors while meeting environmental regulations and the latest ecological requirements.

Lomon Billions Excited About Chinacoat

TiO2 experts at Lomon Billions, the biggest TiO2 pigment manufacturing company in Asia, were excited about Chinacoat 2017. “We’ll be promoting our wide range of high-performance LOMON® and BILLIONS® TiO2 pigments for coatings and inks including our highly durable LOMONR-996 pigment for interior and exterior coatings, our specialist BILLIONSTR52 pigment for printing inks, and our new BILLIONS BLR-895 pigment for coatings,” said Julie Reid, Marketing Director.

“We make our TiO2 pigments using both the sulfate and chloride process, says Reid. Our latest pigment for coatings is our new BILLIONS BLR-895 pigment, developed through consultation with our customers and made using the chloride process for excellent all-round performance in coatings.”

SONGWON’s UV Absorbers for Demanding Coatings Applications

SONGWON is expanding its range of ultraviolet absorbers (UVAs) for high-performance coatings with the launch of two new products, SONGSORB® CS 400 and SONGSORB CS 384-2. The two UVAs can both be used in combination with a hindered amine light stabilizers (HALS) such as SONGSORB CS AQ01, which was introduced at the 2017 European Coatings Show.

“The new UVAs provide coatings with outstanding protection against degradation due to high temperatures during processing and environmental impact during use. They therefore help to prolong the life of end products such as vehicles,” said Rosanna Telesca, Leader, Market Center Coatings at SONGWON.

Venator’s Titanium Dioxide and Performance Additives

Venator makes TiO2 white pigments, color pigments, additives and fillers for use in all kinds of coating and ink systems.

Eric Chong, Vice President of Venator in Asia Pacific, said, “This is our first time at Chinacoat as Venator – and we’re extremely excited for the show. We have 40 Venator experts coming along to Shanghai to talk to formulators about the cost, processing, performance and environmental benefits that our titanium dioxide pigments and performance additives can add to their coating capabilities. We have a strong footprint in Asia, with sales and technical support hubs across Asia Pacific and customer service support in Kuala Lumpur, Malaysia, in addition to our two manufacturing sites in Taicang, China and Teluk Kalong, Malaysia.”

WACKER’s Dispersions for Easy-to-Clean Applications and Binders for High-Performance Exterior Paints

WACKER presented two new polymer dispersions. PRIMIS® SAF 9000 is designed for the dirt-repellent treatment of walls, concrete and stone floors. This copolymer has a special composition that is both oil resistant and hydrophobic, making the end products resistant to many different types of stains – from coffee and lipstick to colored pencils. PRIMIS KT 3000 is a high-performance additive, which allows exterior wall paints and plasters to set quickly and reliably, even at low temperatures, making coatings resistant to the effects of weathering after a short time. WACKER also presented the dispersible polymer powders VINNAPAS® 5544 N for smooth and flexible surfaces such as diatom ooze and VINNAPAS 7031 H for decorative plasters.

Thanks to its special composition, the new PRIMIS SAF 9000 is both water and oil repellent. The acrylic ester-based dispersion contains extremely fine particles and therefore distributes evenly into the micro- and sub-micropores of the treated surface, which provides good mechanical properties, such as abrasion resistance and durability.

PRIMIS SAF 9000 can be used in dilute form for dirt-repellent treatment of decorative mineral surfaces, such as self-leveling flooring compounds and concrete floors. It provides long-term protection against the penetration of water- or oil-based substances into the pores without impacting the appearance or feel of the flooring.

PRIMIS SAF 9000 can also be used to formulate so-called “easy-to-clean” interior wall paints that are resistant to a whole host of substances – from tea and coffee to lipstick, mustard or colored pencils and mark pen.

The additive PRIMIS KT 3000, based on zinc acetate and polyethyleneimine, creates a kind of gel that distributes homogeneously in the coating and forms a stable polymer network even when atmospheric humidity is high and temperatures are only 5 °C. It considerably shortens the critical drying time to six hours for wall paints and plasters that are formulated with the additive. The product can readily be mixed with WACKER’s VAE dispersions of the VINNAPAS range. In this way, PRIMIS KT 3000 makes it possible to perform outdoor painting work in late autumn or spring in cooler regions, too.

The dispersible polymer powder VINNAPAS 5544 N is especially suitable for formulating highly flexible mortars with very good adhesion to inorganic and organic substrates and excellent scrub resistance. The product is free of odor. Without intentional add of formaldehyde, it enables the formulation of low-addition end products (formaldehyde <5PPM). It also offers high flexibility and easy-to-scrape properties. Meanwhile, with very fine particles, the product is perfect for applications that require very smooth surfaces, such as diatom ooze and skim coats. In addition to enhancing crack resistance, its excellent dispersibility can significantly improve the workability of final products.

VINNAPAS 7031 H is a flexible dispersible polymer powder with a hydrophobic effect and very good workability. Compounds modified with VINNAPAS 7031 H exhibit improved flexural strength, deformability, crack and whiskering resistance, as well as improved cohesion and adhesion to substrates. It also significantly reduces water absorption and shrinking percentage of decorative plasters.

ChinaCoat will return to Guangzhou on December 4-6, 2018.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!