Easily Dispersible Pigments

Modified Organic Pigments for Improved Sustainability and Performance

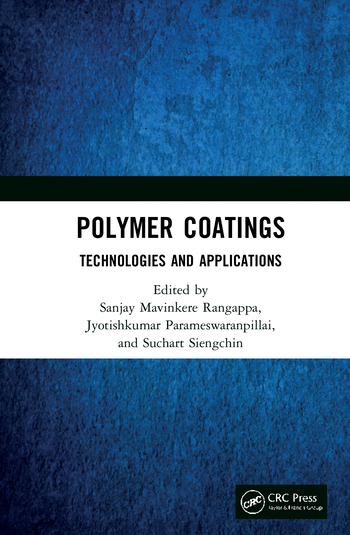

Figure 1

Figure 2

Paint and coatings manufacturers are looking to improve the sustainability profile of their companies and products while maintaining the same level of performance in their paints. Easily dispersible (ED) pigments help improve the sustainability profile of dispersions from the production process through the final paint sale to consumers.

Easily Dispersible Pigments

ED pigments offer paint manufacturers best-in-class performance in both waterborne and solventborne applications while reducing production time, saving money and decreasing energy consumption.

In traditional pigment powder production, pigment particles form aggregates, which create agglomerates. To obtain optimal color properties, these particles must be uniformly dispersed throughout the resin solution, which requires agglomerates to be separated in a dissolver and then run through a bead mill for two to 48 hrs. With our ED pigments, a dispersing additive is added to pigment surfaces during the manufacturing process, which surrounds aggregates with chemical spacers. The additive changes the surface polarity, resulting in a greater distance between aggregates (Figure 1). Reagglomeration is prevented by the weakening of attractive forces between pigment particles. The addition of the dispersing additive during pigment production eliminates the most energy-consuming step in paint production – the bead milling step. The result is a modified organic pigment that can be dispersed using a high-speed dissolver without agglomeration (Figure 2).

With these pigments, production time is decreased up to 85 percent, with an average 30 min required for dispersion to full color strength. Paint manufacturers can expect cost savings of up to 30 percent, achieved through the shorter processing and production time and increased flexibility in capacity. Additionally, cost savings and an improved environmental footprint can be realized through the use of up to 90 percent less electricity and the generation of less polluted wastewater during paint production.

All of these pigments also hold Clariant’s EcoTain® Portfolio Value Program certification label. The EcoTain certification is awarded only to products that undergo systematic, in-depth testing using 36 criteria representing the social, environmental and economic dimensions of sustainability, and prove best-in-class performance and sustainability excellence. During the certification process, products are evaluated on a four-phase life cycle, from sustainable design to ecointegration.

Easily dispersible pigments have been successfully tested against similar pigments in various coatings systems including alkyd (air drying and baking enamels), polyurethane, polyester (saturated and unsaturated) acrylic (UV curing, e.g. epoxy acrylate resins) and epoxy systems.

While all ED products in our range are organic pigments, they can be co-dispersed with inorganic pigments and are ideal for the production of colorants for low-VOC paints.

A Biobased, ED Pigment for Waterborne Systems

ED pigments are available in a variety of color options, including quinacridone pigment Hostaperm® Pink E (Pigment Red 122), derived from renewable raw materials. Clariant predecessor Hoechst AG invented the chemistry for Pigment Red 122 that continues to be used around the world in architectural, industrial and automotive coatings applications. The majority of Hostaperm Pink E is utilized in architectural applications.

Hostaperm Pink E is manufactured using biosuccinic acid from sugars extracted from corn, sorghum and other high-volume agricultural crops. The biosuccinic acid is supplied by renewable chemical developer, Myriant. Source materials for Myriant’s biosuccinic acid do not compete with the food supply. In the synthesis of quinacridone pigments, a large part of the aromatic molecule is synthesized by starting from a nonaromatic biosuccinic acid building block accessible from biochemical processes. To turn the uncolored crystals of biosuccinic acid into a bright pink pigment, the quinacridone -an organic compound with the molecular formula C20H12N2O2 -must be synthesized. The molecule has a classic heterocyclic structure, comprising a chromophore system of five fused, alternate 4-pyridone and benzene rings. The pigment has an improved ecological footprint.

