Understanding Spray Coating Performance

Using Powder Rheology

Powder coating can deliver many advantages including more-efficient operations, waste reduction, and the absence of solvents and the associated volatile organic compounds (VOCs). This makes it an environmentally sound and financially attractive alternative to traditional liquid finishing, and many manufacturers are therefore considering powder coating for a wide range of applications. However, in order to optimize coating operations and enhance product quality, it is critical to understand how a powder will behave in transit, during storage and ultimately in the final process. Powders are complex assemblies of solids, liquids and gases, and the way they can behave certainly provides their industrial value, but it also makes it challenging to characterize them and predict how they will perform. There are many traditional methods for testing powders, but the limitations to these methods are quickly becoming recognized as applications become more demanding and the need to test powders under process-relevant conditions is acknowledged as being crucial.

The Challenges of Spray Coating

In spray coating, a fine powder is drawn from a storage chamber before being fluidized and ejected through a charged nozzle onto a substrate. It is essential that the powder is effectively and consistently fluidized without the formation of agglomerates that may block the nozzle and affect the charging of individual particles. This ultimately leads to poor adhesion or the formation of agglomerates on the surface of the substrate. Uniform flow from the storage chamber is also important, as any evidence of erratic flow will affect the fluidization process and result in a poorly distributed product.

Identifying powders that are conducive to efficient performance allows compatible raw materials to be identified or new formulations to be optimized without running samples through the process in order to assess suitability. This generates significant savings in terms of time and resources, and minimizes the number of products rejected for being out of specification.

Assessing Process Performance and Product Quality

This article presents a case study in which three polymer powders were used in a corona charging spray coating system. Despite being almost identical in terms of their particle size and particle size distribution, the three materials behaved very differently in process. Sample A was categorized as being “good”, as it flowed through the nozzle well and adhered consistently to the substrate. Sample B was only considered to be “acceptable” and Sample C performed poorly in both critical areas; it regularly blocked the nozzle and fell away from the surface of the substrate during subsequent transportation.

Samples of the three materials were analyzed using an FT4 Powder Rheometer®. Clear and repeatable differences were observed in the test results, which rationalized the in-process variation. In addition, the data could then be used to provide criteria against which future raw materials and formulations could be assessed.

Analysis of Test Results

Sample A generated the highest basic flowability energy (BFE) and specific energy (SE) values (Figure 1), which together indicate greater cohesion as well as higher levels of inter-particular friction and mechanical interlocking. In contrast, Sample C generated the lowest BFE and SE values. This suggests that a certain degree of inter-particular cohesion is required to form a uniform coating on the substrate.

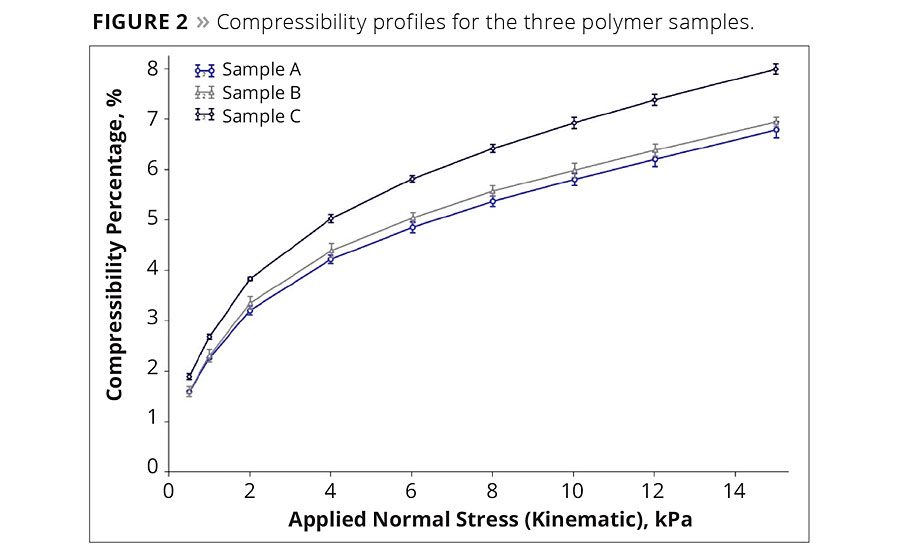

Sample C was the most compressible of the three samples (Figure 2), indicating a greater sensitivity to applied stress. Powders that compress easily will consolidate more under their own weight and are therefore more likely to be problematic when required to flow following storage. They are also likely to be more prone to agglomeration, which is typically detrimental to many unit operations but will certainly have a negative impact on the spraying and charging stages of the spray coating process.

