Why Cure Wood With UV LED Lamps? Because It’s Cool.

From furniture and cabinet doors to parquet flooring, leading companies in wood manufacturing are embracing UV LED curing for wood coatings for several reasons, but mostly because it’s cool. Literally.

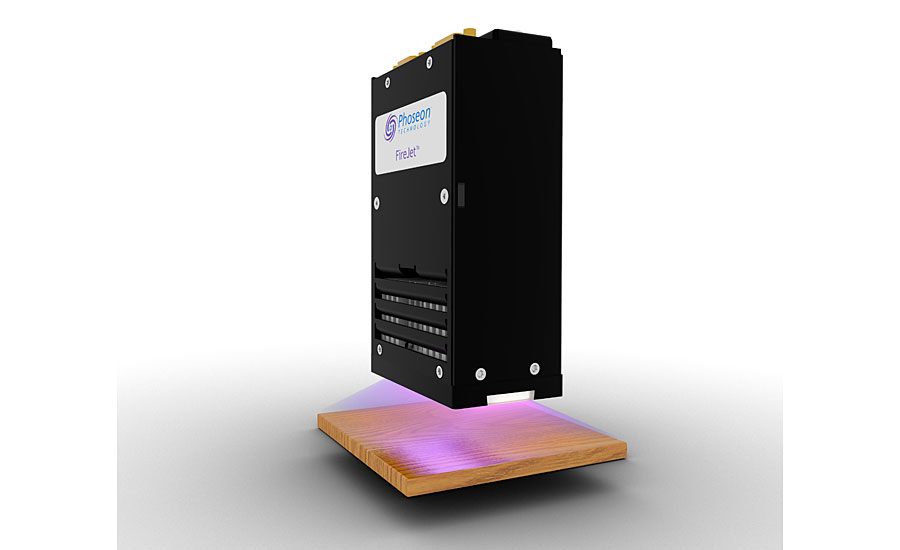

Phoseon Technology’s revolutionary UV LED curing raises work piece surface temperature less than half of traditional curing methods that utilize traditional UV or arc lights, which can heat the wood’s surface by as much as 60 °C.

Whether curing the b-stage or gel fillers, or hardening the surface coating, wood products can typically pass through as many as 10 UV curing stations during the finishing process. The extensive heat created by multiple curing stations utilizing traditional arc or microwave lamps can often damage the wood.

“Heat creates tremendous challenges in wood coating, particularly with woods with high resin or oil content, such as pine, fir, spruce and mahogany,” said Jennifer Heathcote, Regional Sales Manager at Phoseon Technology. “Heat brings the resins and oils to the wood’s surface, and that bleeding causes discoloration and problems with coating adhesion. UV LED curing systems transfer less heat to the work surface, which eliminates these issues and creates less product waste.”

In addition to yielding cooler substrate surfaces, Phoseon UV LED systems operate at temperatures that are often less than 10 percent of traditional lamps. For example, the bulb in a conventional system generally runs with a quartz surface temperature between 900 and 1,200 °C. This temperature, as well as the infrared wavelengths of the bulb, is ultimately transferred as heat to the wood products. UV LED lamps also last longer and use less energy than traditional curing methods. With their lower operating temperature and energy efficiency, coupled with the elimination of exhaust, UV LED curing can increase total energy savings by as much as 90 percent.

“Conventional UV systems require the use of extraction to remove heat and ozone, both of which are eliminated with the use of UV LED,” said Heathcote. “In addition to the extra energy needed for exhaust and potential make-up air, air management is a concern in performance applications such as surface curing for furniture and cabinetry where dust and airborne contaminants can come in contact and ruin the finish. UV LED curing reduces or eliminates that concern.”

Furthermore, the UV output from Phoseon’s UV LED curing systems is consistent over time and more uniform along the length of the device than arc and microwave lamps, which often have variations in UV intensity from one end of the lamp to the other, especially with the long lamps needed to process the four-foot-wide boards common with many wood lines.

“That means tighter process control, less downtime, greater plant utilization and an overall better and more consistent product,” said Heathcote. “In the end, that leads to higher yields and reduced scrap for manufacturers.”

Heathcote notes that Phoseon’s UV LED curing, which in addition to wood curing also is used in a wide range of other applications, such as printing on paper, film, plastic and glass, is a safer and more environmentally friendly alternative to curing with mercury-based lamps

“The elimination of noise from extraction fans and blowers, lower energy consumption, the elimination of both ozone and mercury, in addition to a cooler working climate, means UV LED curing makes for an overall safer and more comfortable workplace environment,” said Heathcote.

By Phoseon Technology

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!