As a biobased quinacridone pigment, Hostaperm Pink E is a magenta shade with high tint strength and fastness properties. In this pigment, dimethylquinacridone has two substituents, which results in absorption of green and yellow wavelengths. The resulting color is a bright shade of pink.

In testing, Clariant has proven that quinacridone pigments manufactured from biosuccinic acid perform as well as petrochemical-based pigments, have the same performance and thus require no reformulation. The renewable raw materials improve the carbon footprint of the pigment.

The conversion to an easily dispersible waterborne (EDW) form during pigment production allows Hostaperm Pink E-EDW to disperse relatively quickly into the waterborne systems as the emulsifier additive protects pigment molecules from agglomeration, ensuring color strength is achieved in a short time. Additionally, the pigment offers high weather fastness, high overspray fastness properties, and high tinting strength and brilliance. EDW pigments are available in seven color indices, P.Y.74, P.Y.154, P.O.36, P.R.168, P.R.254 and P.R.122, with two additional indices in development.

Color strength of ED pigments is dependent upon a few factors, including the additive used to reduce agglomeration, the geometry of the dissolver, the peripheral speed of the mixer (18-25 m/s), and the use of the doughnut effect for viscosity and color concentration. Using the Dispermat AE4-C dissolver by Getzmann at a speed of 8,000 to 10,000 RPM with a disc diameter of 40 mm, EDW pigments are dispersed for 30 min at 40 °C with optimum pigment loading. In the case of Hostaperm Pink E-EDW, the dispersing concentration is 35 percent.

In comparison to conventional pigments in a bead mill, we have observed that the color strength of Hostaperm Pink E-EDW in both emulsion paint and long oil alkyd white reduction is comparable to dispersion using a bead-mill process.

Improved Chroma and Opacity

Novoperm Orange HL 70, a red shade orange benzimidazolone pigment, is a leading global grade of opaque Pigment Orange 36, initially invented by Hoechst AG. While the opaque grade of Pigment Orange 36 was introduced to the market 50 years ago, our scientists have recently made it even more brilliant. This pigment is ideal for industrial and automotive applications, with improved weather fastness, overspray fastness and tinting strength.

When dispersing Novoperm Orange HL 70 into a waterborne system using the bead milling process, our scientists observed a loss of chroma. As with other ED pigments, a dispersing agent is added to Novoperm Orange HL 70 during the production process to create chemical spacers between molecules so the pigment molecules resist agglomeration without the use of a bead mill. The chroma loss rate for Novoperm Orange HL 70-EDW is four times lower in a high-speed dissolver, and full color strength is developed after 30 min. In addition, when processed in a high-speed dissolver, the pigment can be used to improve opacity by “smart” color formulation compared to other Pigment Orange 36 grades processed in the bead mill. This pigment allows formulators to create more chromatic new shades and to match existing shades with a significantly higher opacity.

Solvent-Based Sustainability for Industrial Applications

In addition to offering ED pigments for waterborne applications, ED pigments for solventborne applications, including industrial coatings, are also available. Easily dispersible solventborne (EDS) pigments have been successful time and time again in industrial coatings, including coatings that improve public safety in cities around the world. We have worked with companies such as Transpo Industries in the development of custom-blended EDS pigments for methyl methacrylate-based colored pavement marking applications such as pedestrian walkways, bike lanes and bus lanes.

“Our colored pavement projects require high-performance pigments that maintain vibrancy and durability over several years and in many different climates,” said Michael S. Stenko, CEO of Transpo. “Clariant’s customized solutions, developed using their easily dispersible pigments, meet these requirements and fit well with our company’s sustainability goals.”

During evaluation of EDS pigments in multiple coatings systems, we have observed that these pigments are widely compatible and easily blended to achieve thousands of color possibilities. The additives that make ED pigments resist agglomeration do not show adverse effects on paint properties such as pot life and film hardness in two-component PU systems, or drying time of air drying systems or overall weather fastness. Weather fastness remains comparable to traditional pigments in solvent-based applications.

Our EDS pigment product line includes a variety of pigment colors in the pink, yellow, orange, red, violet, blue and green ranges.

Conclusion

ED pigments offer paint manufacturers best-in-class performance in both waterborne and solventborne applications while reducing production time, saving money and decreasing energy consumption. Continued innovation and commitment to sustainability are driving further additions to our ED pigment product range that will help formulators enhance the sustainability of products they sell to end consumers.

For more information, www.clariant.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!