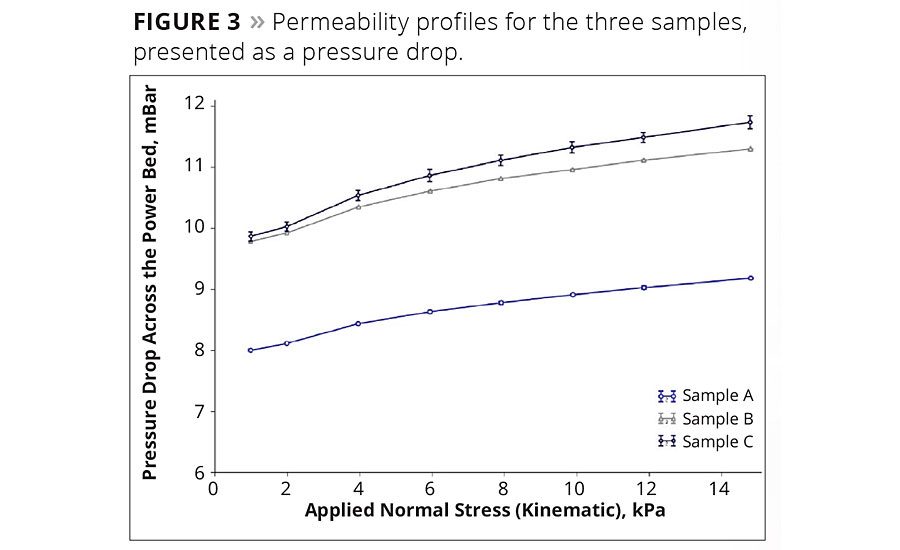

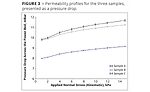

Sample A generated the lowest pressure drop across the powder bed (Figure 3) when a controlled quantity of air was introduced to the sample. This indicates higher permeability, which is typically associated with free-flowing materials. Poor permeability is known to cause erratic, pulsatile flow, which can lead to variation in the distribution of the powder within the fluidization chamber and inconsistent flow of the fluidized powder.

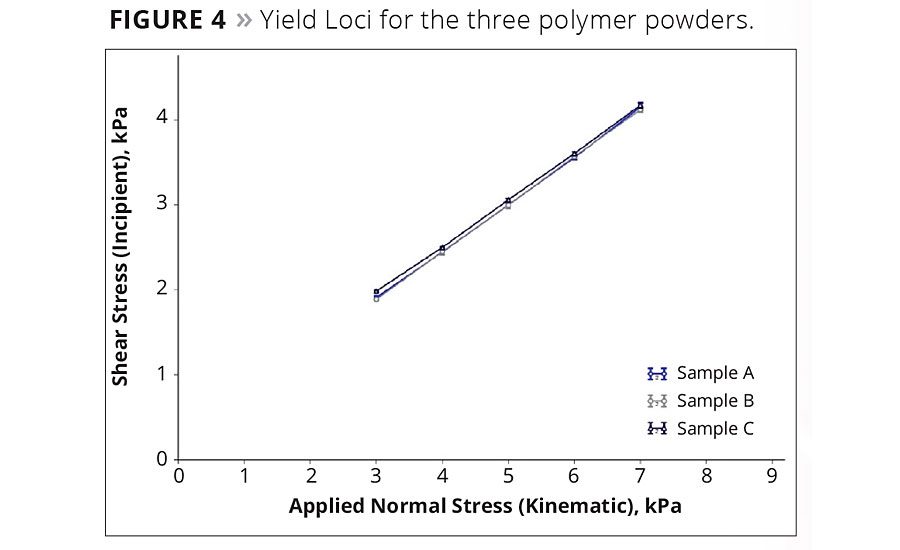

Interestingly, no differentiation was observed in the results of shear cell tests on the three powders. The three Yield Loci shown in Figure 4 are almost identical with the measured shear stress values, all being within 2.5% RSD. Shear cell tests measure how easily a highly consolidated powder at rest will transition into flow. The results here suggest that the test conditions are not relevant to the dynamic, low-stress environment that prevails in a spray coating application.

Conclusion

Sample A generates the highest BFE, SE and permeability values, and the lowest compressibility value. This suggests that a certain degree of cohesion is required to form a uniform coating and that susceptibility to agglomeration and/or erratic flow is likely to be detrimental to the process. Sample C, with the lowest BFE and permeability, and the highest compressibility, is most sensitive to compaction during storage and conveyance, and is more likely to form agglomerates that can block the nozzle and result in inconsistent charging.

The case study presented here illustrates the importance of testing powders under conditions that simulate the process environment. Spray coating is typically a very low-stress, dynamic process with small quantities of powders being stored, conveyed and fluidized. In order to understand how powders will behave under such conditions, it is essential that the tests employed subject the sample to the same diverse conditions. The lack of differentiation in the shear cell test results reinforces the need to generate process-relevant information. Similarly, no single parameter or test method is capable of describing how a powder will behave across a range of conditions. Two powders may exhibit a similar response in a certain stage within a process but behave completely differently in another. This further highlights the need to identify tests that are representative of a given part of the process. For example, the compressibility test shows very similar results for Sample A and Sample B but the BFE values are significantly different. This suggests that these two samples may exhibit similar levels of compaction when subjected to an applied stress but will respond differently when required to flow under forced, dynamic conditions.

The multifaceted approach to powder characterization provided by a powder rheometer made it possible to quantify properties of three very similar powders and explain why they perform so differently in a typical spray coating application.

For more information, visit www.freemantech.co.uk.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!